Happy Biomass Gas Stove

A kind of biomass and happy technology, which is applied in the direction of gasification process, manufacture of combustible gas, petroleum industry, etc., can solve the problems of high production equipment requirements, consumption of non-renewable resources, long carbonization time, etc., to reduce labor intensity and increase calorific value , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

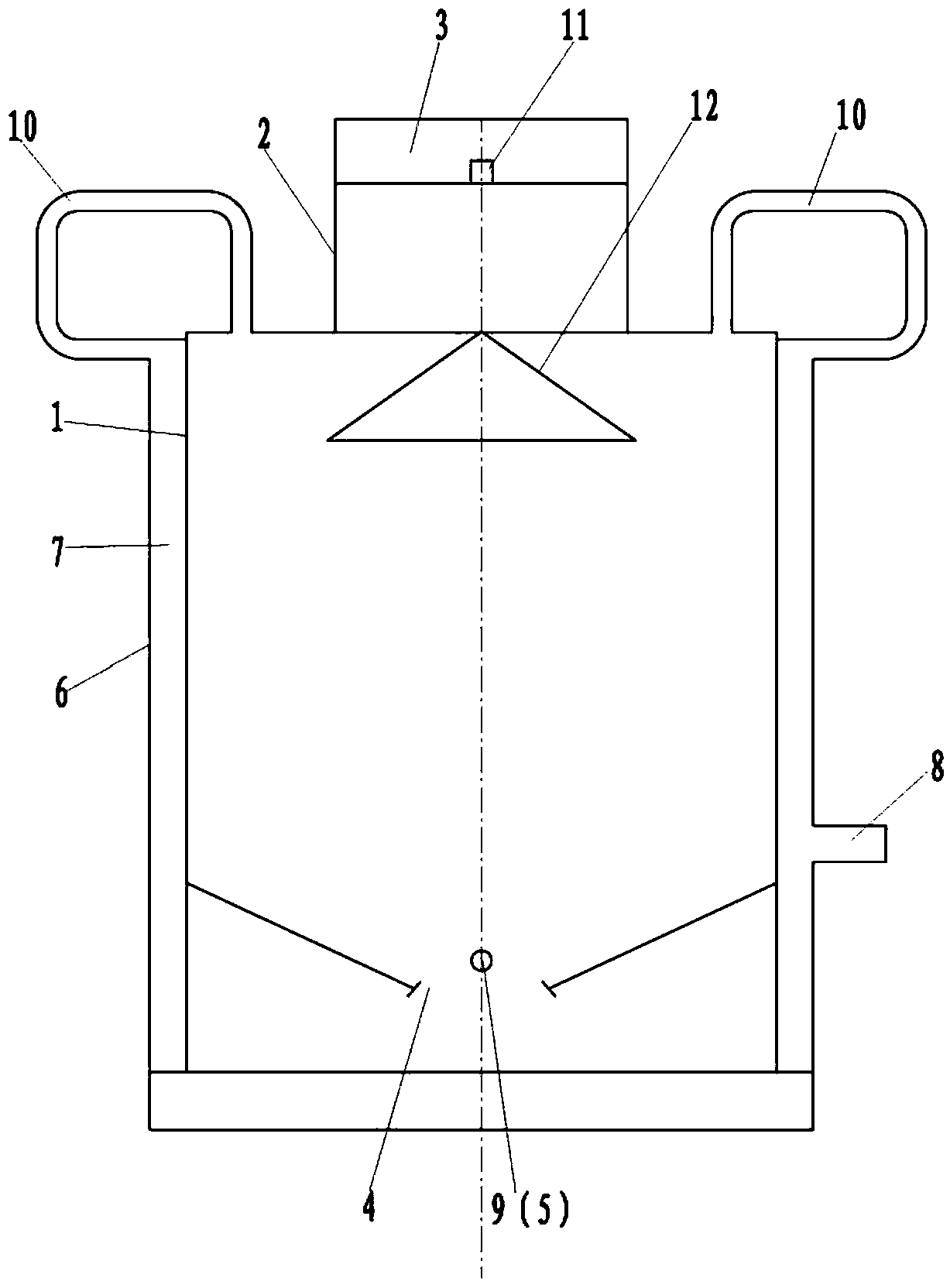

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

