Sluicing force measurement device and testing method

A force measuring device and hydraulic technology, applied in the direction of measuring device, fluid dynamics test, machine/structural component testing, etc., can solve the problem of inability to obtain, and achieve the effect of easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

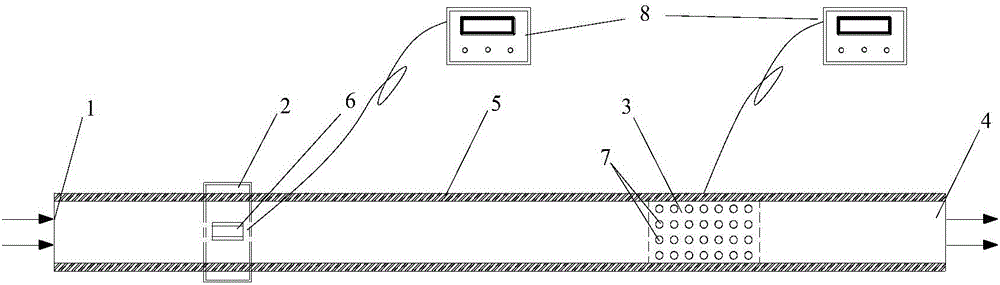

[0027] A hydraulic scouring force measuring device, simple in structure, convenient and practical, can be used as a device for measuring the hydraulic scouring force of water flow, to test the hydraulic scouring force of water flow at different flow rates, and to study the scouring effect of water flow on underwater structures. Provide a basis for rational design of the lower structure.

[0028] It specifically includes a water inlet 1 , a flow velocity measuring device 2 , a force measuring device 3 , a water outlet 4 and a test tube 5 . During the test, water flows into the test tube from the water inlet 1, and the water flow velocity can be measured through the flow velocity measuring device 2. The force measuring device 3 is composed of a series of high-precision pressure sensors 7, which can accurately test the scouring force of water flow at different flow rates. After completion, the water in the test tube is discharged from the water outlet 4, and a test cycle is compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com