Universal pure-electric bus underframe structure

A pure electric bus, general-purpose technology, applied to the substructure, electric power unit, power unit, etc., can solve the problems of long bus body structure design cycle, rising production costs, design and development costs, etc. Quantification, the effect of increasing the strength and stiffness of the car body and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

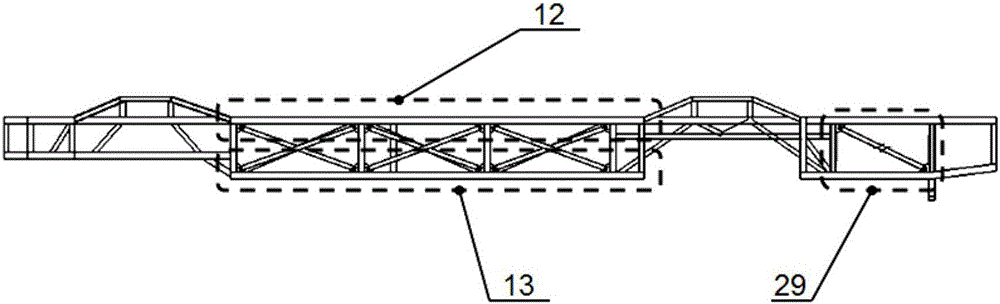

[0034] In order to make this structural scheme clearer, this paper uses a 6.84-meter fully-loaded pure electric mid-bus chassis structure as a specific description:

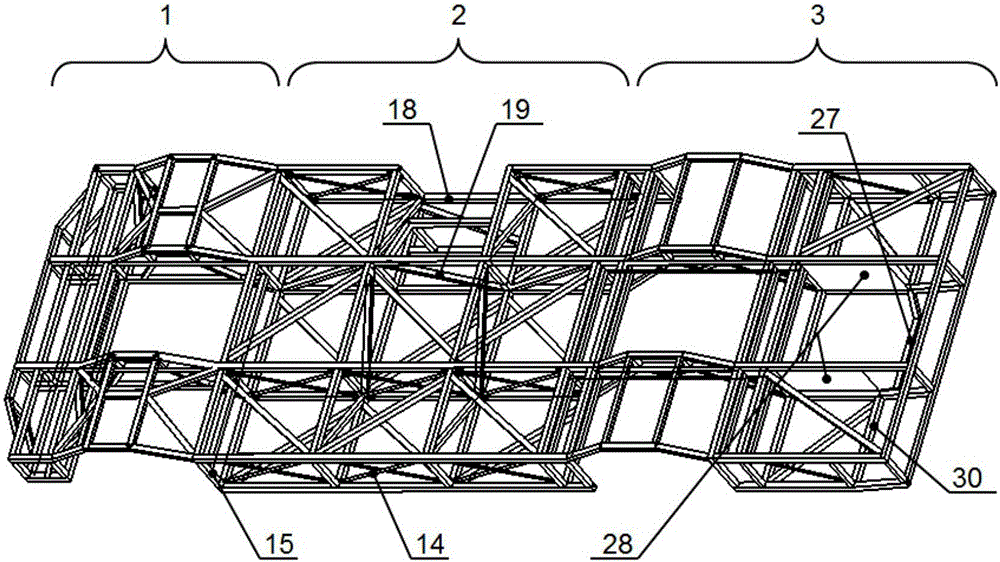

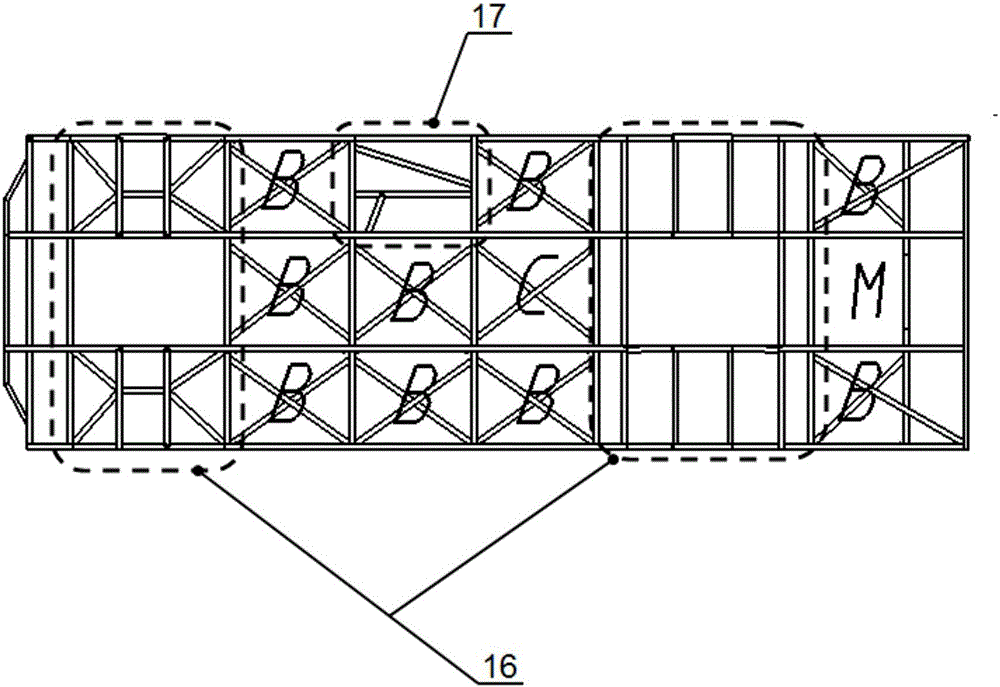

[0035] A general-purpose pure electric passenger car underframe structure, the underframe is a truss structure welded by rectangular steel pipes, which includes a front section 1 of the underframe, a middle section 2 of the underframe, and a rear section 3 of the underframe connected in sequence along the front and rear directions.

[0036] The underframe front section 1 includes three horizontal truss structures connected to each other and parallel to the yoz coordinate plane of the vehicle body coordinate system and the front axle.

[0037] The middle section 2 of the chassis is composed of four longitudinal trusses I, II, III, VI4, 5, 6, 7 and four transverse trusses I, II, III, VI8, 9, 10, 11 parallel to the yoz coordinate plane, The distance between adjacent transverse trusses may be between 800-850 mm, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com