Installation method of concrete conveying pump pipes of super high-rise building

A technology of a concrete delivery pump and an installation method, which is applied in the construction, building structure, construction material processing and other directions, can solve the problems of safety hazards, low reliability, environmental impact, etc. The effect of increasing security and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

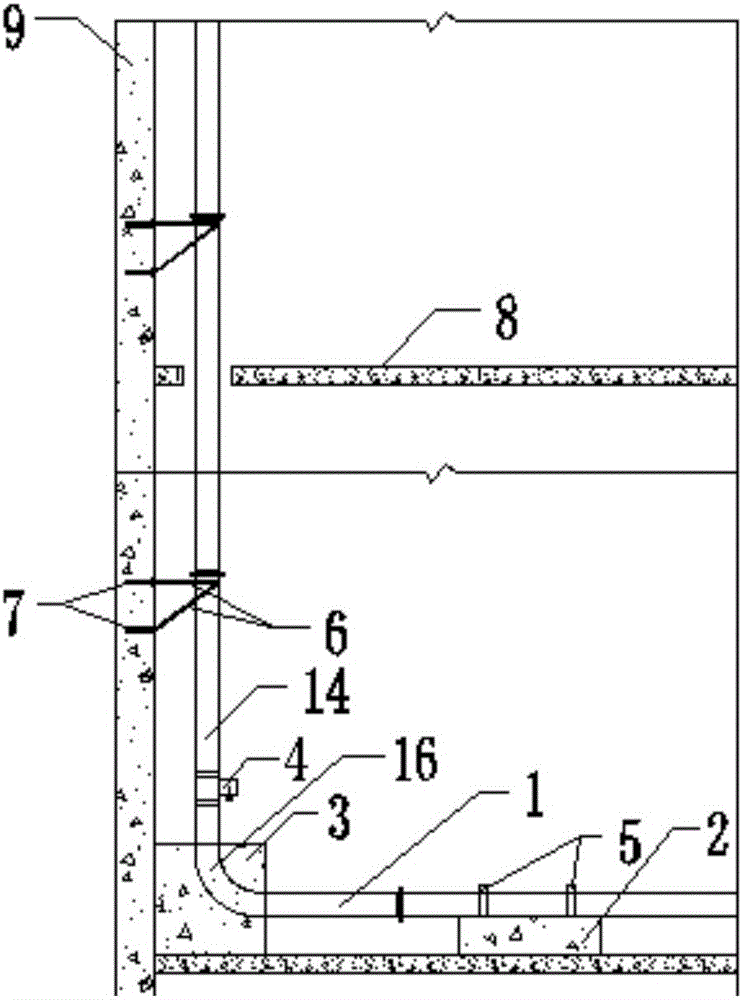

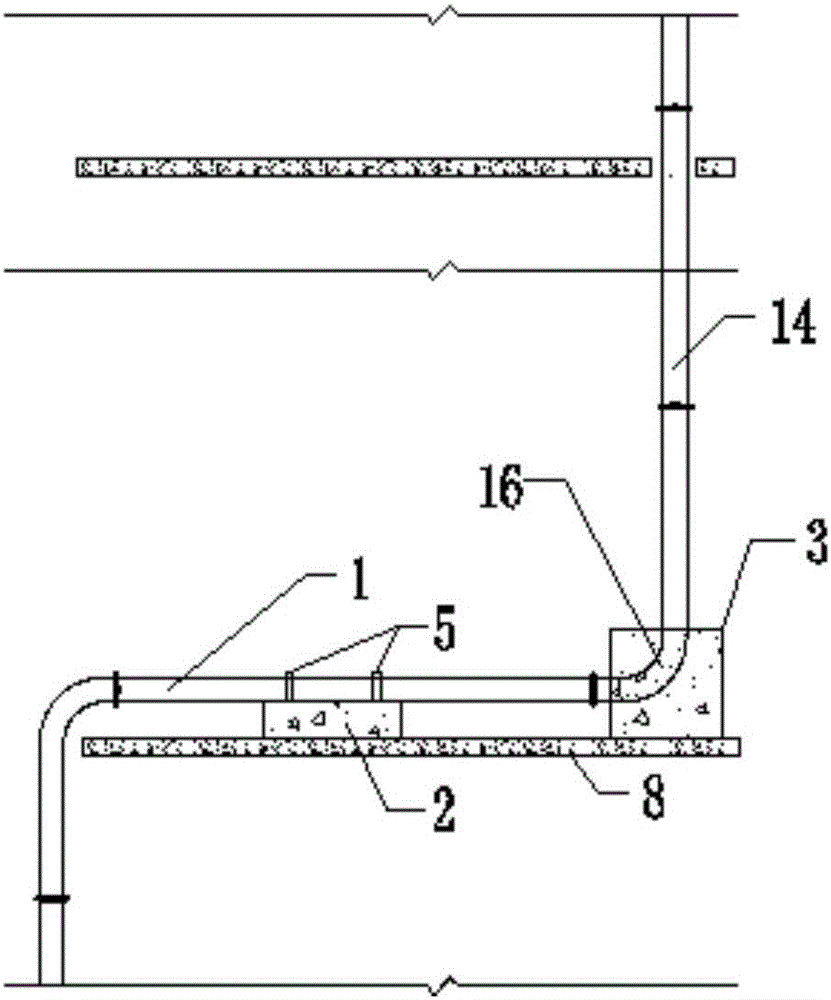

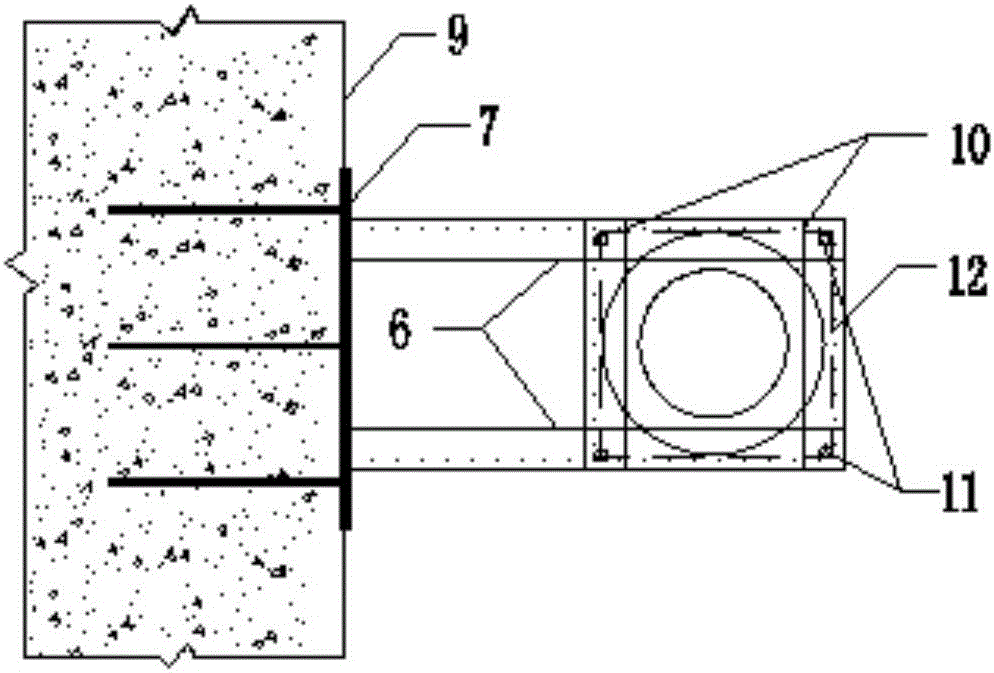

[0023] Such as Figure 1-6 As shown, a method for installing a super high-rise building concrete delivery pump pipe of the present invention is characterized in that: the horizontal pump pipe 1 in the first floor is fixed in the prefabricated concrete pier 2, and the horizontal pump pipe 1 on the first floor is connected with the vertical pump pipe Concrete fixed pier 3 is poured at the elbow 16 at the elbow 16, and the elbow 16 is wrapped and fixed to reduce vibration and make it more firm. The vertical pump pipe 14 is fixed by a shaped triangular rigid bracket attached to the wall. The fixed position is the flange connection of the pump pipe. Bearing the vertical vibration and gravity of the pump tube, the bracket is welded on the pre-embedded iron parts of the wall 9, and a rubber ring 12 is placed on the angle steel bracket to eliminate the level difference of the bracket and buffer during pumping; the vertical pump tube 14 wears Openings shall be reserved for the floor sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com