Speck yarn spray-dyeing device

A technology of yarn and color dots, applied in the field of textile printing and dyeing, can solve the problems of low production efficiency and easy falling off of color dots, and achieve the effects of low cost, high equipment production efficiency and good comprehensive benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

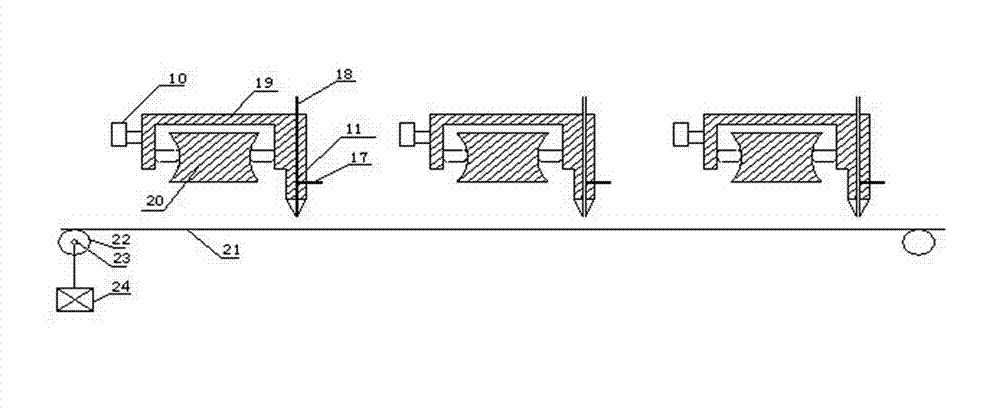

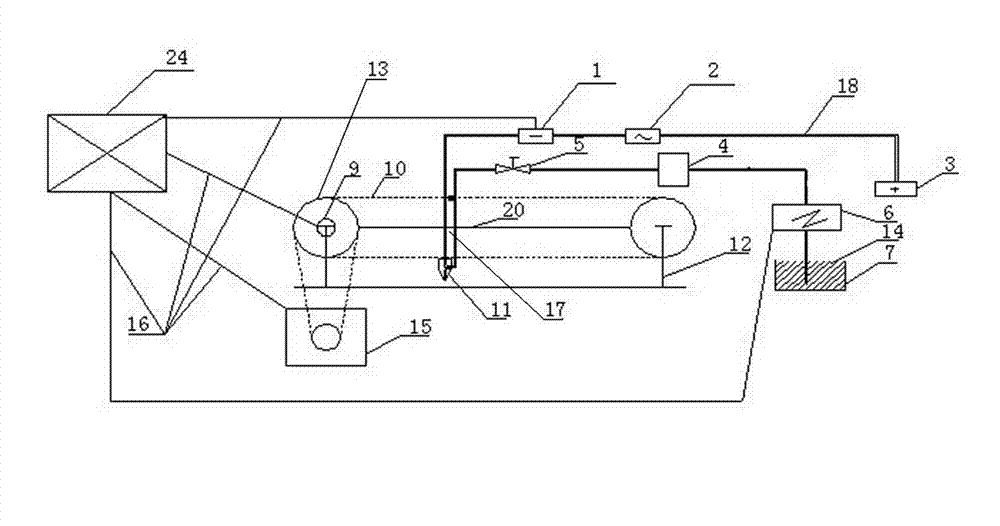

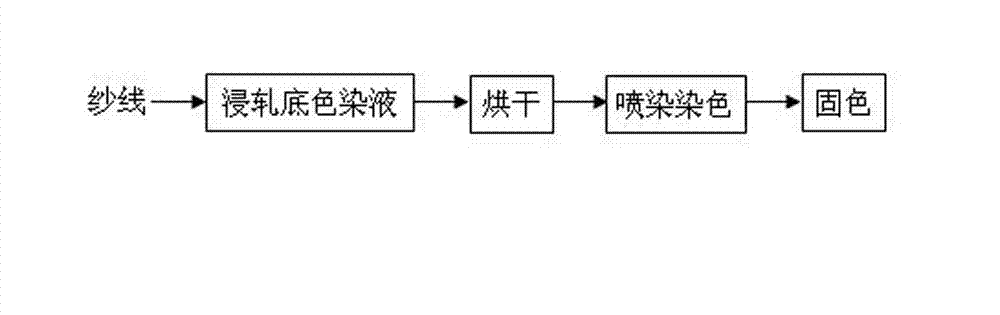

[0017] Below in conjunction with the accompanying drawings, the present invention will be further described through specific embodiments—the specific implementation device of the present invention and its application to 32s / 2 cotton yarn base color dyeing and color dot spray dyeing in one step.

[0018] Such as figure 1 , figure 2 As shown, three nozzles 11 are arranged back and forth along the direction of travel of the yarn, and each nozzle 11 is connected to the corresponding dyeing liquid configuration barrel 7 through a feeding pipe 17, through a shut-off valve 5, a pressure buffer 4, and a proportional pump 6. Each nozzle 11 is connected to the air compressor 3 through the air pipe 18, solenoid valve 1, and air pressure regulating valve 2 at the same time (the air compressor 3 can provide stable compressed air), and each nozzle 11 is installed on the mobile frame 19 , The mobile frame 19 is installed on the track 20, and the track 20 is fixed on the frame 12. The movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com