A robot for cleaning and detecting insulators of high-voltage transmission lines

A technology for high-voltage transmission lines and insulators, applied to overhead line/cable equipment, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problem of inability to apply overhang or single-string insulator strings, difficult to adjust the applied cleaning force, clamping force Can not be too large and other problems, to achieve the effect of compact structure, stable crawling, and increased adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

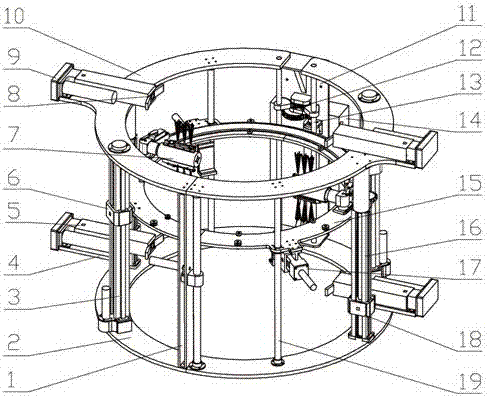

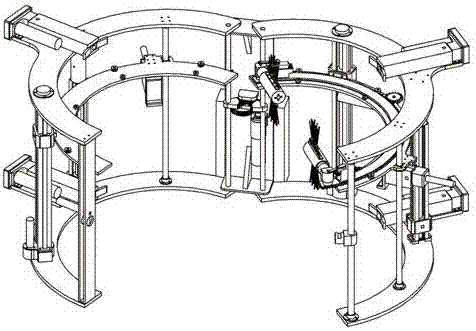

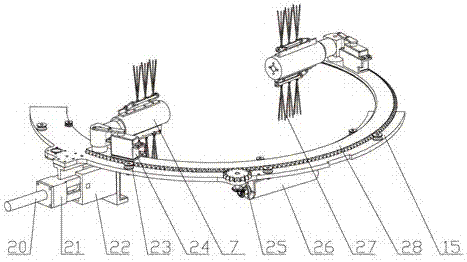

[0036] Such as figure 1As shown, the high-voltage transmission line insulator cleaning and detection robot includes ring frame structures on the left and right sides. The ring frame can rotate along the rotation axis 13 at one end, and the ring frames on both sides can be locked by the locking mechanism when closed; The annular frames each comprise three layers of supports, which are respectively an upper support 10, a middle support 15, and a lower support 1; the upper support 10 and the lower support 1 are consolidated by a number of cleaning layer lifting mechanisms, jaw layer lifting mechanisms and auxiliary supports 19, The middle bracket 15 can slide up and down between the upper bracket 10 and the lower bracket 1 along the cleaning layer lifting mechanism; the upper bracket 10 is equipped with an upper jaw 9 that can clamp the steel cap of the insulator; The lower jaw 5 is installed; the middle bracket 15 is equipped with a cleaning device for cleaning the insulator and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com