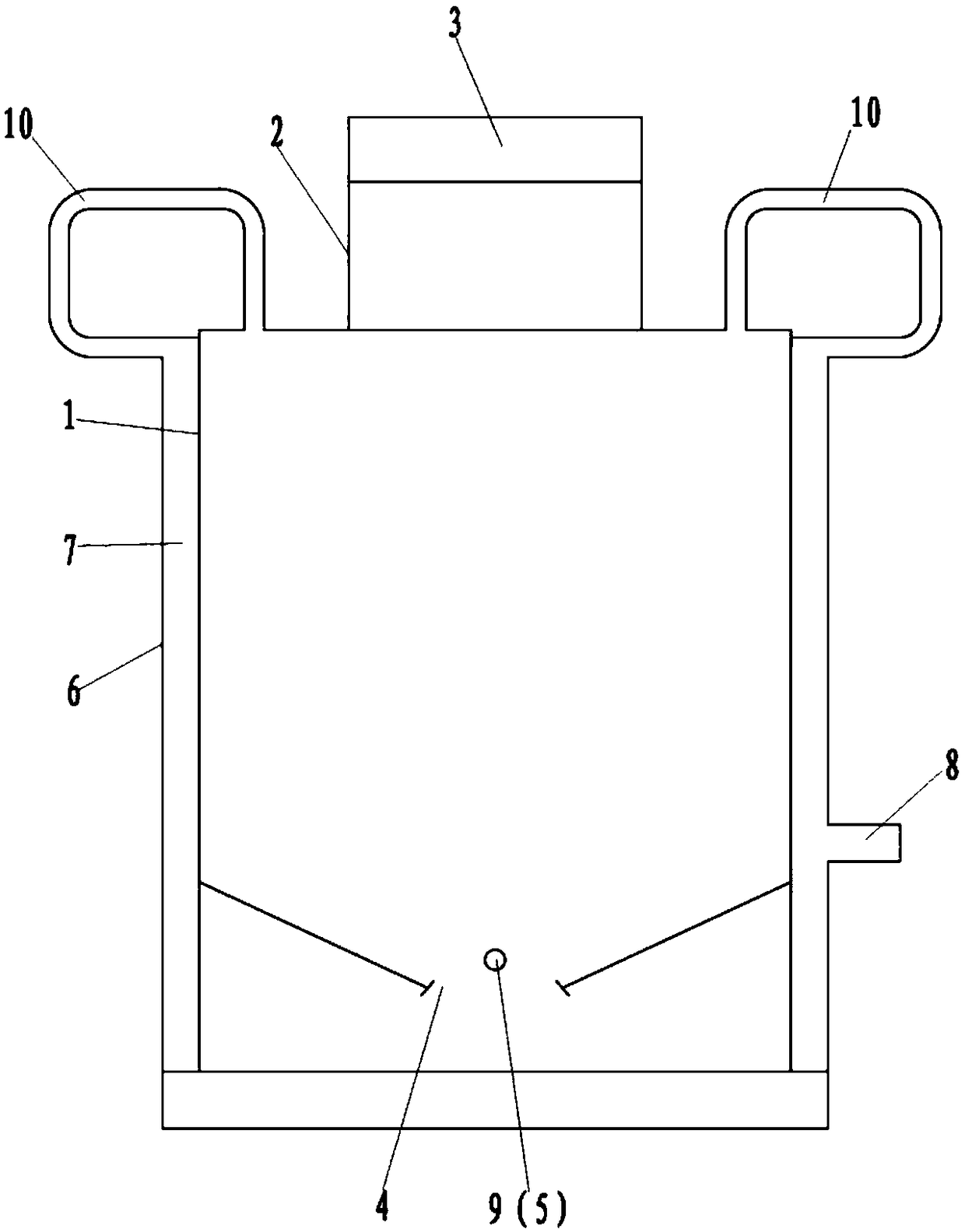

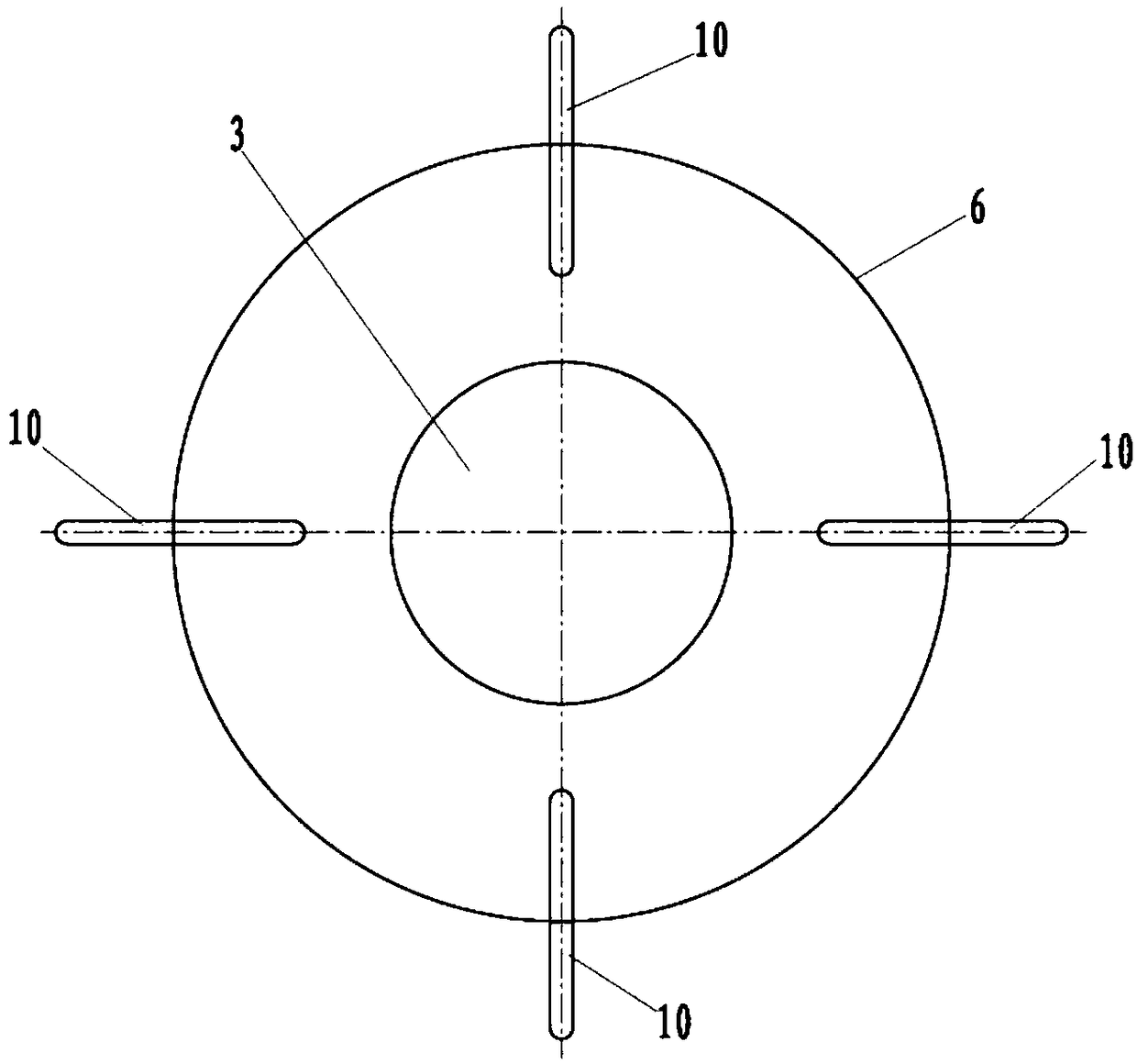

[0032] Such as figure 1 Shown is a schematic structural diagram of Embodiment 1 of the open-ended biomass gas production furnace of the present invention, which includes a cylindrical inner tank 1 made of stainless steel with a high temperature resistance of 1100-1300 °C. The top of the cylindrical liner 1 is provided with a feed port 2, and a detachable upper cover 3 is installed on the feed port 2. The bottom of the cylindrical liner 1 is a conical bottom, and the center of the bottom is provided with a first discharge port 4;

[0033] The lower end of the cylindrical liner 1 is provided with a first ignition port 5, the number of the first ignition ports 5 is generally 1-8, and the circumferential direction is evenly distributed on the cylindrical liner 1, the first ignition port 5 of this embodiment set to 1;

[0034] The outer cylinder 6 is sleeved on the outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com