A Sandless Vacuum Preloading Soft Soil Foundation Reinforcement Method

A soft soil foundation and vacuum technology, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of reducing the effect of vacuum preloading on soft soil foundation, the loss of vacuum negative pressure extension, and the difficulty in ensuring the vacuum depth. Achieve the effect of improving the soft foundation treatment effect, avoiding viscous resistance and improving the reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

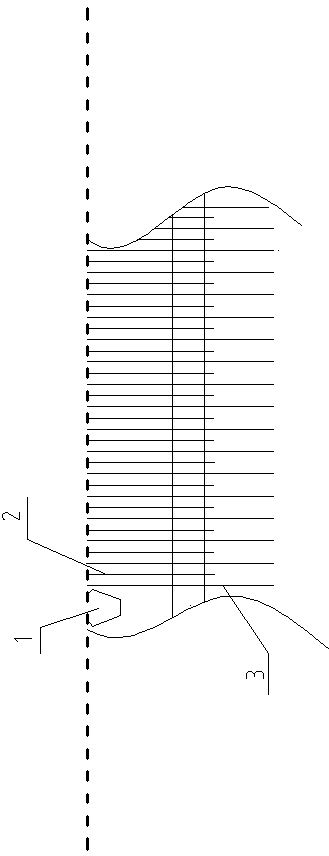

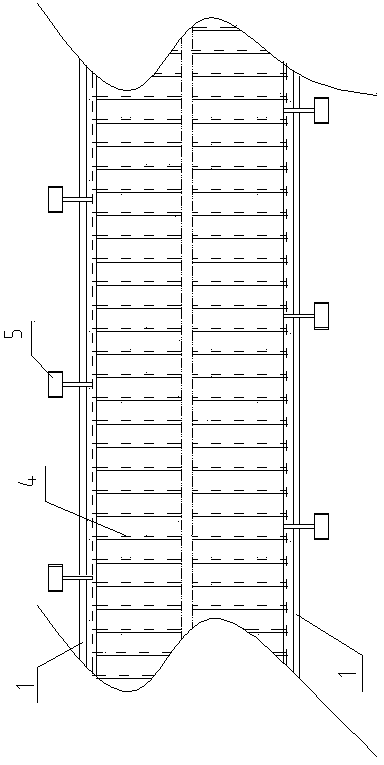

[0018] refer to figure 1 and figure 2 , a sandless vacuum preloading soft soil foundation reinforcement method, through two stages to strengthen the soft soil foundation, the first stage is the pre-consolidation treatment of the shallow surface layer, when the bearing capacity of the shallow surface layer reaches the set value, the second stage is carried out Stage deep long slab vacuum preloading reinforcement treatment,

[0019] Specific steps are as follows,

[0020] The first stage of shallow surface pre-consolidation treatment: First, dig a pressure film ditch 1, lay a layer of woven cloth on the surface of the soft ground to provide bearing capacity for the subsequent laying of the vacuum pipe network, and then lay the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com