Structural system and method of prefabricated garage based on prefabricated piles

A prefabricated pile and prefabricated technology, applied in infrastructure engineering, underwater structures, sheet pile walls, etc., can solve the problems of small vertical load, waste, low construction efficiency, etc., to increase the bending resistance and ductility, The effect of reducing pollutant emissions and ensuring structural accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing of description and specific embodiment:

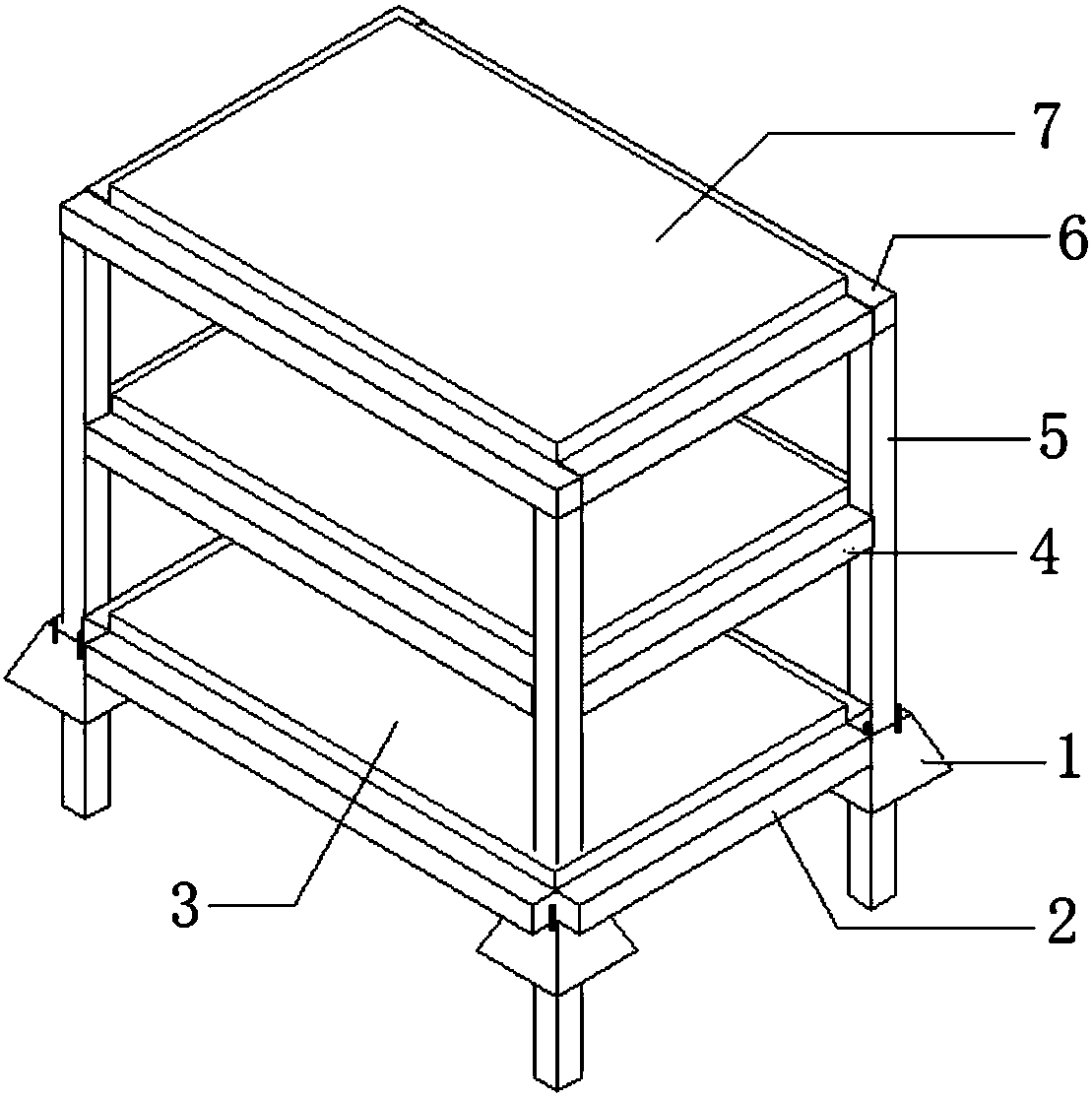

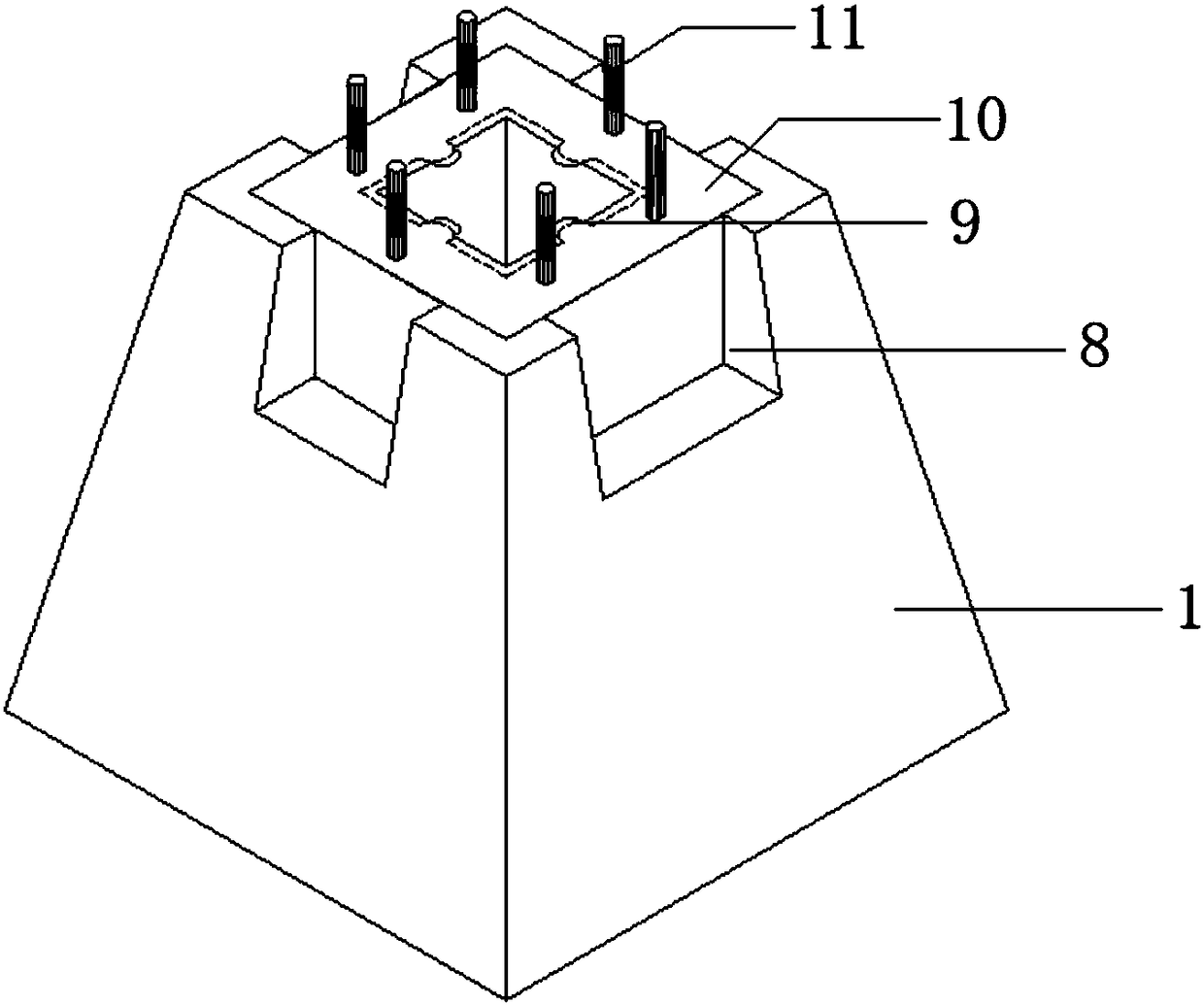

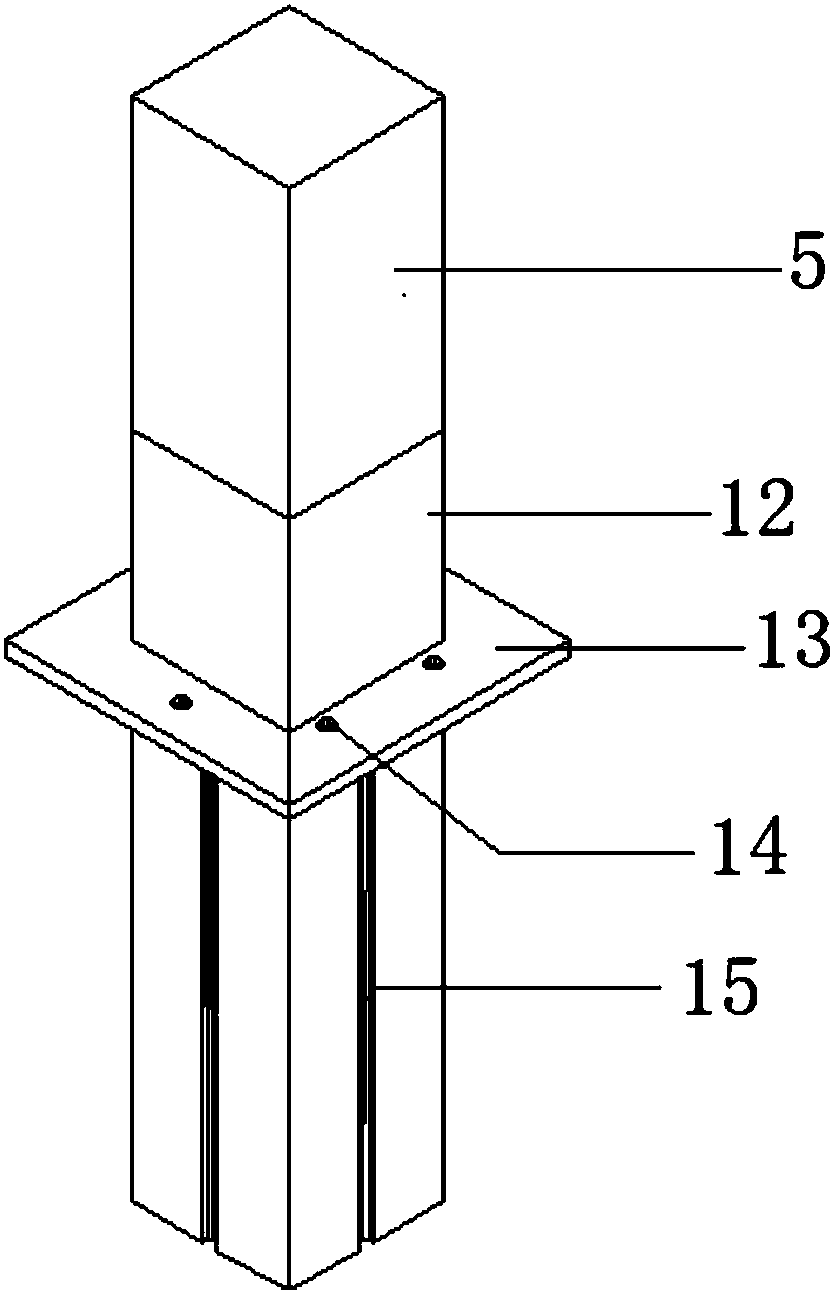

[0040] Such as figure 1 As shown, a new prefabricated garage structure system based on prefabricated piles, including: multiple prefabricated square independent foundations 1, multiple prefabricated ground beams 2, multiple prefabricated waterproof bottom plates 3, multiple prefabricated piles 5, multiple floor A composite beam 4, a composite beam 6 at the top of a plurality of piles, and a plurality of composite plates 7. In the foundation pit that has been dug, the prefabricated square independent foundation 1 is hoisted to the positioning point by setting out wire positioning, and adjusted to the level. The prefabricated ground beam 2 is hoisted and placed inside the groove of the prefabricated square independent foundation 1, and the joints are filled with fine concrete. Lift the prefabricated pile 5 and align it with the reserve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com