Self-lubricating water and gas injection method and structure of rotary excavation equipment

A kind of equipment and air hole technology, applied in drilling equipment and methods, drilling equipment, earthwork drilling and production, etc., can solve the problems affecting the performance of the drill bit and construction progress, achieve good sealing effect and improve the effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with specific embodiment the embodiment of the present invention is further described:

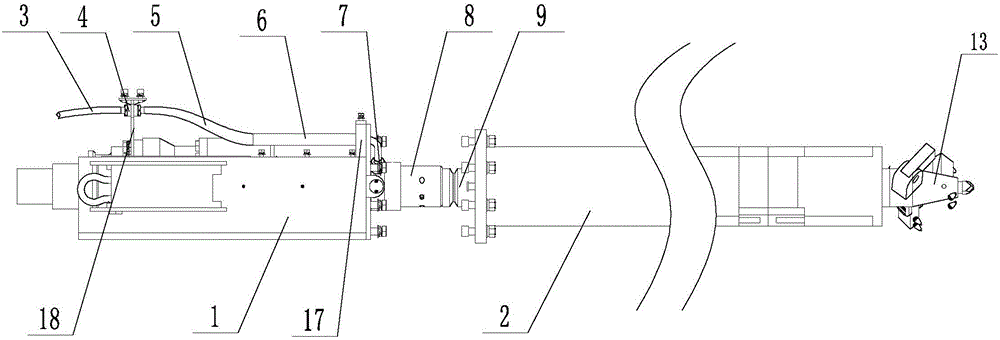

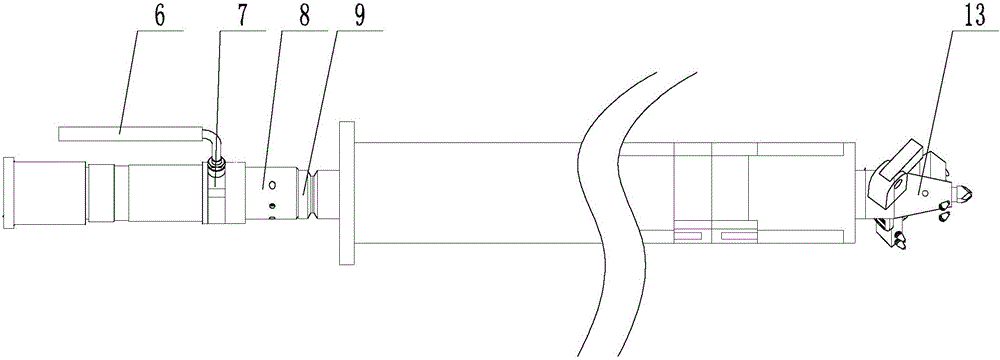

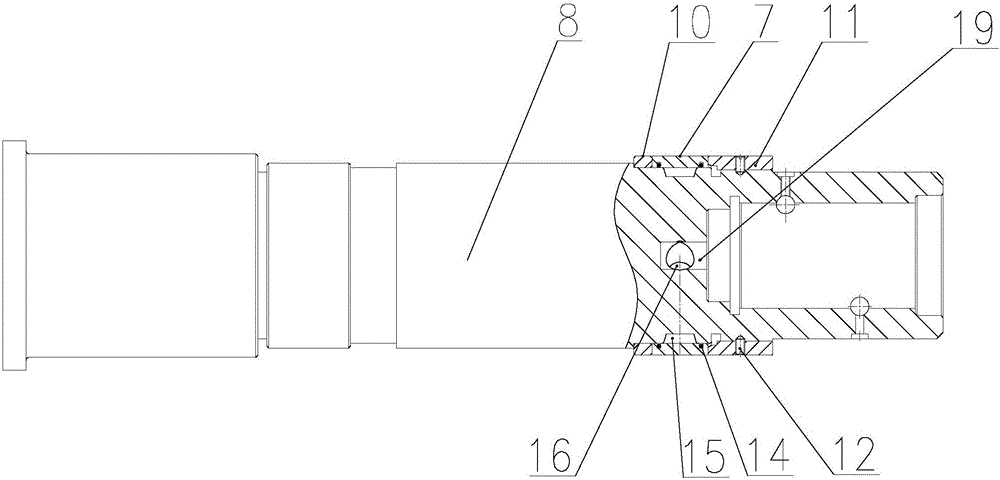

[0016] Such as Figure 1-Figure 3 Shown, a kind of self-lubricating water injection of rotary digging equipment, gas injection method, this method is in rotary digging equipment rotary main shaft 8 and the drilling rod 2 that is connected with it, drill bit 13 inside setting central water / gas hole 19, in The water injection / air hole 16 on the rotating main shaft 8 is installed with a rotating sealing sleeve 7, and a cavity 15 is left between the rotating main shaft 8 and the rotating sealing sleeve 7, and the water / air source is connected to the outside through the rotating sealing sleeve 7. When the rotating main shaft 8 rotates At this time, the rotating sealing sleeve 7 is relatively fixed with the external water / air source, and rotates relatively with the rotating main shaft 8; the high-pressure water / air fills the cavity 15 through the rotating sealing slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com