A method for measuring the solid content of catalytic cracking oil slurry

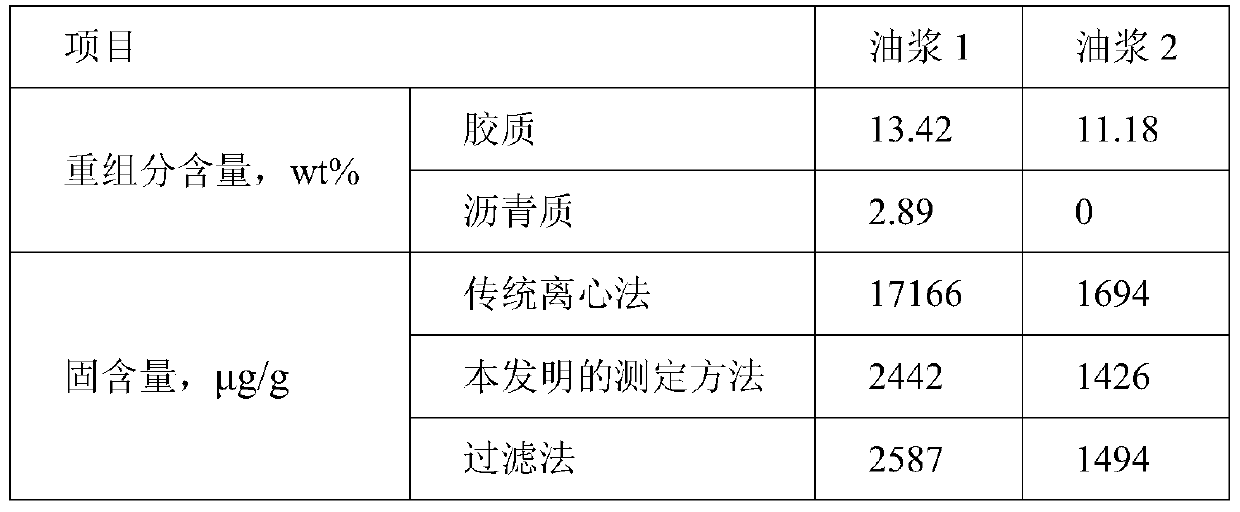

A technology for catalytic cracking oil slurry and a determination method, which is applied in the field of determination of the solid content of catalytic cracking oil slurry, can solve the problems of high price, large error, and difficulty in achieving centrifugation, and achieves time saving, stable, accurate and fast determination results. measured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with embodiment the present invention is further described.

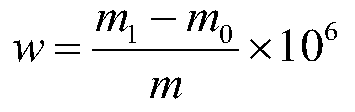

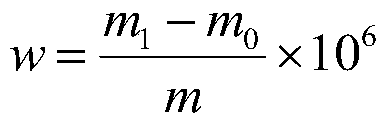

[0032] A method for determining the solid content of catalytic cracking oil slurry, comprising the steps of:

[0033] (1) select the plastic centrifuge tube of 50mL for use, and weigh the centrifuge tube;

[0034] (2) Pretreat the catalytically cracked oil slurry, preheat the catalytically cracked oil slurry to 60°C, and stir at a constant temperature for 15 minutes, so that the solids in the oil slurry are evenly distributed in the oil slurry, and avoid particle settling. Particle distribution is uneven.

[0035] (3) Take 10g of the oil slurry treated in step (2) and add it to the weighed centrifuge tube, and add diluent toluene to dilute, the amount of toluene added is the sum of the amount of toluene and oil slurry to reach the 40mL scale line, then stir to make it evenly mixed, put the centrifuge tube into the centrifuge for centrifugation operation, the centrifugation operation con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com