Prefabricated assembly well wall structure and construction method thereof

A prefabricated assembly and well wall technology, which is applied in the configuration of water supply devices, drainage structures, and water supply pools, etc., can solve the problems of long exposure time of foundation pit walls, complicated wet operation procedures, and difficulty in quality assurance, and it is easy to achieve engineering quality. Control and solve the effect of water supply and slurry supply and mud discharge for multiple equipments, and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail below in conjunction with accompanying drawing:

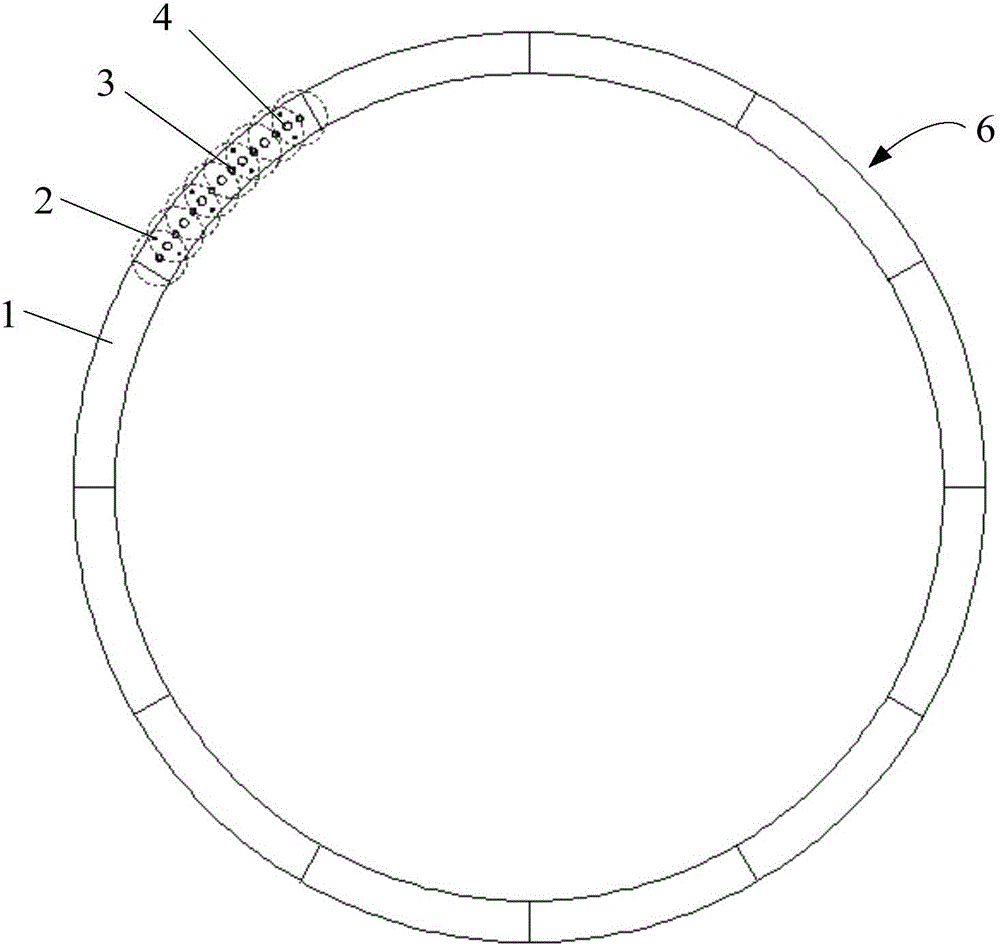

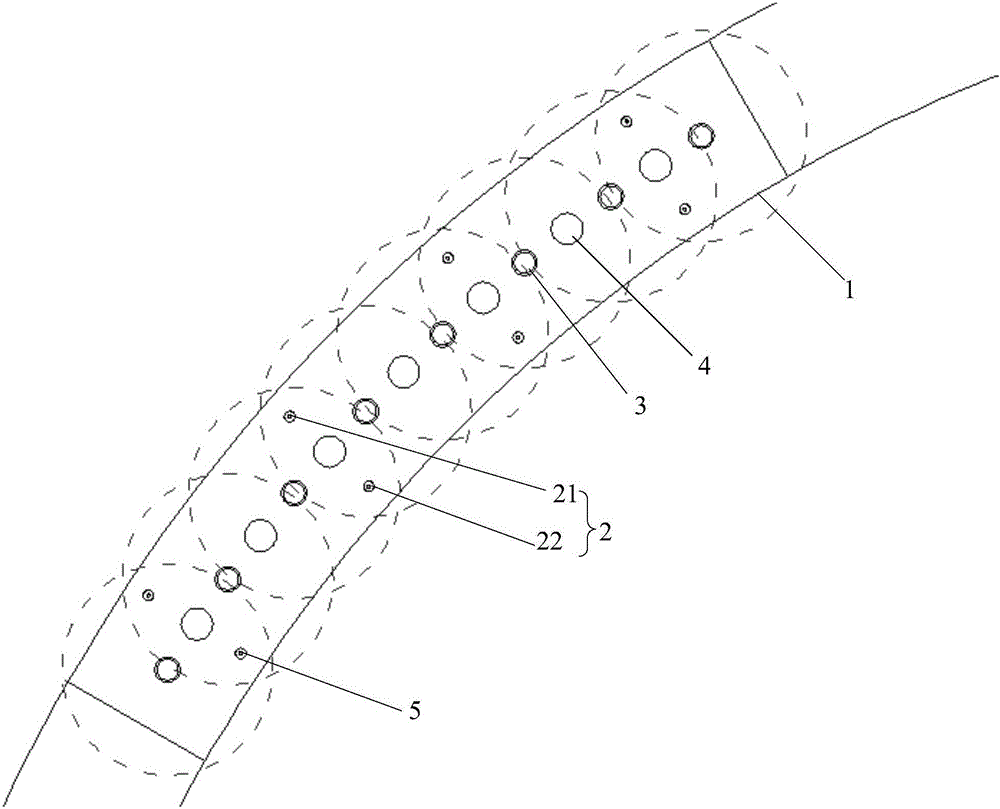

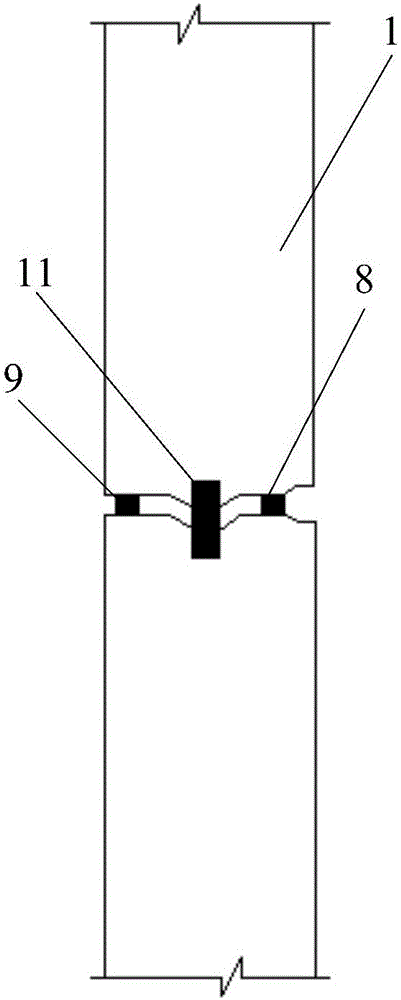

[0034] Such as Figure 1-5 As shown, the present invention provides a prefabricated well wall structure, which is assembled by splicing and assembling a number of prefabricated segments 1 along the longitudinal and circumferential directions. The prefabricated segments 1 are provided with a number of prestressed through holes 2 running through the upper and lower ends at intervals. , a number of grouting holes 3 and a number of grouting holes 4, the prestressed through hole 2 is provided with a prestressed connector 5, the prestressed connector 5 stretches out from the upper and lower ends of the prestressed through hole 2 , both circumferential ends of the inner side of the prefabricated segment 1 are provided with oblique inner holes, and oblique connecting sleeves 10 or oblique bolts 12 are pre-embedded in the oblique inner holes, and the outer diameter of the oblique bolts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com