Cloth thickness detection device of sewing machine

A thickness detection and sewing machine technology, applied in the field of sewing, can solve the problems of high installation requirements, complex structure, large detection errors, etc., and achieve the effects of high detection accuracy, high detection accuracy and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

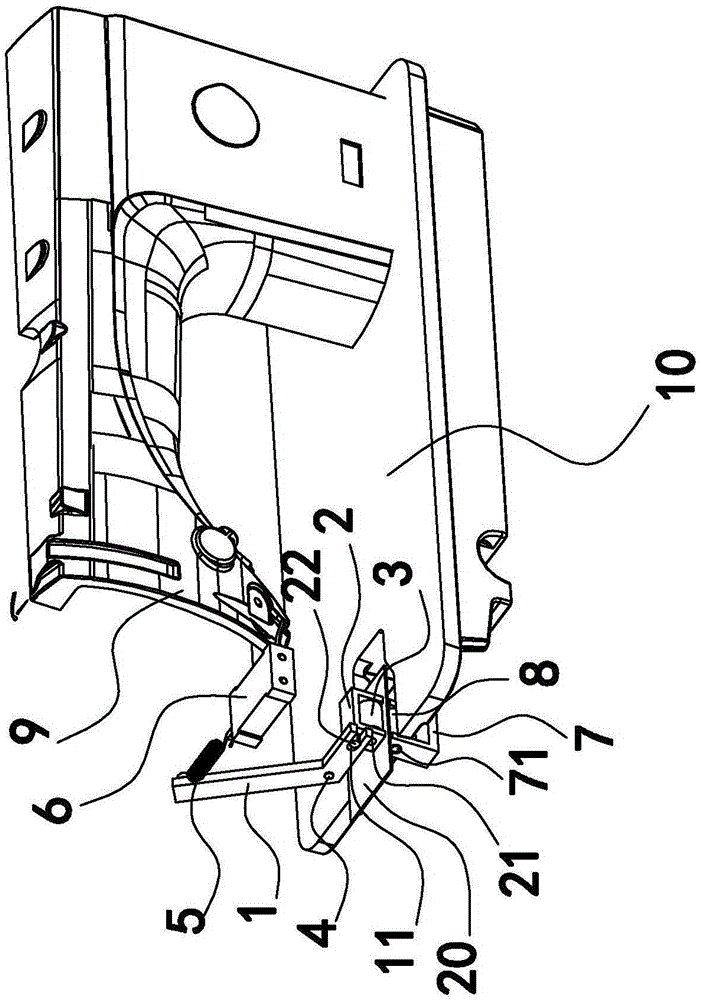

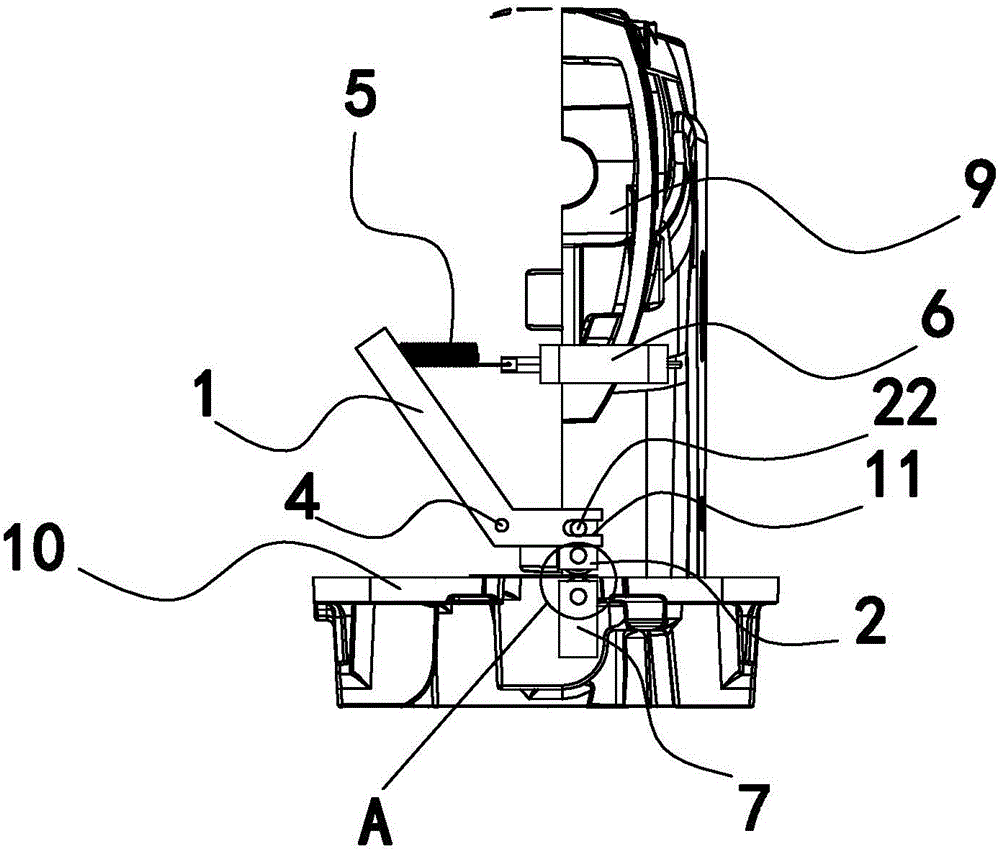

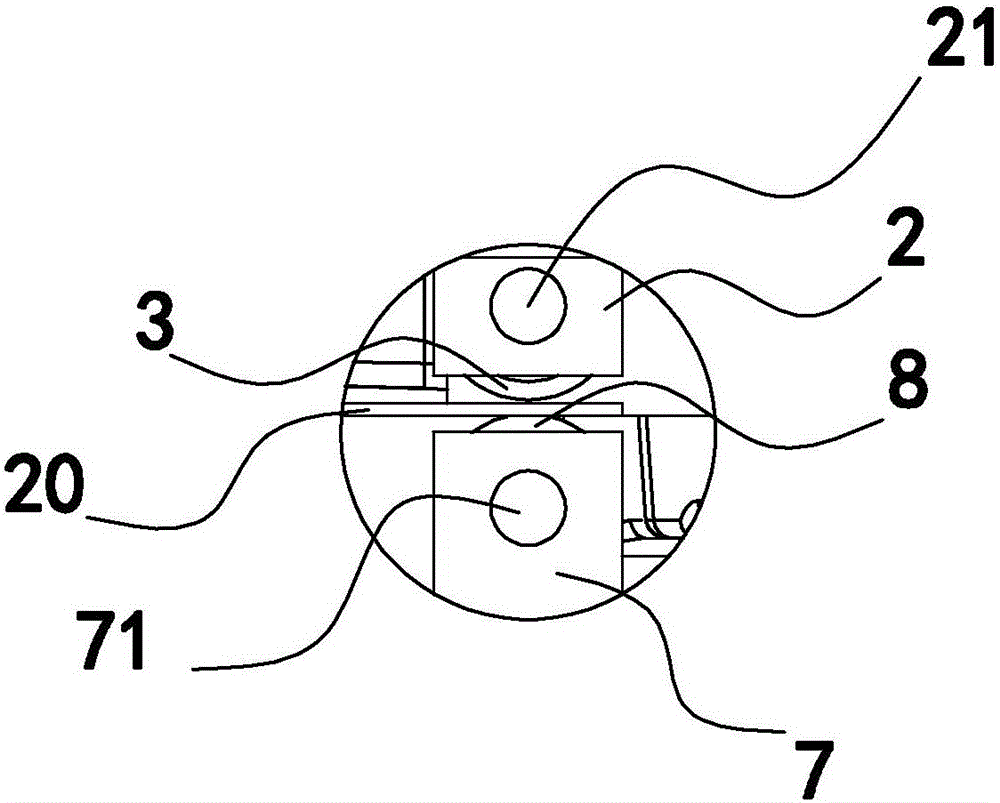

[0023] Such as figure 1 , 2 As shown in and 3, the sewing machine cloth thickness detection device includes a rotating arm 1, a sensor device and an upper pressing wheel mounting seat 2, and an upper pressing wheel 3 is installed on the upper pressing wheel mounting seat 2, and the upper pressing wheel 3 rotates through the rotating shaft-21 Be installed on the upper pressure roller mounting seat 2 and the lower end surface protrudes outside the upper pressure roller mounting seat 2 lower end surface, the middle part of the rotating arm 1 is installed on the sewing machine head 9 by the pin shaft 4 and the rotating arm 1 swings around the pin shaft 4 . The lower end of the swivel arm 1 is provided with a bar-shaped groove 11, and the upper pressing wheel mounting seat 2 is fixedly connected with a transmission shaft 22. The transmission shaft 22 is installed in the bar-shaped groove 11 and can move back and forth therein. The groove width of the bar-shaped groove 11 is It is ...

Embodiment 2

