Terahertz optical path calibrator, converging and parallel optical path calibrating device

A technology of terahertz and calibrator, which is applied in the field of optical applications, can solve problems such as potential safety hazards, high laser intensity, and beam attenuation, and achieve the effects of improving optical path calibration accuracy, wide beam practicability, and reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

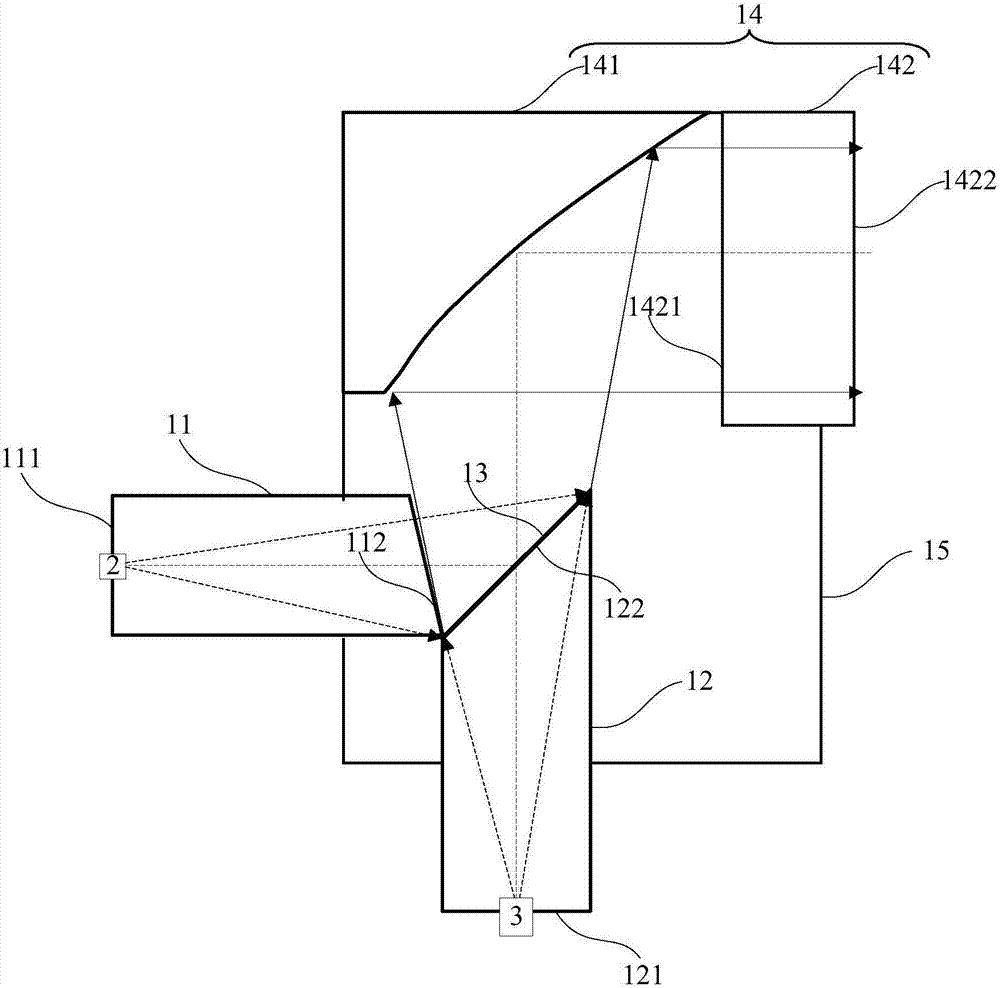

[0057] see figure 1 , the present invention provides a terahertz optical path calibrator 1, the terahertz optical path calibrator 1 includes: a terahertz optical path tube 11, the terahertz optical path tube 11 includes a terahertz light source placement port 111 and a light output port 112; a visible light path Tube 12, the visible light tube 12 is vertically placed with the terahertz tube 11, including a visible light source placement port 121 and a light output port 122, the visible light tube output port 122 is in phase with the terahertz tube light output port 112 Adjacent, and the end face of the light output port 122 of the visible light line tube is an inclined surface, and the inclined surface faces the light output port 112 of the terahertz light line tube; the axial centerline of the visible light line tube 12 and the terahertz light line tube The axial centerlines of 11 intersect, and the intersection point of the two is located at the light exit port 122 of the vi...

