Anti-counterfeiting fiber, anti-counterfeiting paper containing anti-counterfeiting fiber and manufacturing methods of anti-counterfeiting fiber and anti-counterfeiting paper

An anti-counterfeiting fiber and anti-counterfeiting paper technology, applied in the field of anti-counterfeiting, can solve the problems of inability to solve the problem of accurate alignment of small-sized color patterns, inability to be used as paper-making anti-counterfeiting fibers, and reduced anti-counterfeiting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

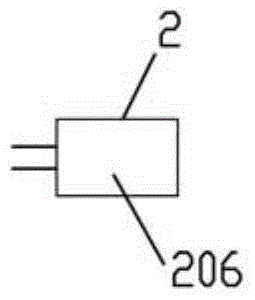

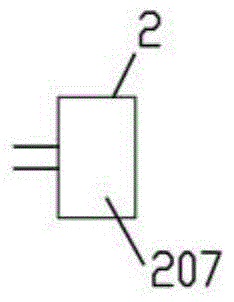

[0079] figure 2 and image 3 Among them, point 2 is yellow under the irradiation of ultraviolet lamp, and connecting line 3 is red under natural white light; or point 2 is red under the irradiation of ultraviolet lamp, and connecting line 3 is blue under the irradiation of ultraviolet lamp.

Embodiment 2

[0081] like figure 2 Among them, point 2 is red, yellow, and green under the irradiation of ultraviolet lamp, and connecting line 3 is blue under the irradiation of ultraviolet lamp;

[0082] Or point 2 is red, yellow and purple under natural white light, and line 3 is blue under natural white light;

[0083] Or the point 2 is red under natural white light, and the two connecting lines 3 are yellow and green respectively under natural white light.

Embodiment 3

[0085] figure 2 Among them, one point 2 or two points 2 or three points 2 are transparent, and / or one connection line 3 or two connection lines 3 are transparent, but the scheme excludes the technical solution of the overall transparency of the anti-counterfeiting fiber.

[0086] image 3 , one dot 2 or two dots 2 or three dots 2 or four dots 2 or five dots 2 or six dots 2 are transparent, and / or one line 3 or two lines 3 are transparent , but the scheme excludes the technical scheme of overall transparency of the anti-counterfeiting fiber.

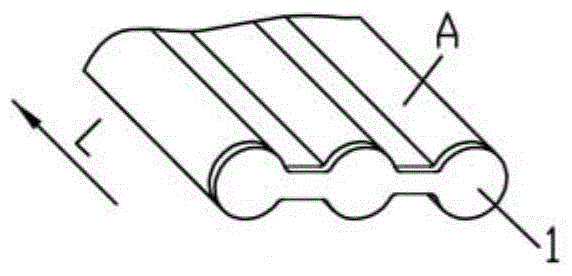

[0087] Although in Figure 1-4 Not shown in , but a preferred solution also includes: the dotted line structure includes two or more connecting lines 3, at least two connecting lines 3 having different lengths and / or different widths.

[0088] Although in Figure 1-4 Not shown in, but the preferred solution also includes: the point line structure includes two or more points 2, at least two points 2 have different geometric shapes (as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com