Double-ship counter-pulling positioning method of breakwater barrel type component

A positioning method and technology of breakwaters, which are applied in the directions of breakwaters, embankments, jetties, etc., can solve the problems of inability to ensure the uniform force of the double hook, instability, difficulty in achieving safe and fast positioning, etc., so as to improve the positioning accuracy and easy operation. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

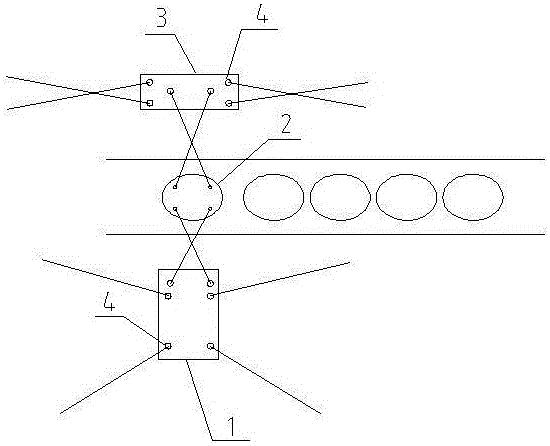

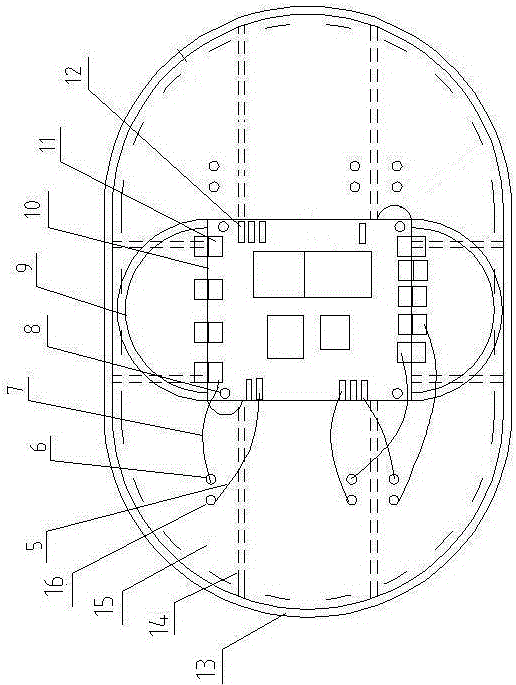

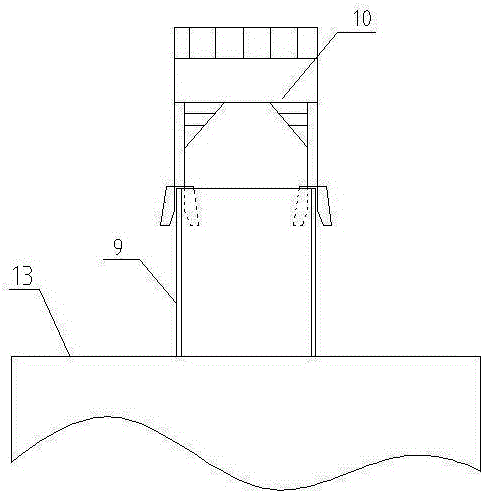

[0017] refer to Figure 1-3 , a double-vessel pull-to-position method for a breakwater bucket-type component, the bucket-type component includes a bottomless and covered oblong barrel body 13 and two anti-wave barrel bodies arranged above the oblong barrel body 13 9. The wave-proof barrel body 9 is arranged along the short axis direction of the oblong barrel body 13, and the oblong barrel body 13 is divided into nine compartments 15 by two vertical and horizontal partition walls 14, and each compartment 15 The top is provided with exhaust holes 16 and drainage holes 6, and the two anti-wave barrels 9 are equipped with an operating platform 10, and the four corners of the operating platform 10 are equipped with GPS data collecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com