Prepressing spacer capable of improving windmilling performance of cutter

A performance and preloading technology, applied in the field of road milling equipment and road pick parts, can solve problems such as wear of preloaded gaskets, achieve uniform force, improve free rotation, and facilitate production and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

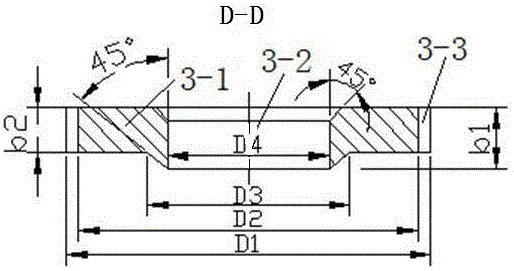

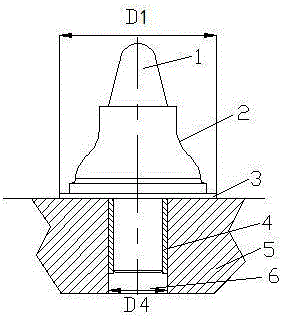

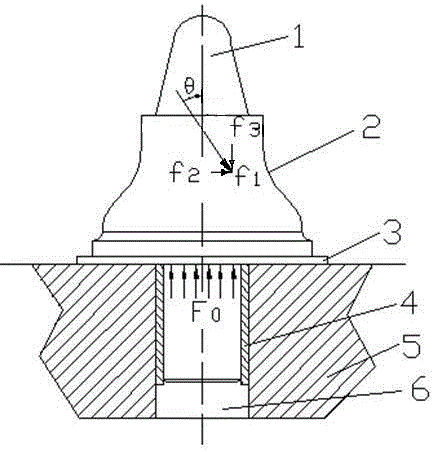

[0017] See figure 1 with figure 2 , The pre-compressed gasket 3 of the present invention is composed of a plate-shaped main body 3-1, the thickness of the plate-shaped main body 3-1 is b2, the geometric center point of the plate-shaped main body 3-1 is provided with a central hole 3-2, the geometric center point It is point O, the central hole 3-2 is a circular through hole, and the diameter of the central hole 3-2 is D4. The peripheral edge of the plate-shaped main body 3-1 is circular, and its peripheral edge diameter is D1. A plurality of notches 3-3 are arranged at the peripheral edge, and the plurality of notches 3-3 are evenly arranged in the circumferential direction, and each notch 3 -3 are all recessed in the direction of the center point O of the plate-shaped body 3-1, so that the opening of the notch 3-3 faces outward, and the thickness of each notch 3-3 is b2. The present invention has 6 notches 3-3 in total, so that the angle β between the center lines of two adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com