Harmless treatment method of drilling mud produced by in-situ leaching uranium exploration

A technology of harmless treatment and mud, applied in sludge treatment, mining wastewater treatment, chemical instruments and methods, etc., can solve the problems of land acquisition and occupation, high climatic conditions, long treatment period, etc., to achieve good economic stability and rationality, the effect of shortening the setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

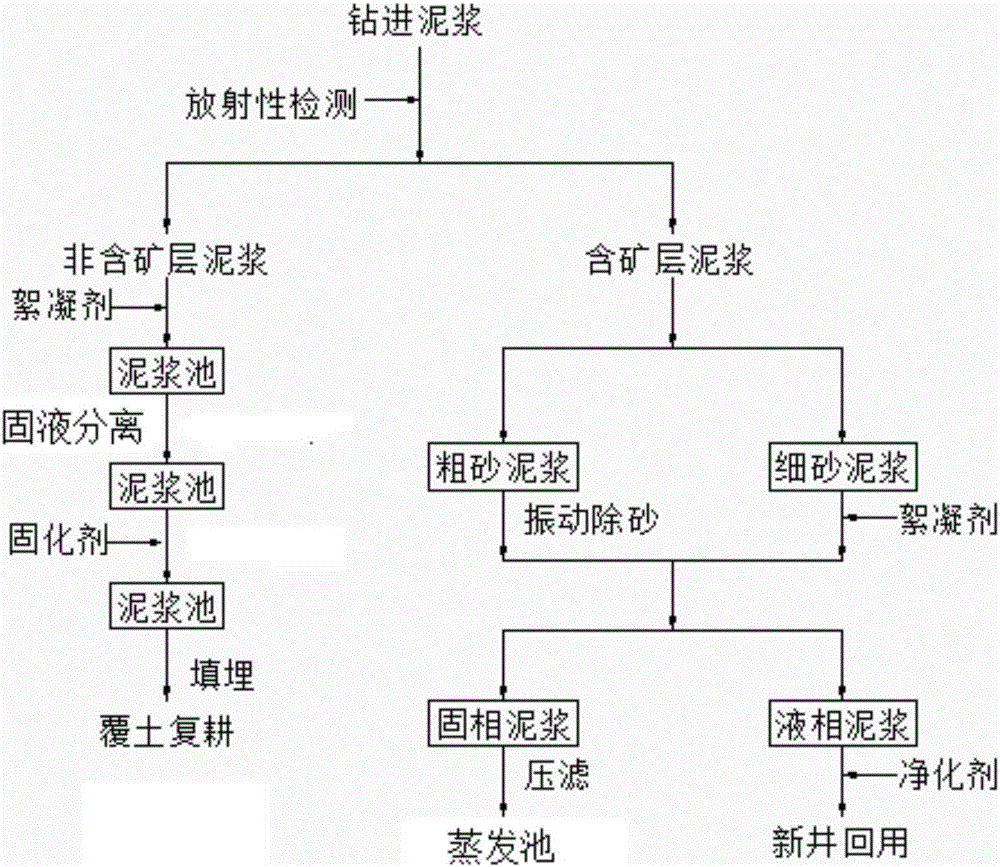

[0035] Such as figure 1 As shown, a method for harmless treatment of in-situ leaching mining uranium drilling mud described in the present invention, the method carries out radioactivity monitoring in the drilling mud process, for non-radioactive mud, i.e. non-ore-bearing layer mud adopts the following method deal with:

[0036] (1) Build a mud pool and a sewage purification pool;

[0037] (2) Pump the non-ore-bearing layer mud into the mud pool with a mud pump, and add flocculant in the mud pool at the same time; the flocculant is ferrous sulfate, and the addition is 20kg / m 3 ;

[0038] (3) In the mud pool, solid-liquid separation is carried out after the mud is stratified into solid and liquid; the supernatant is discharged into the sewage purification tank successively;

[0039] (4) After the solid-liquid separation in step (3), the mud water content in the edge area of the mud pool is directly buried below 5wt%; and the mud water content in the central area of the m...

Embodiment 2

[0043] Such as figure 1 As shown, a method for harmless treatment of in-situ leaching mining uranium drilling mud according to the present invention, the method carries out radioactive monitoring during the drilling mud process, and for radioactive mud, that is, the ore-bearing layer mud is processed by the following method :

[0044] (a) Dividing the ore-bearing layer mud into coarse sand mud and fine sand mud through filtration pretreatment, the particle size of the coarse sand mud is greater than 0.1mm, and the particle size of the fine sand mud is equal to or less than 0.1mm;

[0045] (b) After the coarse sand slurry obtained in step (a) is desandered by a vibration desander, it is divided into solid phase slurry and liquid phase slurry;

[0046] (c) add flocculant to the fine sand mud obtained in step (a) and carry out solid-liquid separation, be divided into solid phase mud and liquid phase mud; Described flocculant is ferrous sulfate, and add-on is 20kg / m 3 ;

[0047...

Embodiment 3

[0050] Such as figure 1 Shown, a method for innocuous treatment of in-situ leaching uranium drilling mud, the method carries out radioactive monitoring in the drilling mud process, for non-radioactive mud, that is, the non-ore-bearing layer mud is processed by the following method:

[0051] (1) Build a mud pool and a sewage purification pool;

[0052] (2) Pump the non-ore-bearing layer mud into the mud pool with a mud pump, and add flocculant in the mud pool at the same time; the flocculant is ferrous sulfate, and the addition is 20kg / m 3 ;

[0053] (3) In the mud pool, solid-liquid separation is carried out after the mud is stratified into solid and liquid; the supernatant is discharged into the sewage purification tank successively;

[0054] (4) After the solid-liquid separation in step (3), the mud water content in the edge area of the mud pool is low and directly buried; while the mud water content in the central area of the mud pool is high, use a curing agent to mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com