Nozzle with plasma exciters, nozzle array and burner

A plasma and exciter technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve problems such as easy oscillation and unstable combustion, improve accuracy and speed, reduce dwell time, and prevent return fire effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to specific embodiments and accompanying drawings.

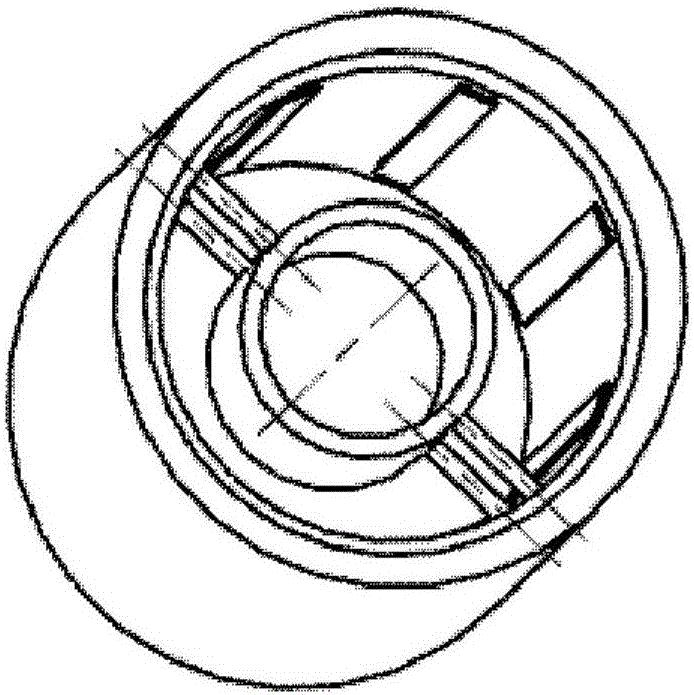

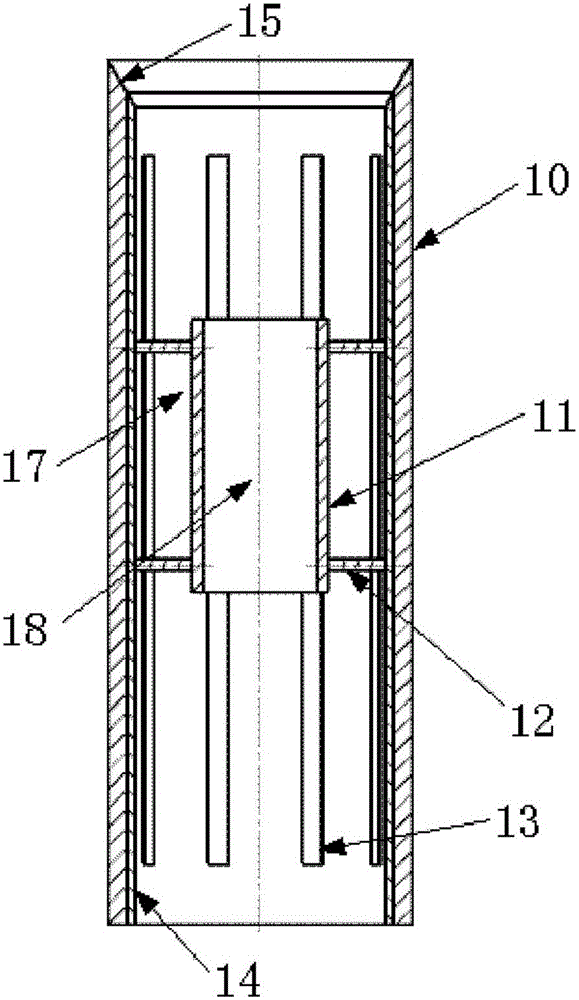

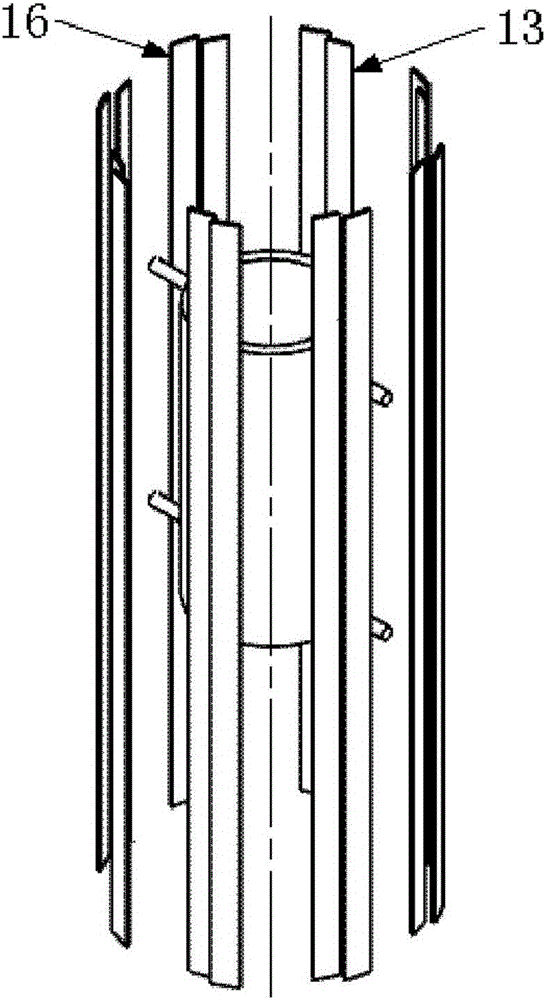

[0034] The nozzle with plasma exciter according to the first embodiment of the present invention includes: an outer cylinder 10, an N-layer intermediate cylinder, an inner cylinder 11 and a high-voltage power supply 20, the inner wall of the outer cylinder, the intermediate cylinder Both the inner wall and the outer wall of the cylinder are covered with an insulating material layer 14, and M exposed electrodes 13 and M buried electrodes 16 extending in the axial direction are alternately arranged on the insulating material layer 14, wherein two adjacent exposed electrodes 13 and buried electrodes 16 are formed. A plasma exciter, the exposed electrode 13 and the buried electrode 16 are respectively connected to the high-voltage end 21 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com