Gap measurement tool and gap qualified rate measurement method

A measurement tool and measurement method technology, applied in the field of measurement, can solve the problems of inability to guarantee the production takt, complicated and unrealistic adjustment of vernier calipers, etc., to meet the requirements of high-efficiency measurement of size, wide market promotion and application prospects, and convenient size measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention more clearly, but the protection scope of the present invention is not limited thereby.

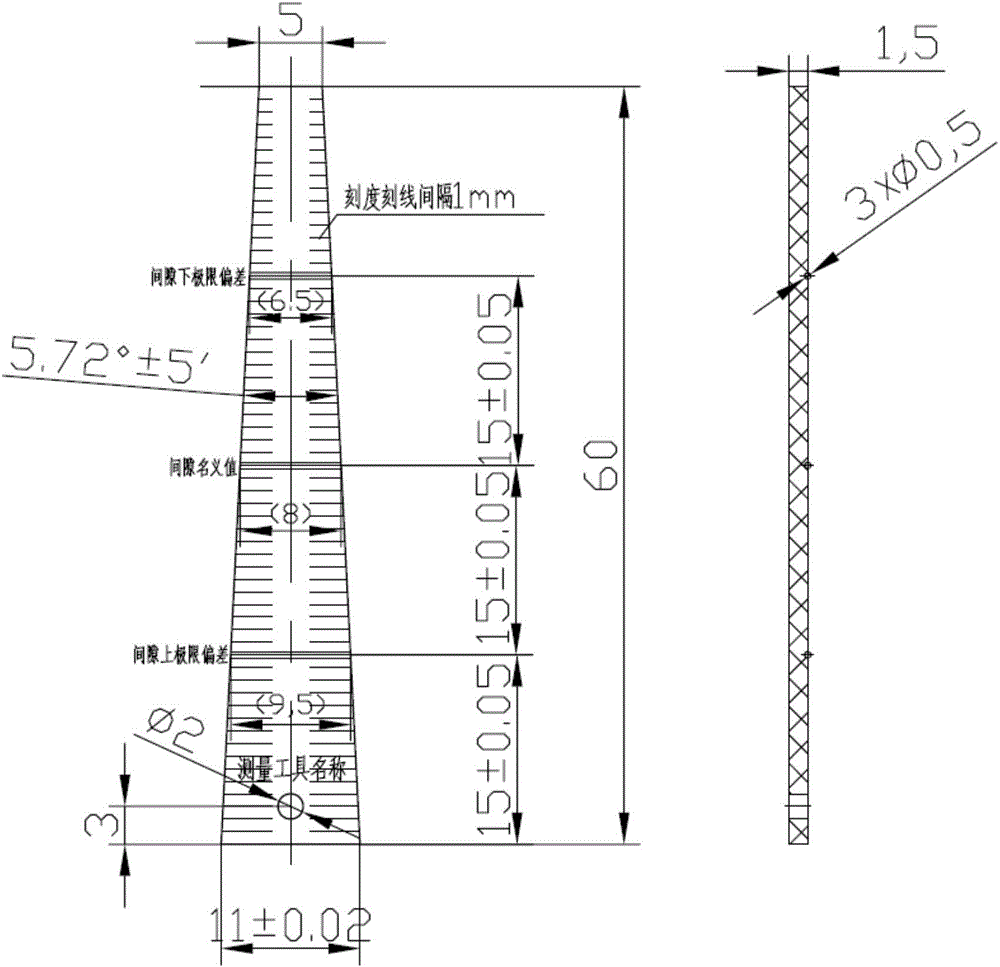

[0027] as attached figure 1 As shown, the gap measuring tool of the present invention is composed of a measuring ruler with a trapezoidal structure with standard scale lines, which is very suitable for gap measurement of the interior and exterior of the cab. The entire gap measurement tool is made of polyurethane material, which can effectively prevent the paint surface from being scratched during measurement. The thickness is preferably 1-2m, more preferably 1.5mm. The shape of the gap measurement tool is designed as an isosceles trapezoidal structure, that is, the gap measurement The tool is preferably an isosceles trapezoidal measuring ruler, the angle between the hypotenuses where ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com