Attitude control thruster layout optimization method for combined spacecraft

A thruster layout and combined spacecraft technology, which is applied in the field of satellite attitude control, can solve the problems of thruster layout optimization, etc., and achieve the effect of prolonging the working life of the orbit and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0149] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

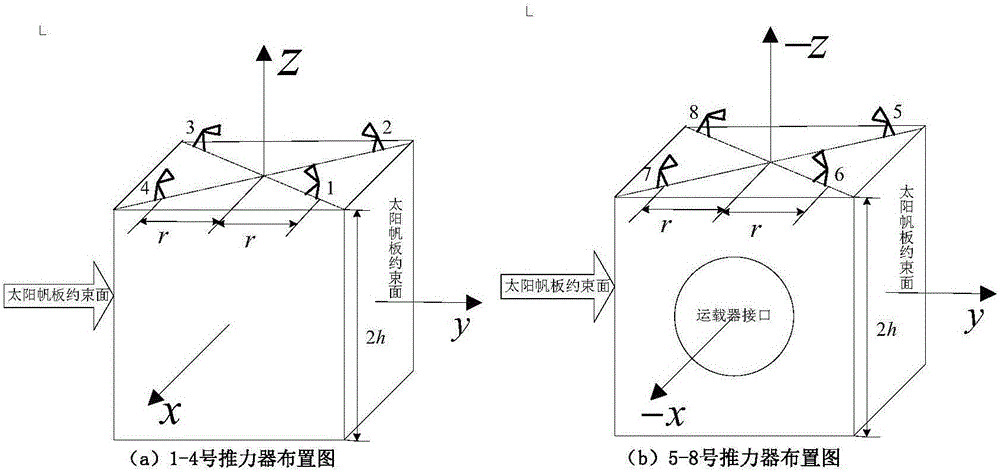

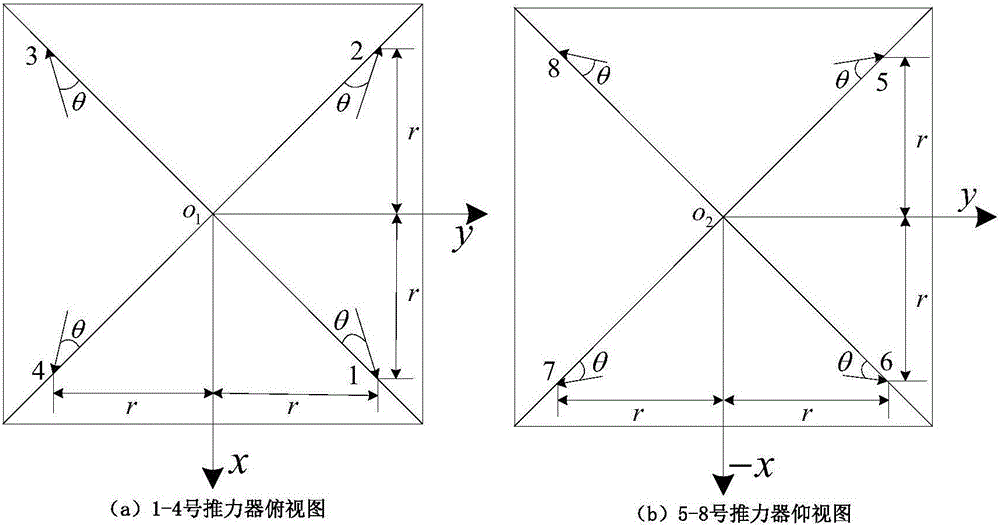

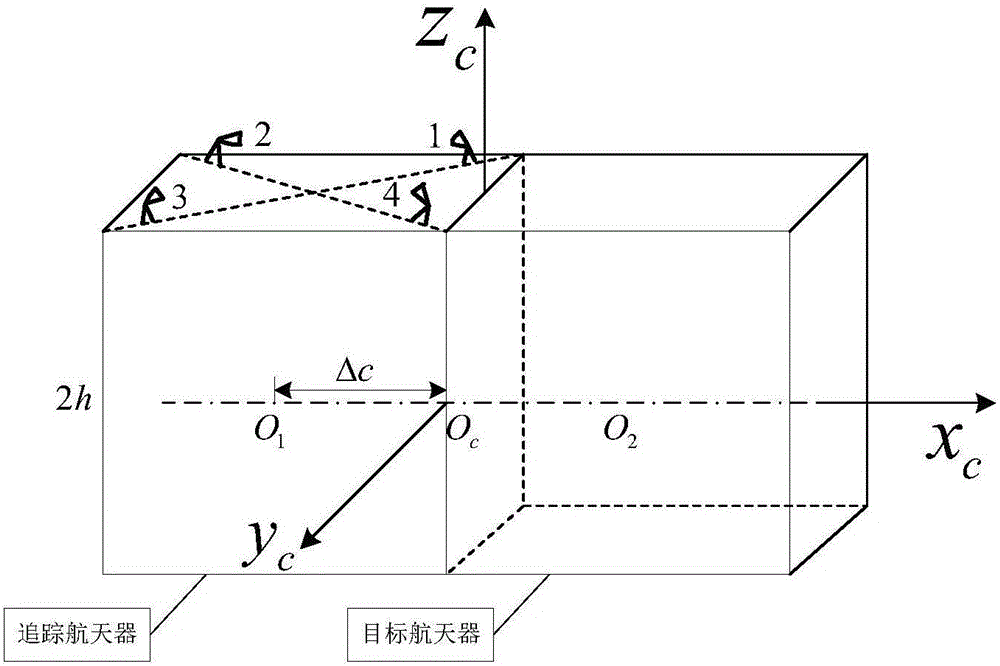

[0150] A method for optimizing the layout of a combined spacecraft attitude control thruster according to the present invention takes a tracking spacecraft in the shape of a cube (2m×2m×2m) as the research object, which has the same shape as the target satellite it docks with. The tracking spacecraft is configured as figure 1 , figure 2 As shown, the configuration of the combined spacecraft after rendezvous and docking is as follows image 3 shown.

[0151] The rotation mode of the universal joint installed at the joint of the thruster is as follows: Figure 4 , Figure 5 shown. The universal joints are installed on the thrusters 1, 2, 1 and 2 of the combined spacecraft respectively, and the simulation is carried out according to the different rotation modes of the universal joints.

[0152] Its simulation parameters are as follows:

[0153] Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com