A flexible circuit board equipped with type-c interface and manufacturing method thereof

A technology of flexible circuit boards and manufacturing methods, which is applied to printed circuits connected with non-printed electrical components, printed circuits, printed circuits, etc., can solve problems such as long production cycle, complicated production process, and difficult production, and achieve good quality products The effect of high rate, improved efficiency and shortened process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

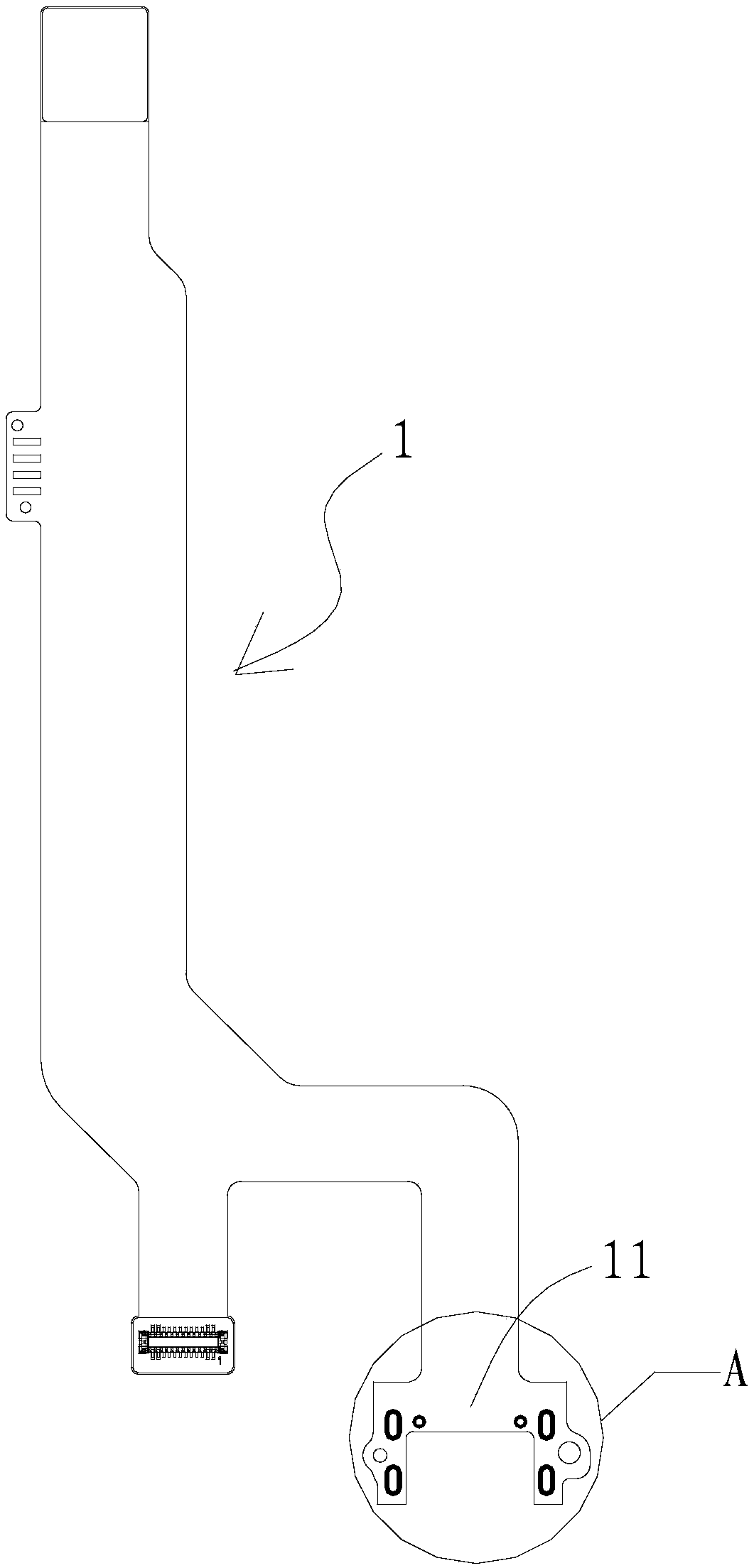

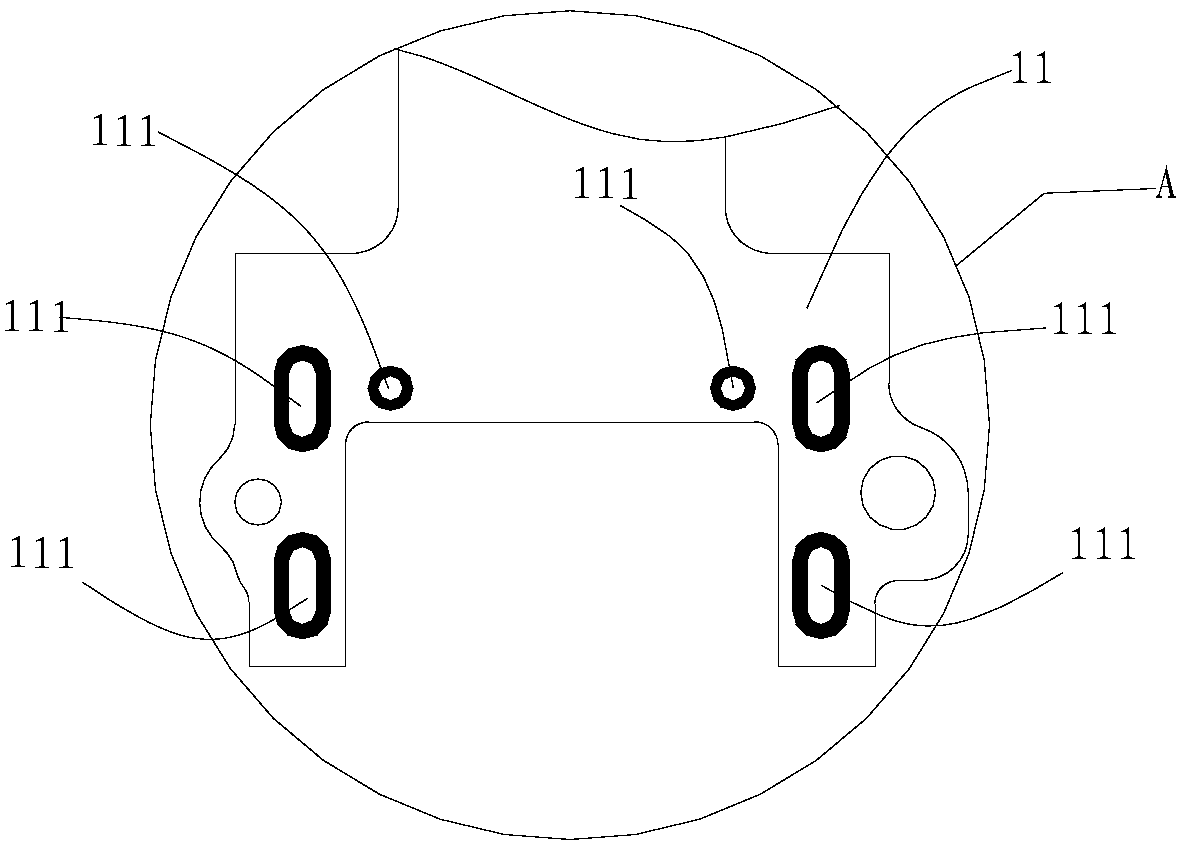

[0026] Such as Figure 1 ~ Figure 5 As shown, the flexible circuit board 100 equipped with a Type-C interface of the present invention includes a flexible circuit board 1 and a reinforcing sheet 2 that are pressed into one body by pure glue 3.

