Method for vertical shaft electric-heating-assisted depressurizing production of natural gas hydrate reservoir

A natural gas and hydrate technology, which is applied in the field of natural gas hydrate reservoir exploitation, can solve problems such as reservoir damage, application limitations, and high economic costs, and achieve the effects of easy control, enhanced recovery, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

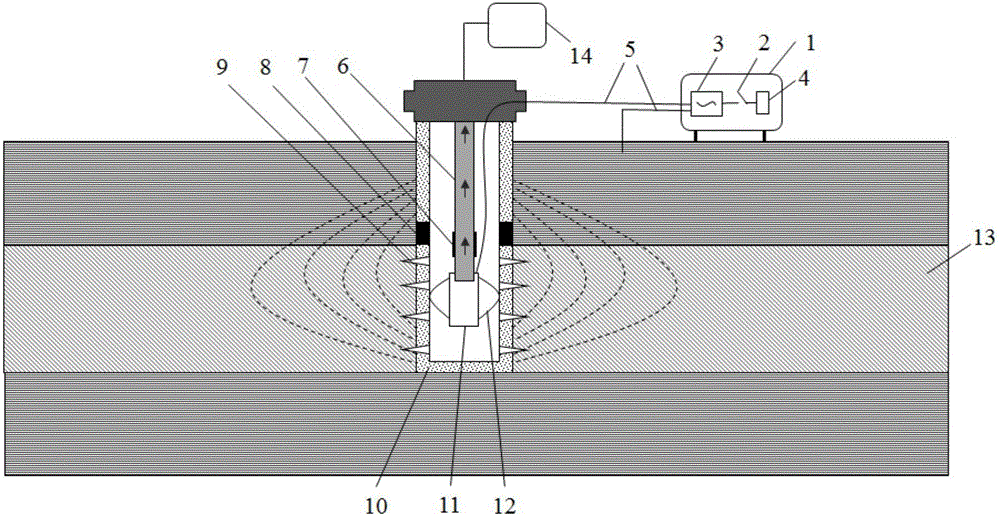

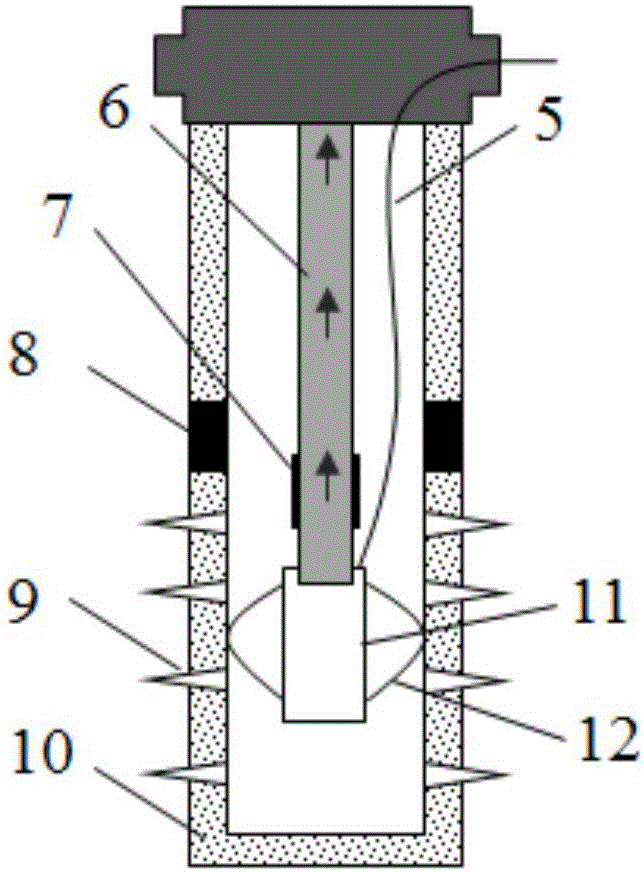

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings, but the implementation scope of the present invention is not limited.

[0017] (1) According to the geological data of natural gas hydrate reservoirs, a natural gas hydrate reservoir with an average effective thickness of 30 m is selected, a vertical well is drilled, and the well is completed with casing 10, which is made of stainless steel. There is a glass fiber reinforced plastic casing 8 at the boundary, forcing the current on the stainless steel casing of the natural gas hydrate reservoir section to pass through the natural gas hydrate reservoir 13, so as to achieve the purpose of heating the natural gas hydrate reservoir. Object possession 13;

[0018] (2) Install the ground control cabinet 1. The control cabinet is composed of a power supply 4, power conditioning equipment 3 and switch 2, wherein the power supply 4 is used to provide the AC power required for he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com