Acoustic-wave measurement while drilling system and method for underground coal mine anti-explosion drilling track

A measurement-while-drilling and acoustic wave technology, which is applied in construction and other fields, can solve the problems of short working time, slow transmission signal, high sand content in mud, etc., and achieve the effect of simple and compact structure, easy operation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

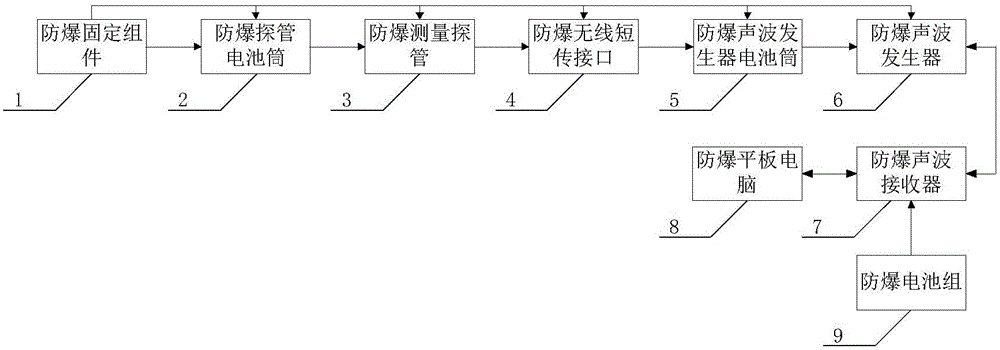

[0050] see figure 1 , the present invention consists of an explosion-proof fixed assembly 1, an explosion-proof measuring probe battery cartridge 2, an explosion-proof measuring probe 3, an explosion-proof wireless short transmission interface 4, an explosion-proof sound wave generator battery cartridge 5, an explosion-proof sound wave generator 6, an explosion-proof sound wave receiver 7, The explosion-proof tablet computer 8 and the explosion-proof battery pack 9 are composed of explosion-proof design, which can be applied in the explosive gas environment in underground coal mines. Before drilling, select the matching explosion-proof fixing component 1 according to the drilling tool specifications, and then connect the explosion-proof measuring probe battery tube 2, explosion-proof measuring probe 3, explosion-proof wireless short transmission interface 4, and explosion-proof sound wave generator through the explosion-proof fixing component 1. The battery cartridge 5 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com