Method for preparing biodiesel oil by using wet alga biomass microwave-heating one-step method

A technology of biodiesel and microwave heating, which is applied in the fields of biofuel, petroleum industry, fat production, etc., can solve the problems of energy consumption in dehydration and drying, and the production of biodiesel without in-depth analysis of microalgae cell wall breaking efficiency, so as to save energy consumption , The effect of simplifying the complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

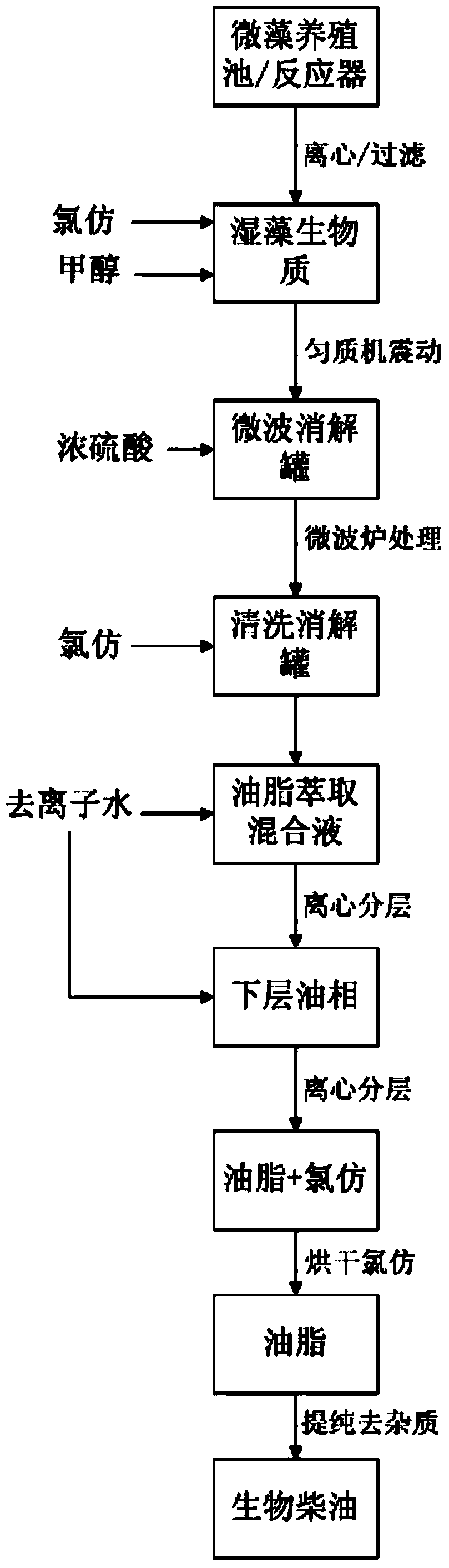

Embodiment 1

[0032] Take rhizome liquid with a biomass density of 1g / L, and the oil content of the dry weight of the algae cells is 40%, and use the suction filtration method to dehydrate the microalgae liquid to obtain wet algae biomass with a solid water content of 60%. Weigh 1g of wet algal biomass into a centrifuge tube, add 4ml of chloroform and 4ml of methanol, and vibrate on a homogenizer for 20s. Then pour it into 4 microwave digestion tanks, each with a capacity of 50ml. Then add 0.2ml concentration of 98% concentrated sulfuric acid into the digestion tank, seal the digestion tank and put it into a microwave oven, the frequency of microwave treatment is 2450MHz. Set the microwave power to 500w for 40s, when the temperature of the microwave digestion tank reaches 60 degrees Celsius, reduce the microwave power to 400w and keep the temperature constant for 60min. After microwave treatment, cool for 10 minutes to reduce the temperature of the digestion tank to 30 degrees Celsius, and...

Embodiment 2

[0035] The chlorella liquid with a biomass density of 5g / L was taken, and the oil content of the dry weight of the algal cells was 70%, and the wet algae biomass with a solid water content of 40% was obtained after the microalgae liquid was dehydrated by a centrifugal method. Weigh about 50g of wet algae biomass into a centrifuge tube, add 50ml of chloroform and 50ml of methanol, and vibrate on a homogenizer for 30s. Then pour it into 7 microwave digestion tanks, each with a capacity of 170ml. Then add 2.5ml of concentrated sulfuric acid with a concentration of 98% in the digestion tank, seal the digestion tank and put it into a microwave oven. The frequency of microwave treatment is 2450MHz. Set the microwave power to 800w for 60s, when the temperature of the microwave digestion vessel reaches 80 degrees Celsius, reduce the microwave power to 500w and keep the temperature constant for 30min. After microwave treatment, cool for 15 minutes to reduce the temperature of the dige...

Embodiment 3

[0038] Take the spirulina liquid with a biomass density of 10g / L, the oil content of the dry weight of the algal cells is 10%, and use the filter press method to dehydrate the microalgae liquid to obtain wet algae biomass with a solid water content of 90%. Weigh 100g of wet algae biomass into a centrifuge tube, add 100ml of chloroform and 100ml of methanol, and vibrate on a homogenizer for 40s. Then pour it into 10 microwave digestion tanks, each with a capacity of 300ml. Then add 5ml of concentrated sulfuric acid with a concentration of 98% in the digestion tank, seal the digestion tank and put it into a microwave oven. The frequency of microwave treatment is 915MHz. Set the microwave power to 1000w for 80s, when the temperature of the microwave digestion tank reaches 90 degrees Celsius, reduce the microwave power to 600w and keep the temperature constant for 2min. Cool for 20 minutes after microwave treatment to reduce the temperature of the digestion tank to 25 degrees Cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com