Integrated laser cladding head

A technology of laser cladding and cladding head, which is applied in the field of integrated laser cladding head, can solve the problems of low efficiency, easy overheating of cladding head, easy blockage of powder spraying channel, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

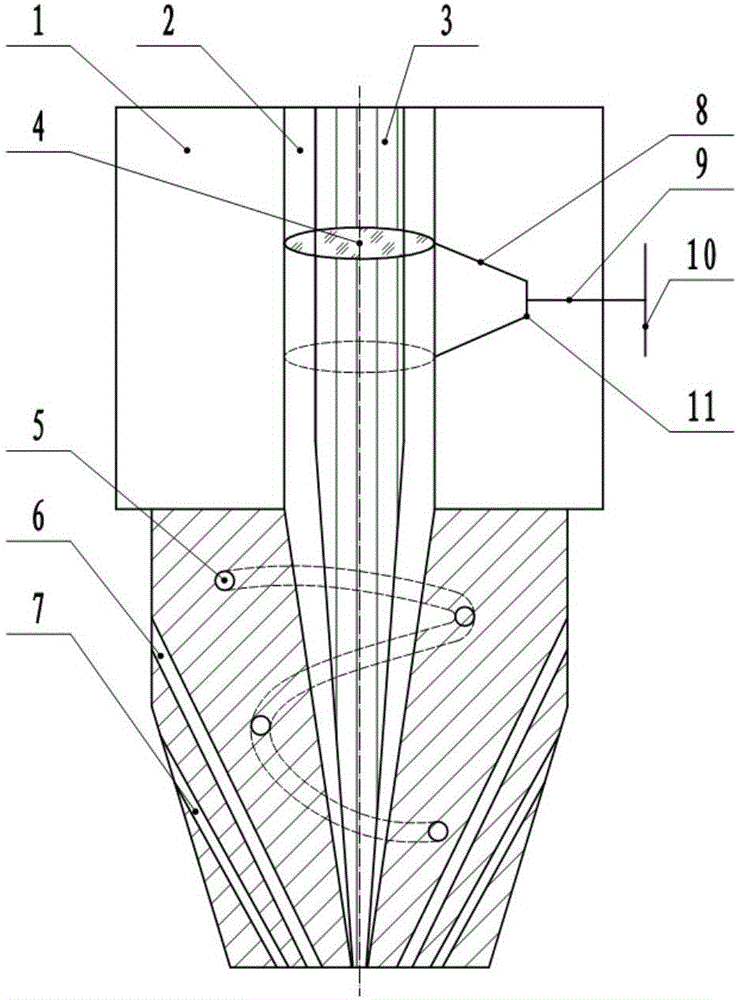

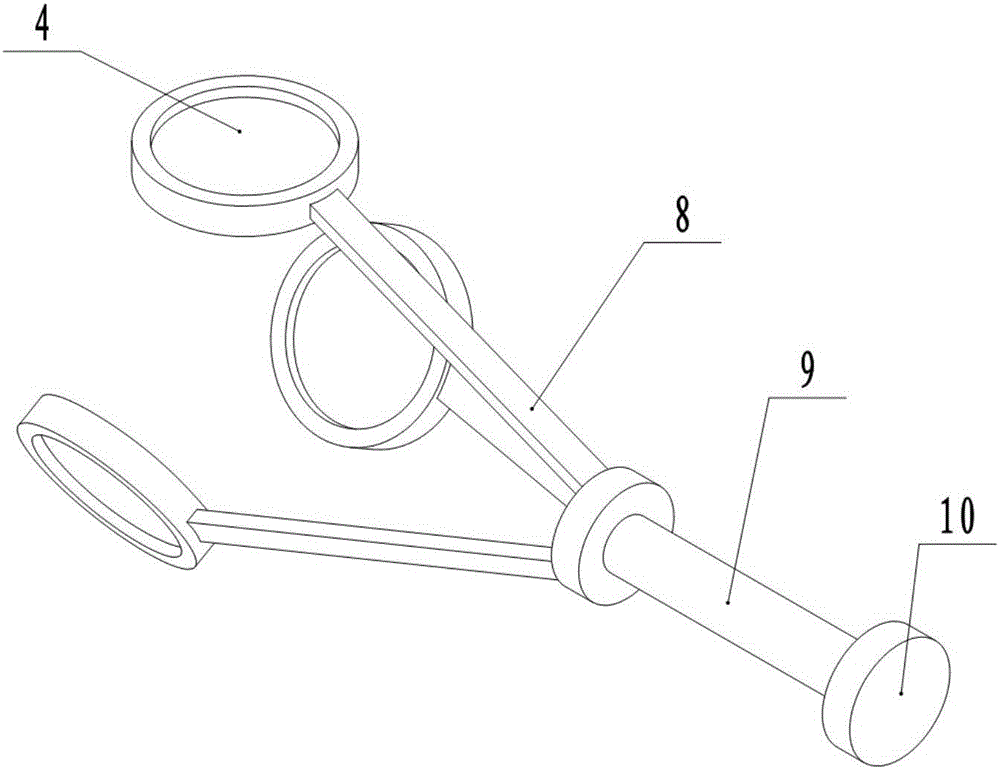

[0013] Such as figure 1 As shown, an integrated laser cladding head includes a cladding head body 1, a laser channel 2 is opened in the center of the cladding head body 1 for the laser 3 to pass through, and a focusing device is provided on the upper part of the cladding head body 1 11. The focusing device 11 includes a conversion frame 8, lenses 4 of three different specifications, a rotating shaft 9 and a knob 10. The lens 4 is embedded in the three rings of the conversion frame 8, and the knob 10 and the conversion frame 8 pass through The rotating shaft 9 is connected, the laser 3 is focused by the lens 4, the lens 4 of different specifications can be switched by turning the knob 10, and the shape of the spot can be changed. The outer side of the laser channel 2 is provided with a cooling water channel 5, and the cooling water channel 5 surrounds in a spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com