A kind of environmentally friendly ecological wood/negative oxygen ion powder blended closed-cell secondary foaming material and preparation method thereof

A technology of negative oxygen ion powder and secondary foaming, which is applied in the field of foaming materials, can solve the problems of poor recycling effect of composite ecological wood, not enough environmental protection, and great harm to human body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A preparation method of an environmentally friendly ecological wood / negative oxygen ion powder blended closed-cell secondary foaming material, comprising the following steps:

[0056] (1) Preparation of negative oxygen ion premixed powder: 100PHR tourmaline powder, 100PHR Wizard R series plastic / rubber additive 1250 mesh, 5PHR chelating titanate coupling agent, and 100PHR clay are blended and stirred for 12 The temperature was controlled to 80°C during the stirring process, and the negative oxygen ion premixed powder was obtained after the stirring was completed;

[0057] (2) Plant fiber pretreatment: Bake the plant fiber in an oven to reduce the water content of the plant fiber to below 2.5%, weigh 20 PHR of the above-mentioned treated plant fiber with a water content below 2.5%, and put it into a high-speed mixer , add 2PHR chelating titanate coupling agent, stir at high speed for 9 minutes and release;

[0058] (3) Mixing with an internal mixer: 25PHR of plant fiber...

Embodiment 2

[0071] The preparation method of the environmentally friendly ecological wood / negative oxygen ion powder blended closed-cell secondary foaming material described in Example 2 is completely consistent with Example 1, and the difference is that the weight ratio of the raw materials used in Example 2 is as follows:

[0072] Chlorine Vinegar Copolymer Resin 100 PHR

[0073] Negative oxygen ion premixed powder 60 PHR;

[0074] Impact Modifier 10 PHR

[0075] Vegetable Fiber 25 PHR

[0076] Smoke suppressant 15 PHR

[0077] Lubricant 1.5 PHR

[0078] Activator 5 PHR

[0079] Environmentally friendly flame retardant 8 PHR

[0080] Heat Stabilizer 6 PHR

[0081] Odorless Crosslinker 1 PHR

[0082] Blowing agent 3.5 PHR

[0083] Deamination agent 2 PHR.

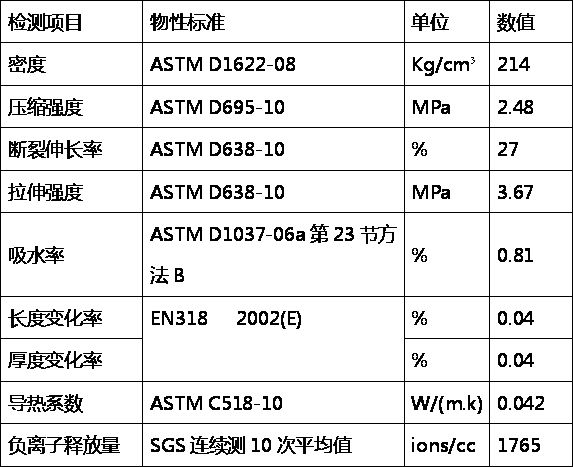

[0084] The physical properties of the environmentally friendly ecological wood / negative oxygen ion powder blended closed-cell secondary foaming material prepared in Example 2 are shown in Table 3 below:

[0085]

[0086] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com