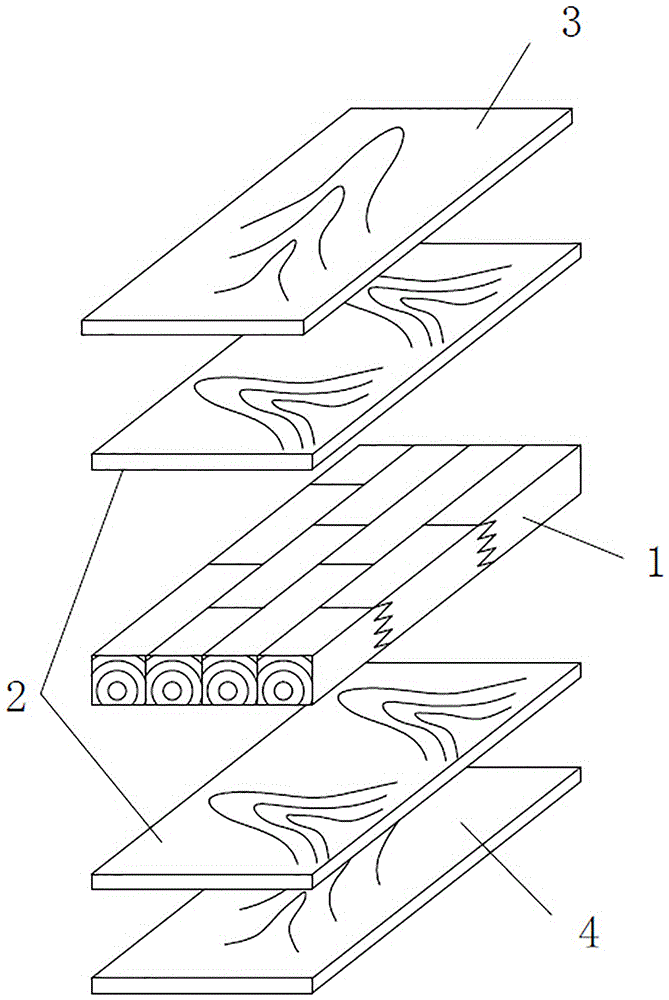

Multilayered-frame solid wood floor and manufacturing method thereof

A multi-layer frame and manufacturing method technology, applied in the direction of wood layered products, chemical instruments and methods, lamination, etc., can solve the problems of increasing manufacturing costs, reducing material mechanical properties, and high production costs, achieving low production costs, The product has good mechanical properties and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: a kind of manufacture method of solid wood multilayer frame floor, comprising:

[0028] a. The steps of raw material preparation, including the preparation process of the surface board, the preparation process of the balance layer veneer and the preparation process of the core board narrow material;

[0029] b. The step of raw material humidity control, including the humidity control process of the surface plate and the humidity control process of the balance layer veneer. The humidity control process of the surface plate is to first place the surface plate material at a temperature of 60 ° C and a relative humidity of 65 ° C. % in an environment with a moisture content of 9 to 11%, and then the surface material is placed in an environment with a temperature of 40°C and a relative humidity of 65% to a moisture content of 12 to 13%; the adjustment of the balance layer veneer The wet process is to first place the balance layer veneer material in an environme...

Embodiment 2

[0034] Embodiment 2: a kind of manufacturing method of solid wood multilayer frame floor, comprising:

[0035] a. The steps of raw material preparation, including the preparation process of the surface board, the preparation process of the balance layer veneer and the preparation process of the core board narrow material;

[0036] b. The step of raw material humidity control, including the humidity control process of the surface plate and the humidity control process of the balance layer veneer. The humidity control process of the surface plate is to first place the surface plate material at a temperature of 70°C and a relative humidity of 75°C. % in an environment with a moisture content of 9 to 11%, and then the surface material is placed in an environment with a temperature of 50°C and a relative humidity of 75% to a moisture content of 13 to 14%; the adjustment of the balance layer veneer The wet process is to first place the balance layer veneer material in an environment...

Embodiment 3

[0041] Embodiment 3: a kind of manufacturing method of solid wood multilayer frame floor, comprising:

[0042] a. The steps of raw material preparation, including the preparation process of the surface board, the preparation process of the balance layer veneer and the preparation process of the core board narrow material;

[0043] b. The step of raw material humidity control, including the humidity control process of the surface plate and the humidity control process of the balance layer veneer. The humidity control process of the surface plate is to first place the surface plate material at a temperature of 65°C and a relative humidity of 70°C. % in an environment with a moisture content of 9 to 11%, and then the surface material is placed in an environment with a temperature of 45°C and a relative humidity of 75% to a moisture content of 13 to 14%; the adjustment of the balance layer veneer The wet process is to first place the balance layer veneer material in an environment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap