Camera module optical filter gluing detection apparatus and method

A camera module, glue coating detection technology, applied in measurement devices, material analysis by optical means, instruments, etc., can solve problems such as untargeted solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

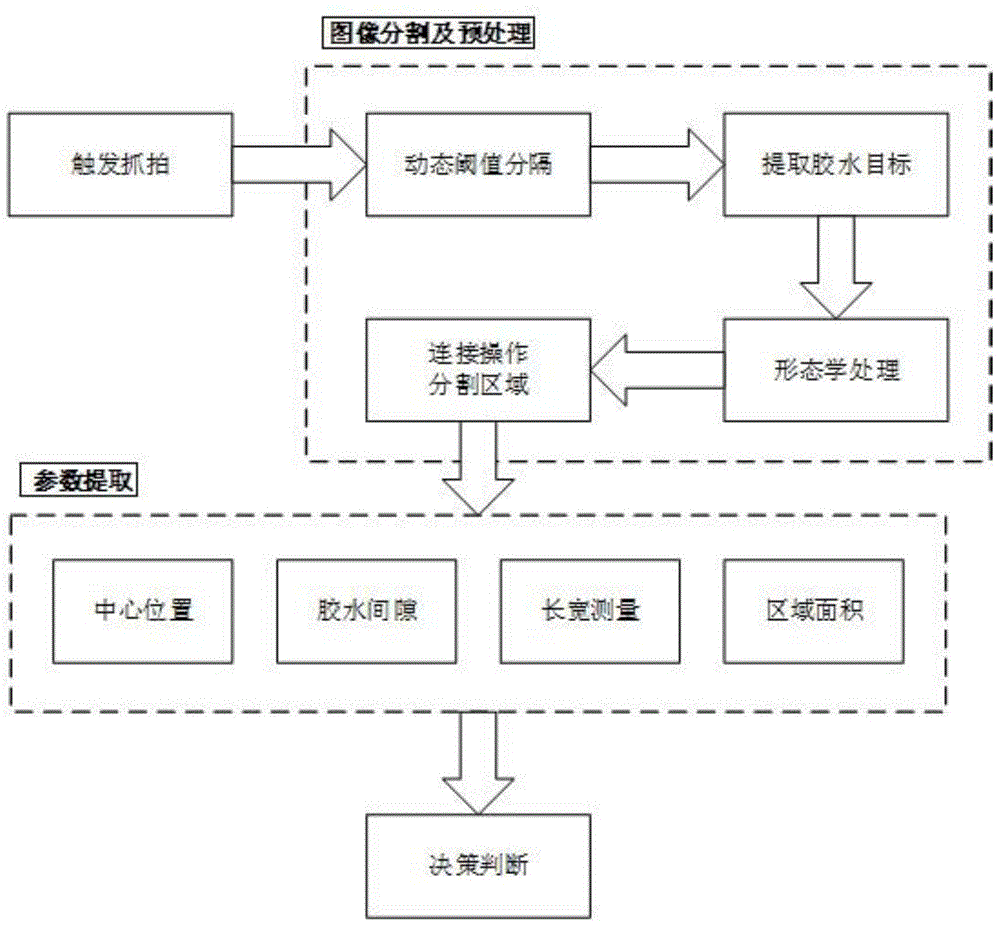

Method used

Image

Examples

Embodiment

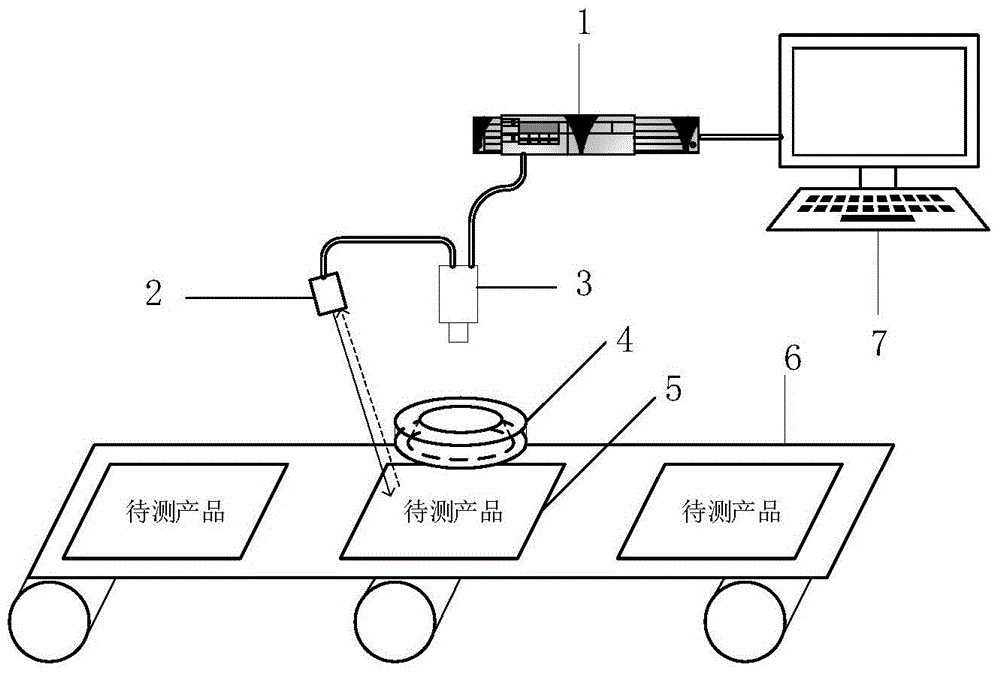

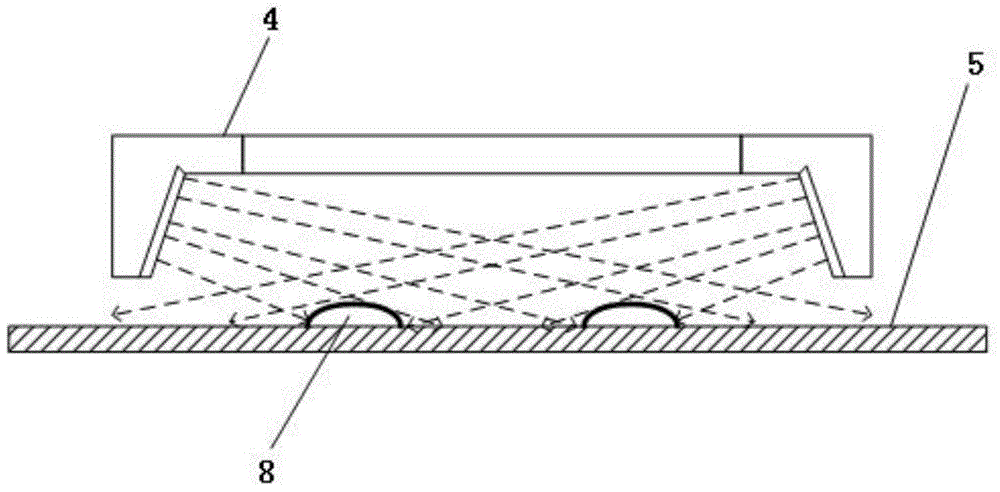

[0056] Example: figure 1 It is a schematic structural diagram of the camera module filter gluing detection device of the present invention, which includes: a conveyor belt 6 for transporting the camera module filter 5 to be detected, arranged above the conveyor belt 6, for The CCD camera 3 that the camera module filter 5 shoots, the low-angle ring light source 4 arranged near the camera 3, is arranged above the conveyor belt 6, is connected with the CCD camera 3, to control the CCD The camera 3 captures the photoelectric trigger 2 of the camera module filter 5 , and the server 7 connected with the CCD camera 3 and capable of analyzing and processing the images captured by the CCD camera 3 . The low-angle ring light source 4 is close to the product to be tested and projects light from all around.

[0057] In this example, the server 7 is a computer, and the server 7 and the CCD camera 2 are connected by Ethernet, and Ethernet is used for data exchange. figure 1 Reference nume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com