Color-treated base material and base material color treatment method therefor

A color treatment and substrate technology, applied in the direction of metal material coating process, etc., can solve the problems of difficult to present metallic metallic texture, difficult to present multiple colors and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

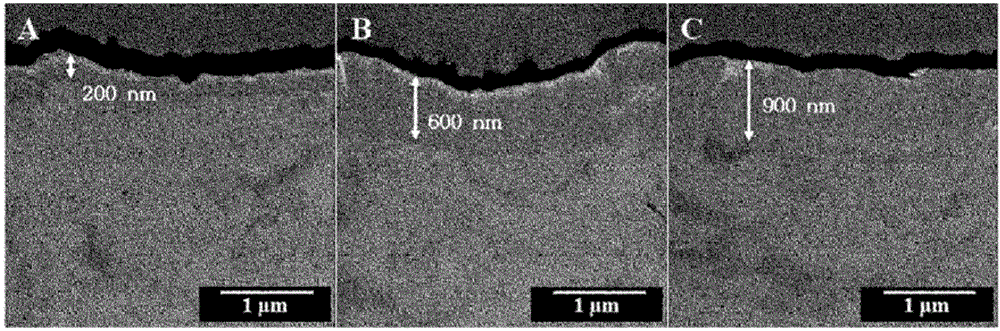

[0136] A test piece (4 cm x 7 cm x 0.4 T) prepared as a substrate containing magnesium was immersed in an alkaline cleaning solution to degrease. After that, a container containing a 100°C, 10% by weight NaOH aqueous solution was placed in a heated reaction container whose surface was burnt to 150°C, so that the temperature at the bottom of the container was adjusted to be close to 150°C by the heat rays that heated the reaction container. The degreased test piece is soaked in the container in such a way that the horizontal surface of the test piece is in contact with the bottom of the container, and the immersion is carried out for a total of 80 minutes. After the test piece is rinsed with distilled water, it is dried in a drying oven to produce a color-developed test piece. piece.

[0137] When the test piece was observed with naked eyes, it was confirmed that the surface of the test piece showed colors such as red, yellow, and green sequentially like a rainbow.

Embodiment 2

[0139] A color-developed test piece was produced by the same method as in Example 1 above. Thereafter, matte clear coating was performed on the test piece, thereby producing a color-developing-treated test piece formed with a matte surface coating layer. At this time, the thickness of the applied matte transparent coating agent is about 5 μm or less.

Embodiment 3

[0141]A color-developed test piece was produced by the same method as in Example 1 above. Thereafter, glossy / matte transparent coating was performed on the test piece, thereby manufacturing a color-developing-treated test piece formed with a glossy / matte surface coating layer. At this time, the thickness of the coated glossy / matte transparent coating agent is about 5 μm or less.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com