Embodiment 2

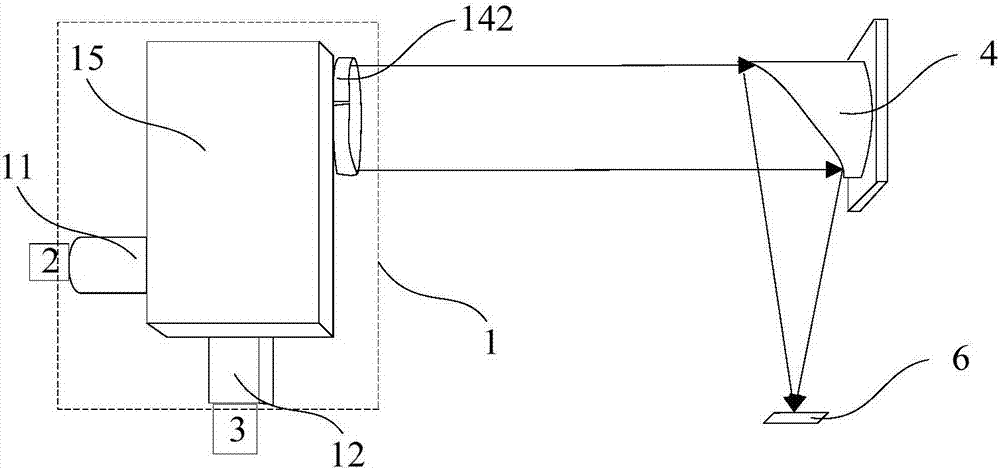

[0070] see figure 2 , the present invention also provides a converging optical path calibrating device, the converging optical path calibrating device includes the terahertz optical path calibrator 1 as described in Embodiment 1; the first reflective or transmissive optical element 4, the first reflective or transmissive The optical element 4 is located on the side of the light beam exporting port 1422 of the coupling light deriving optical path module 14, and is located on the optical path of the parallel light beam exported by the coupling light deriving optical path module 14, and is suitable for exporting the coupling light deriving optical path module 14 The parallel beams are converted into converging beams.

[0071] As an example, the structural parameters of the first reflective or transmissive optical element 4 may be the same as those of the coupling beam deriving optical path module 14 .

[0072] As an example, the first reflective or transmissive optical element ...

Embodiment 3

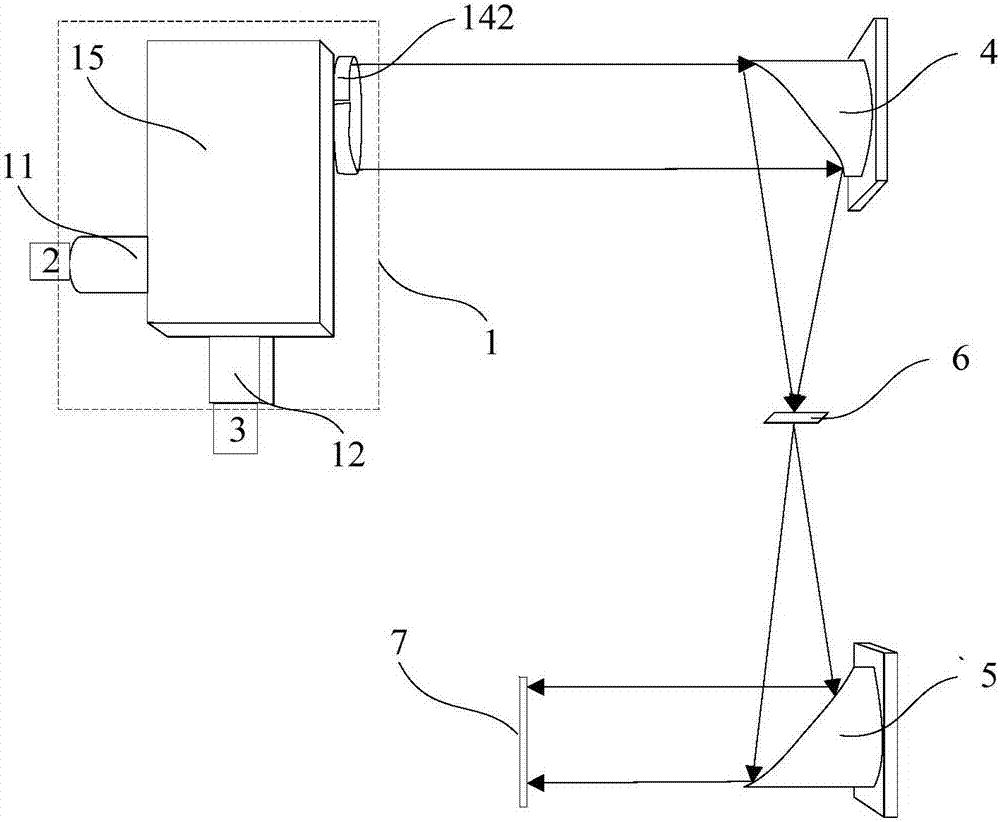

[0077] see image 3 , the present invention also provides a parallel optical path calibration device, the parallel optical path calibration device includes the converging optical path calibration device described in Embodiment 2; the second reflective or transmissive optical element 5, the second reflective or transmissive optical element 5 Located on the side of the first reflective or transmissive optical element 4, and on the optical path of the converging light beam converted by the first reflective or transmissive optical element 4, suitable for converting the converging light beam converted by the first reflective or transmissive optical element 4 The light beam is converted into a parallel beam.

[0078] As an example, the structural parameters of the second reflective or transmissive optical element 5 may be the same as those of the coupling beam deriving optical path module 14 and the first reflective or transmissive optical element 4 .

[0079] As an example, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com