[0033] The structure difference between the present embodiment and the first embodiment is that the sensor device of the present embodiment is an angle sensor, and the angle sensor is fixedly installed on the head of the sewing machine and directly connected with the upper end of the rotating arm. Other structures are the same as those in Embodiment 1, and will not be repeated here. The difference between this embodiment and the method principle of Embodiment 1 is that the angle sensor in this embodiment directly detects the rotation angle of the rotating arm, and then detects the height of the upper pressure roller mounting seat by detecting the rotation angle, which is The measured fabric thickness. Other methods and principles are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0035] The difference between the structure of this embodiment and the first embodiment is that this embodiment cancels the structure of the lower pressure roller, the lower pressure roller mounting seat, the second rotating shaft and the opening on the needle plate in the first embodiment. The wheel is directly located on the needle plate of the sewing machine table, and the lower end surface of the upper pressing wheel is directly connected with the needle plate. Other structures are the same as those in Embodiment 1, and will not be repeated here.

[0036] The difference between this embodiment and the method and principle of Embodiment 1 is that when the cloth enters the detection device through the gap between the lower end surface of the upper pressure roller and the needle plate, since the upper pressure roller can wrap around the upper pressure roller mounting seat 2 The upper rotating shaft-21 rotates, and when the cloth enters, the upper pinch wheel will rotate with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com