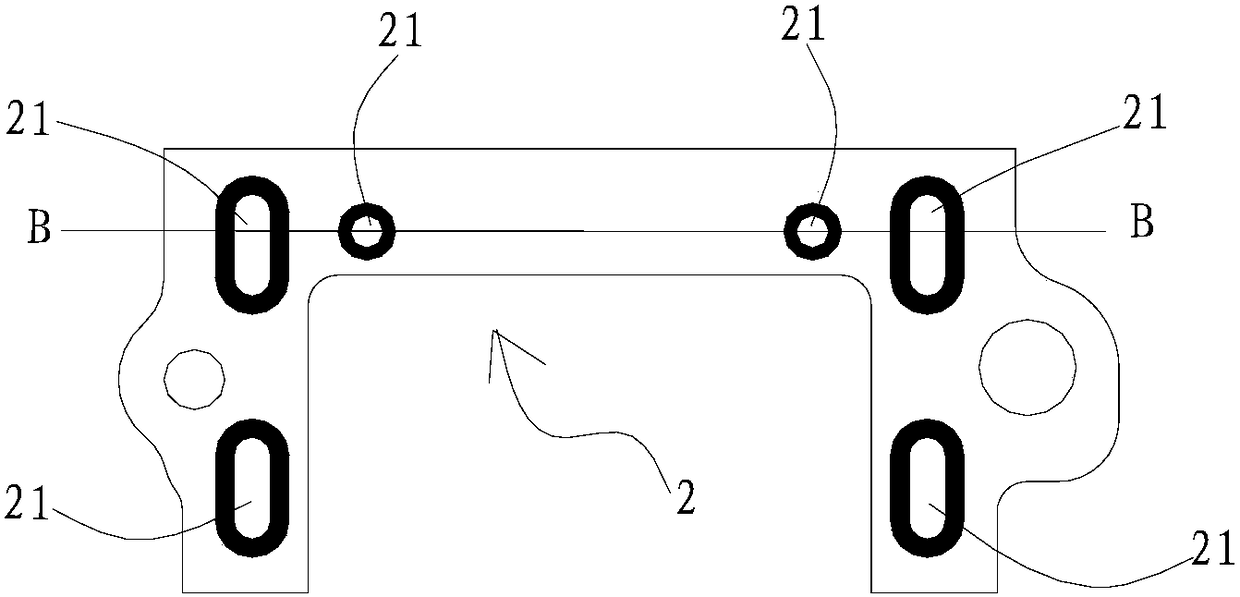

[0027] Such as figure 1 , figure 2 As shown, the flexible circuit board 1 is provided with a Type-C interface area 11, and the Type-C interface area 11 is provided with a metalized first fixing hole through which the fixing pin 91 of the Type-C interface 9 can pass. 111; such as image 3 As shown, the reinforcing sheet 2 is made of FR4 material, and the reinforcing sheet 2 is fitted with the first fixing hole 111, and is provided with a metalized second fixing pin 91 that can accommodate the Type-C interface 9 passing through. The fixing hole 21, a copper ring 22 with a width of 0.2mm-0.5mm is reserved around the second fixing hole 21, and the diameter of the second fixing hole 21 is smaller than that of the first fixing hole 111; Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com