Mixed ensilage and preparation method thereof

A technology of mixing silage and feed, which is applied in the field of silage, can solve the problems that the growth of alfalfa cannot achieve the expected effect, and achieve the effect of improving the current situation of silage, great practical value and economic significance, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

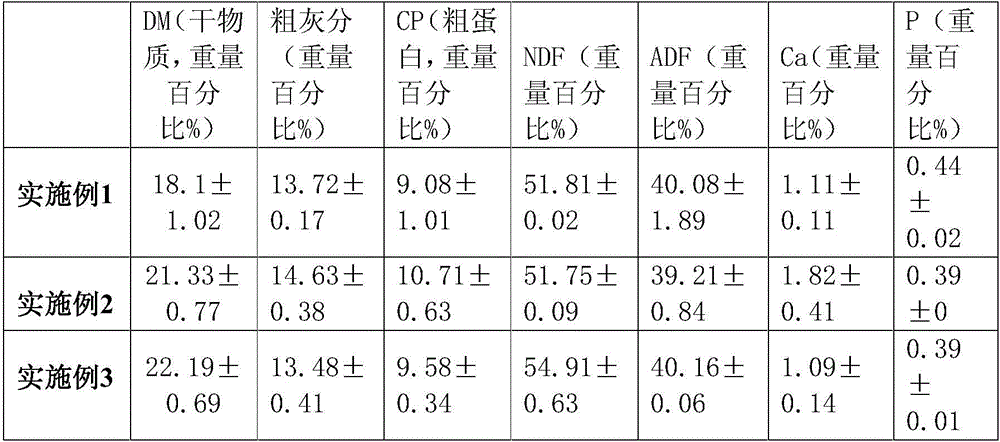

Embodiment 1

[0026] A preparation method of mixed silage, carried out as follows:

[0027] (1) Harvest fresh grass and cut into sections:

[0028] Harvest and harvest the fresh pastures of duckweed and ramie from 5cm above the ground on sunny days. %, and then cut it into sections according to the length of each section of 3cm to 5cm;

[0029] (2) Mix and knead:

[0030] Mix according to the weight percentage of 70% of the fresh pasture grass of Dactylis chinensis and 30% of the fresh pasture grass of ramie, and use a kneading machine to knead the fresh pasture grass until the length of each section is 1.5cm, and mix evenly;

[0031] (3) Fill the above-mentioned mixed herbage into the silage pond layer by layer, compact it with a tractor layer by layer and seal it, and manually step on the places that cannot be pressed around the silage pond and the four corners, and each layer is 17cm to 18cm thick. After the tank is full, cover it with a plastic film, press it tightly with heavy objec...

Embodiment 2

[0033] A preparation method of mixed silage, carried out as follows:

[0034] (1) Harvest fresh grass and cut into sections:

[0035] Harvest the fresh pastures of duckweed, ramie and Chuanzhong goose grass from 5cm above the ground on sunny days, and let them dry for about 8 hours to 12 hours. Dry the fresh grasses until the water content is 60% to 65%, and then press the length of each section of 3cm to 5cm. cut it into pieces;

[0036] (2) Mix and knead:

[0037] Mix according to the percentage by weight of 65% of the fresh pasture grass of Dactylis chinensis, 27% of the fresh pasture grass of ramie, and 8% of the fresh pasture grass of Chuanzhong Goose View Grass, and knead the fresh pasture grass until the length of each section is 1cm~2cm with a kneading machine, and mix evenly;

[0038] (3) Fill the above-mentioned mixed herbage into the silage pond layer by layer, and seal it after compacting layer by layer with a tractor. The places around the silage pond and the fo...

Embodiment 3

[0040] A preparation method of mixed silage, carried out as follows:

[0041] (1) Harvest fresh grass and cut into sections:

[0042] Harvest the fresh forages of Dactylis chinensis and Ramie from the place 5cm above the ground in sunny days, air them in the air for about 8-12 hours, and dry the fresh forages until the water content is 70%-75%, and then cut them into sections according to the length of each section of 3cm-5cm;

[0043] (2) Mix and knead:

[0044] Mix according to the weight percent of 60% of the fresh pasture grass of Dactylis chinensis and 40% of the fresh pasture grass of ramie, and use a kneading machine to knead the fresh pasture grass until the length of each section is 1.0cm, and mix evenly;

[0045] (3) Fill the above-mentioned mixed herbage into the silage pond layer by layer, compact it layer by layer with a tractor, and then seal it. The places around the silage pond and the four corners that cannot be pressed are manually stepped on, and each layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com