Transistor assembling and dispensing machine

A technology of transistors and glue dispensers, which is applied to the device, material gluing, mechanical equipment and other directions for coating liquid on the surface, which can solve the problem of time-consuming, great influence on the reliability and accuracy of dispensing, and easy extrusion of pins. Deformation and other problems, to achieve the effect of accurate feeding position and ensure the accuracy of assembly and dispensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

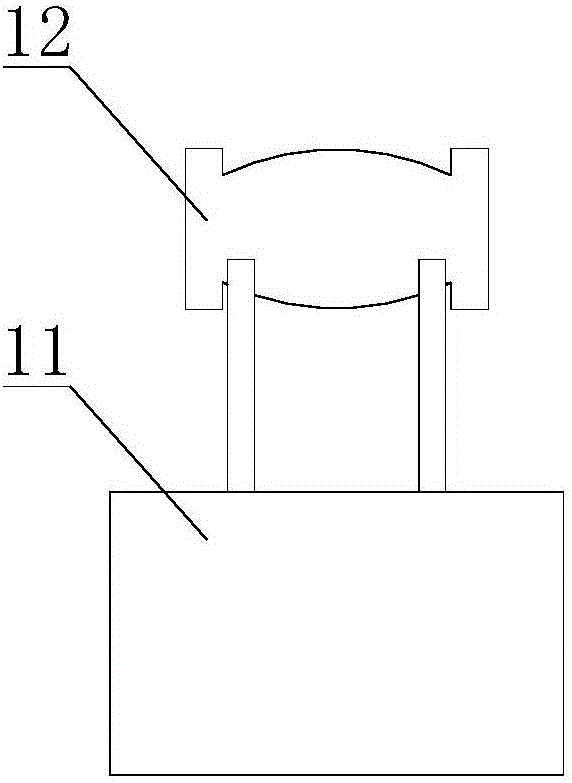

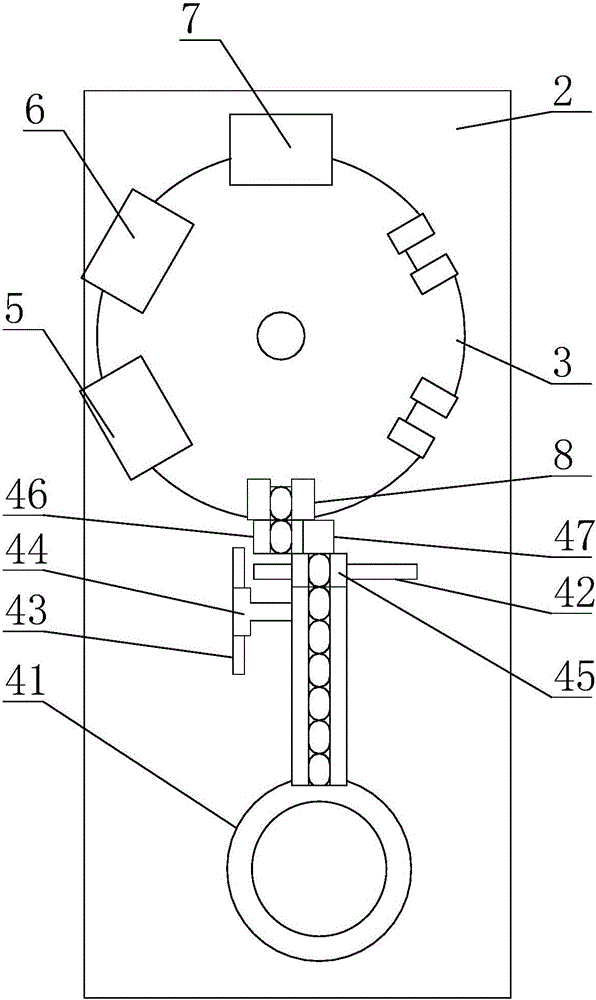

[0016] Such as figure 1 with 2 as shown, figure 1 It is a structural schematic diagram of a transistor assembly processed by a transistor assembly dispensing machine proposed by the present invention, figure 2 It is a structural schematic diagram of a transistor assembly dispensing machine proposed by the present invention.

[0017] refer to figure 1 , a transistor assembly dispensing machine proposed by the present invention is used for dispensing glue on transistor assemblies, the transistor assembly includes a casing 11 and a silicon chip 12 , and the silicon chip 12 is installed on the casing 11 .

[0018] refer to figure 2 , the transistor assembly dispensing machine includes: a workbench 2, a turntable 3, a shell feeding device, a silicon wafer feeding device 5, a dispensing device 6, a feeding device 7, and a driving device;

[0019] The turntable 3 is horizontally arranged on the workbench 2. The middle part of the turntable 3 is provided with a vertically arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com