Process of melt-spinning polyacrylonitrile fiber

a polyacrylonitrile fiber and melt-spinning technology, applied in the field of carbon fiber processing technology, can solve the problems of reducing the development of the carbon fibre industry in china, reducing the quality of homemade precursor fibres, and reducing the number of defects, cracks and voids, etc., to achieve the effect of reducing side reaction, improving pre-oxidization degree, and reducing cost and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

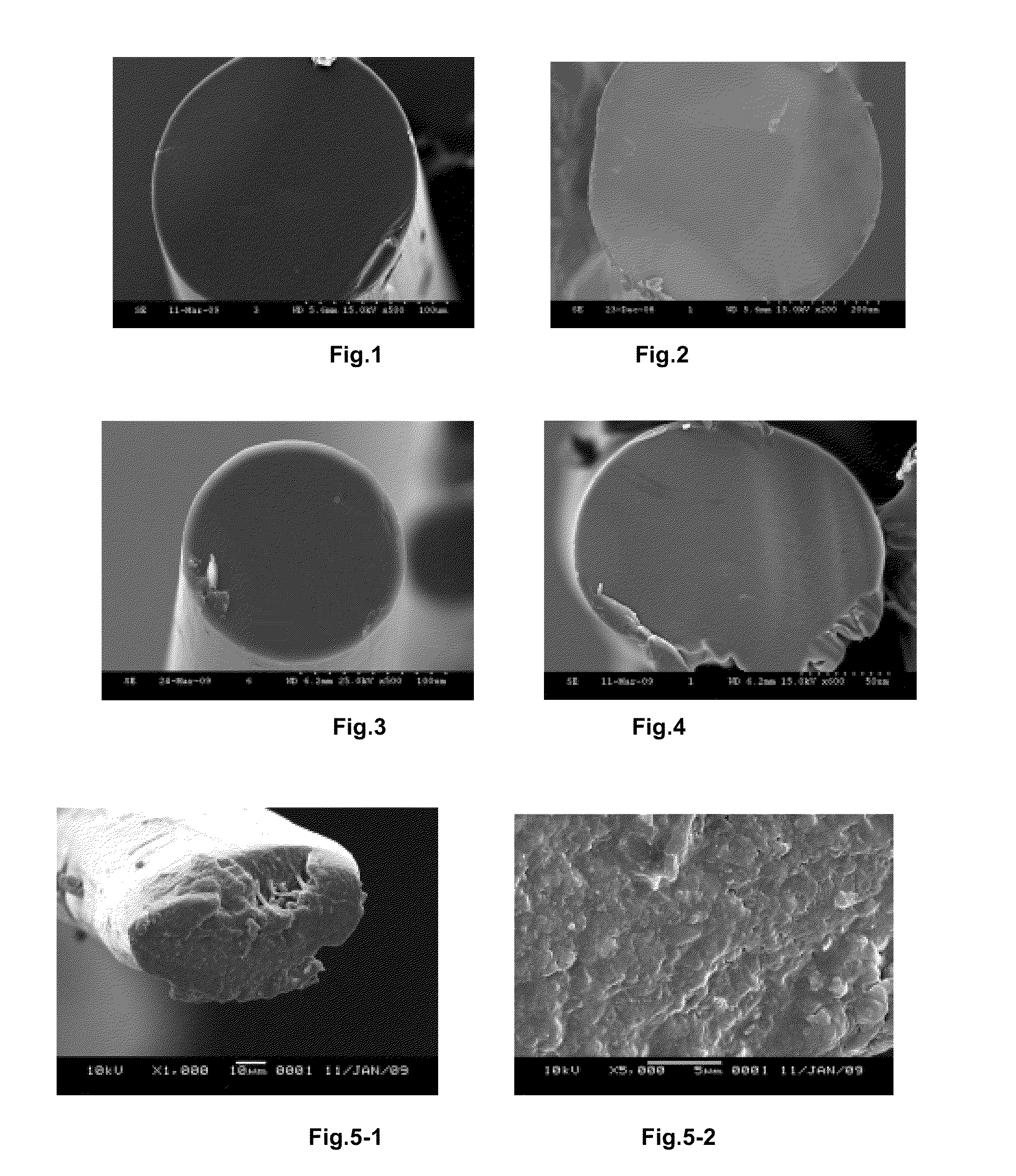

[0118]First, 5 g anhydrous PAN powder and 95 g DMSO solvent are uniformly mixed in a three-neck flask, while heated in an oil bath maintained at a temperature of 70° C., and stirred to completely dissolve PAN powder. After the PAN powder is dissolved, 2 g distilled water is added. Upon mechanical stirred for one hour, the slurry is transferred to a spinning machine for spinning, and the PAN based precursor fibre obtained by the gel spinning (in which the spinning temperature is 60° C., the coagulation bath temperature is 10-20° C., the primary washing temperature is 75° C., the secondary temperature is 100° C.) has a tensile strength of 4.31 GPa. FIG. 1 shows a SEM photograph (magnification factor of which is 15, 000) of PAN based precursor fibre spun from a spinning solution containing 2 wt. % gelling agent based on the total weight of the solution. It can be seen from FIG. 1 that the cross-section of the obtained PAN based precursor fibre is circle nearly without voids across the ...

example 2

[0119]First, 10 g anhydrous PAN powder and 90 g DMF solvent are uniformly mixed in a three-neck flask, while heated in an oil bath maintained at a temperature of 90° C., and stirred to completely dissolve the PAN powder. After the PAN powder is dissolved, 3 g ethylene glycol is added. Upon mechanical stirred for one hour, the slurry is transferred to a spinning machine for spinning, and the PAN based precursor fibre obtained by the gel spinning (the spinning condition is the same as those in example 1) has a tensile strength of 4.4 GPa. FIG. 2 shows a SEM photograph (magnification factor of which is 15, 000) of PAN based precursor fibre spun from a spinning solution containing 3 wt. % gelling agent based on the total weight of the solution. It can be seen from FIG. 2 that the cross-section of the obtained PAN based precursor fibre is circle nearly without voids across the section, and the precursor fibre is structural compact and skin-core structure is not observed.

example 3

[0120]First, 10 g anhydrous PAN powder and 90 g DMAc solvent are uniformly mixed in a three-neck flask, while heated in a sand bath maintained at a temperature of 90° C., and stirred to completely dissolve the PAN powder. After the PAN powder is dissolved, 4 g ethylene glycol is added. Upon mechanical stirred for one hour, the slurry is transferred to a spinning machine for spinning, and the PAN based precursor fibre obtained by the gel spinning (the spinning condition is the same as those in example 1) has a tensile strength of 4.2 GPa. FIG. 3 shows a SEM photograph (magnification factor of which is 25, 000) of PAN based precursor fibre spun from a spinning solution containing 4 wt. % gelling agent based on the total weight of the solution. It can be seen from FIG. 3 that the cross-section of the obtained PAN based precursor fibre is circle nearly without voids across the section and the precursor fibre is structural compact.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com