Reinforced prestressed concrete corrugated sheet pile with rotating shaft

A corrugated sheet pile and prestressing technology, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, can solve problems such as insufficient shear strength, slow construction, and easy deformation, and achieve ecological balance and good soil retaining effect , Good water stop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

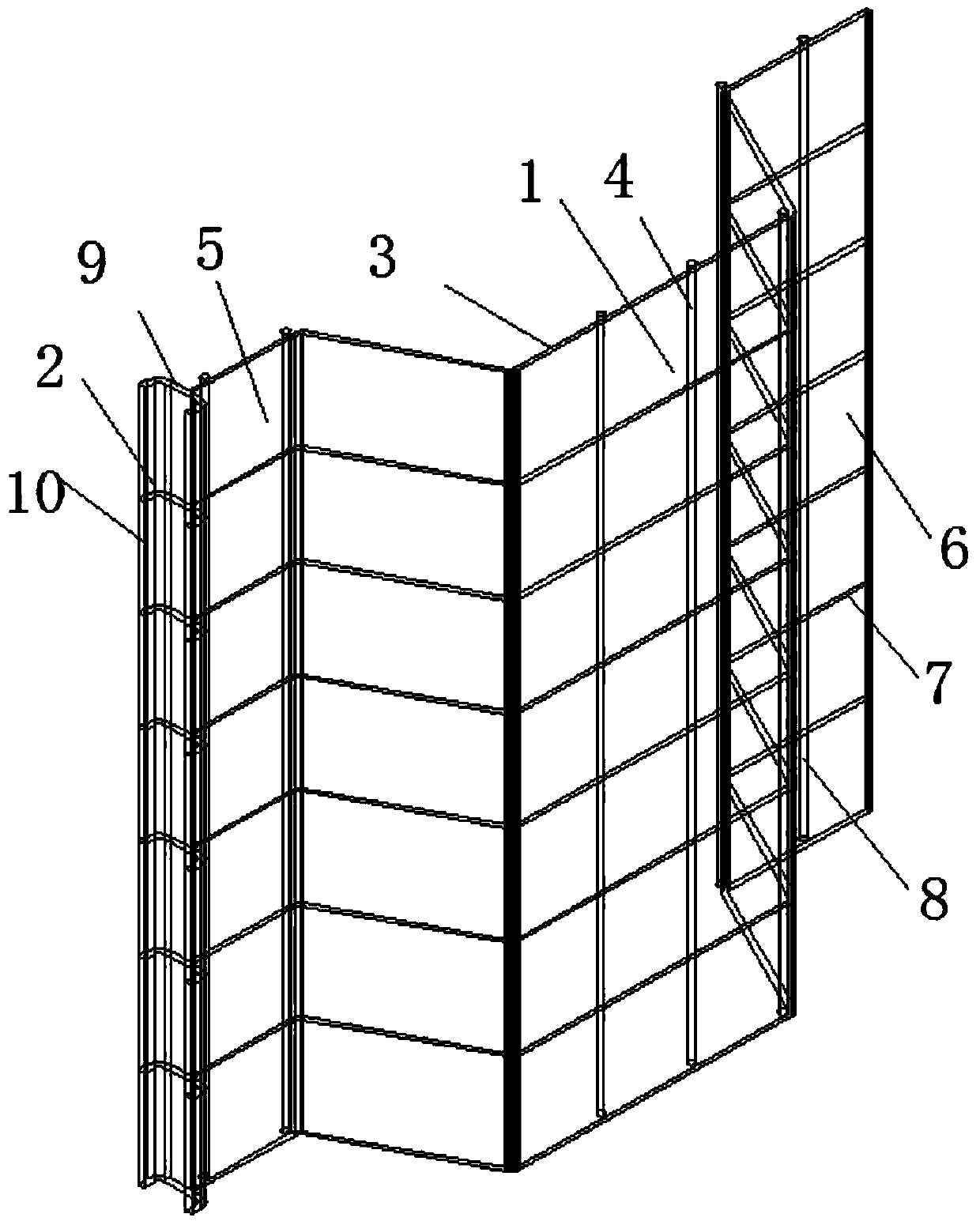

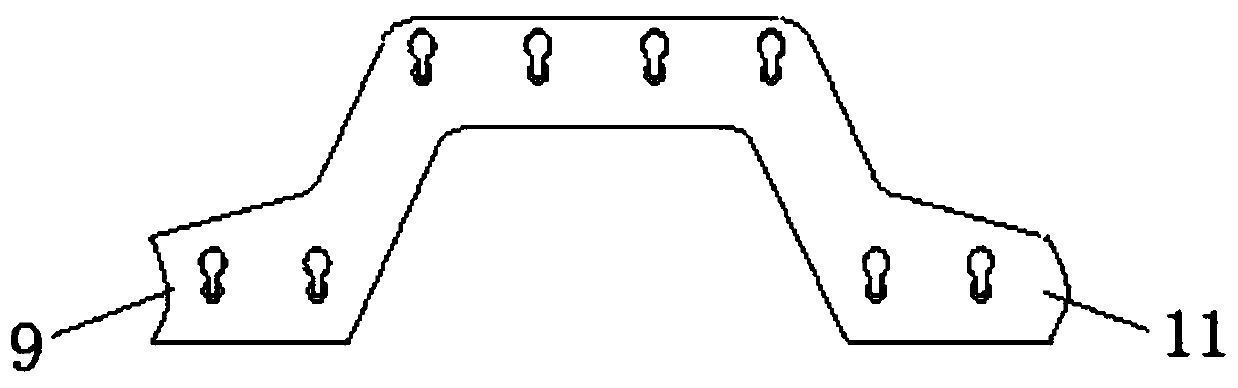

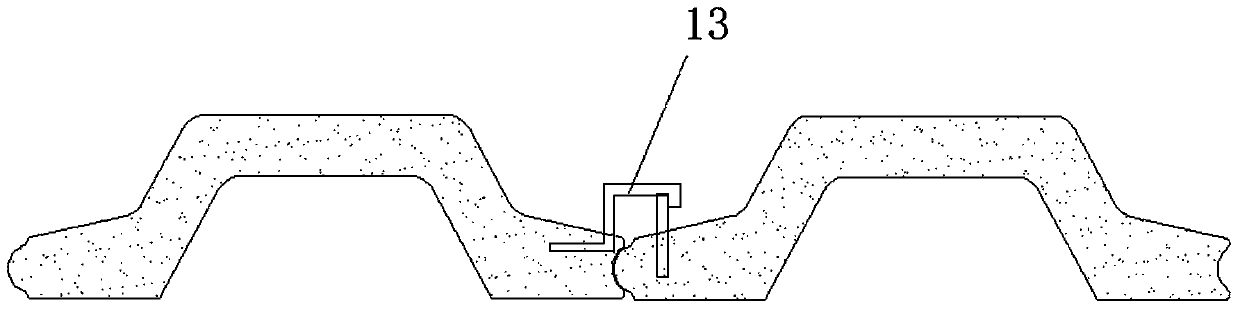

[0018] Such as Figure 1-3 As shown, the shaft-type reinforced prestressed concrete corrugated sheet pile of the present invention includes a main body part 1 protruding from the front side to the rear side, a bent steel plate 2 and concrete, and the main body part consists of multiple groups of first stirrup bars 3 arranged transversely and Multiple sets of vertically arranged first prestressed main reinforcements 4 are staggered to form a reinforcement cage, and concrete is arranged in the reinforcement cage. The two sides of the main body part 1 are respectively provided with a first wing plate 5 and a second wing plate 6, and the first wing plate 5 and the second wing plate 6 are formed by multiple sets of horizontally arranged second stirrups 7 and multiple sets of vertically arranged second prestressed main ribs 8, and the bent steel plate 2 is formed by multiple sets of horizontally installed fillets. Grooved steel plates 9 and multiple sets of vertically installed thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com