Test point quantitative selection method and device in testing design

A technology for selecting devices and test points, applied in the field of test optimization design, can solve the problems of test repetition, waste, low coverage of failure modes, etc., and achieve the effect of reducing test design cost and improving detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

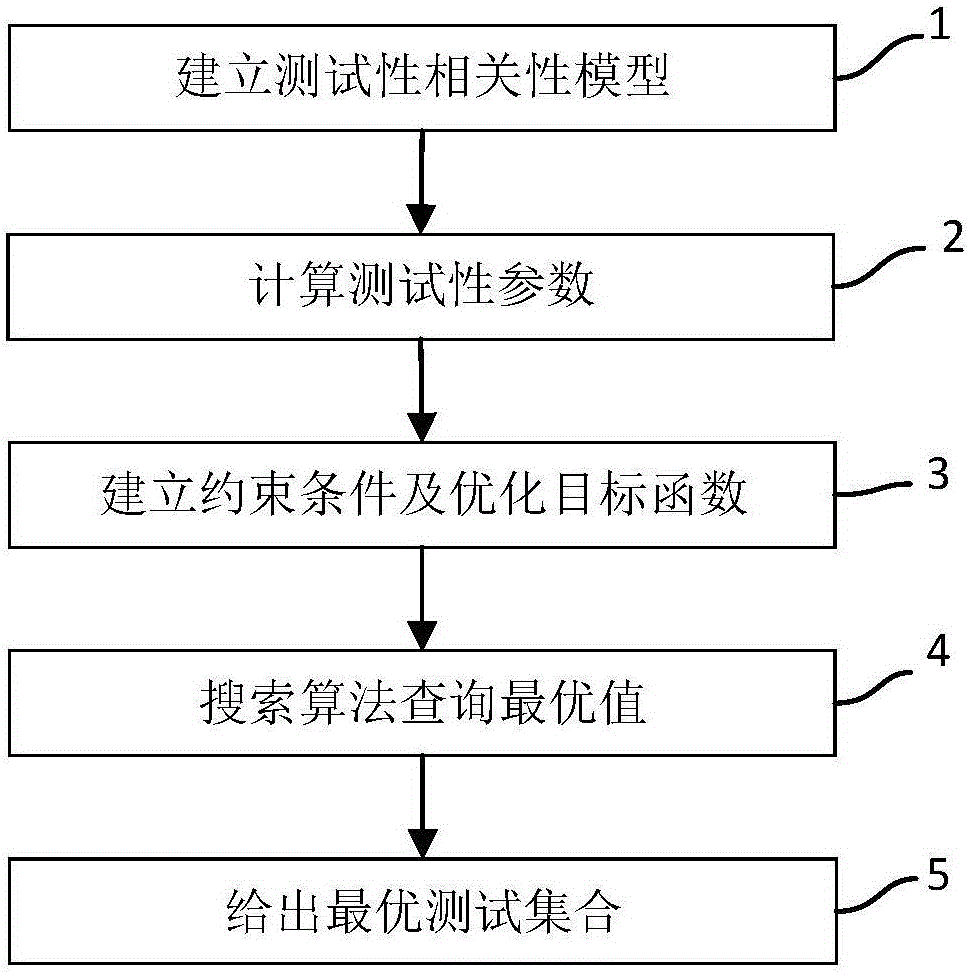

[0056] A method for quantitatively selecting test points in testable design, the process is as follows figure 1 shown, including the following steps:

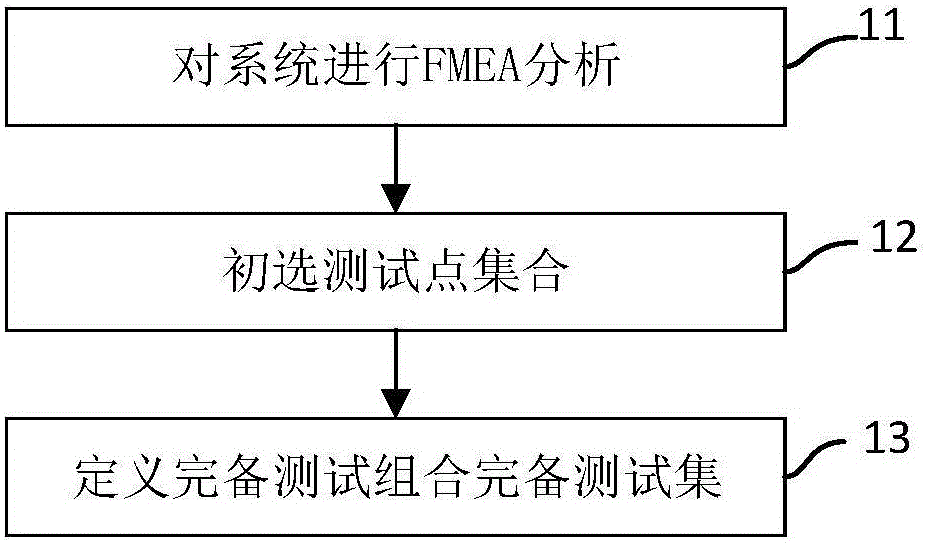

[0057] Step 1: Build a correlation matrix between failure modes and test points:

[0058]

[0059] Among them, the candidate test set is T={t i}(i=1,2,3...n),t 1 , t 2 ...t n is an alternative test point;

[0060] Fault set is F={f i}(i=1,2,3...m), f 1 , f 2 … m Is the system or equipment failure mode;

[0061] ft mn Indicates that the nth test point detects the mth failure mode.

[0062] The correlation matrix FT represents the correlation between the test point and the failure mode. From this matrix, it can be easily distinguished whether a certain failure mode is related to the selected test point or test set. At the same time, the form of the matrix is more conducive to testabilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com