Circulating aging device and automatic assembly line

A technology for aging devices and boards, which is applied to measuring devices, measuring device shells, instruments, etc., can solve the problems of poor consistency of lamps, easy falling of lamps, and high aging costs, so as to reduce aging costs, avoid lamps from falling, and ensure consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

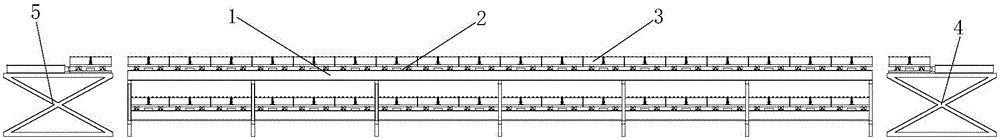

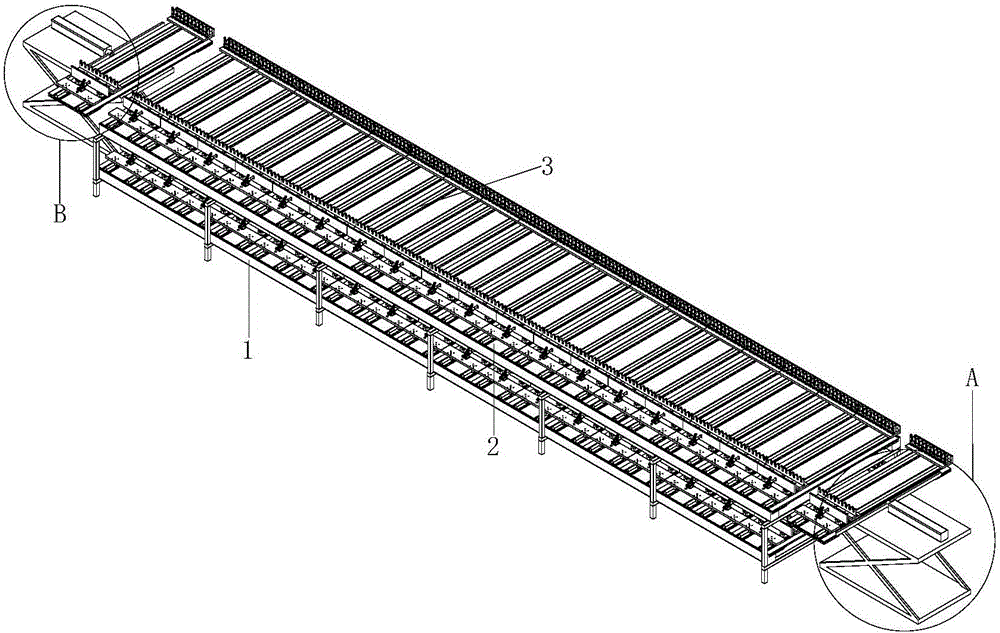

[0051] A cyclic aging device comprising a frame such as figure 1 and figure 2 As shown, the frame is provided with at least two aging platforms 1. In this embodiment, the frame specifically includes two aging platforms 1, and the aging platform 1 is provided with an aging area 2, and the upper position of the aging area 2 Also be provided with aging tooling board 3; The loading side of this frame and the unloading side are respectively provided with the first lifting mechanism 4 and the second lifting mechanism 5, and this first lifting mechanism 4 and the second lifting mechanism 5 are also respectively provided with There are a first push assembly and a second push assembly.

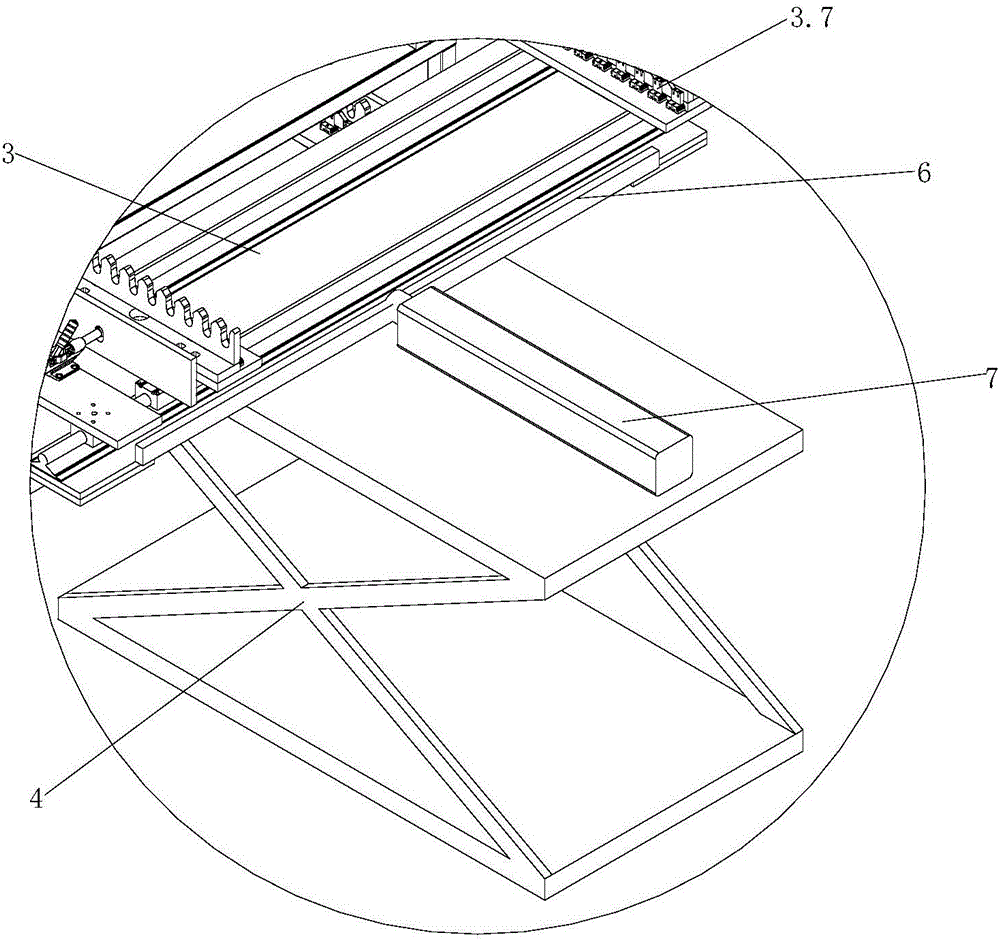

[0052] The top platform of the above-mentioned first lifting mechanism 4 is provided with a first waiting area, such as image 3 As shown, the above-mentioned first push assembly includes a first push rod 6 and a first drive mechanism 7 for driving the first push rod 6, and the first push rod 6 is p...

Embodiment 2

[0067] This embodiment provides an automatic pipeline, such as Figure 9 As shown, the automatic assembly line includes a coding assembly line 15, a cycle aging device 16, a power detection assembly line 17, a packaging assembly line 18 and a robot 19, wherein the structure of the cycle aging device 16 is the same as the structure of the cycle aging device provided in Example 1 .

[0068] Because the structure of the cyclic aging device 16 is the same as that of the cyclic aging device provided in Embodiment 1, the automatic assembly line provided in this embodiment also has the advantages of avoiding lamp falling, low aging cost, high aging efficiency, and can ensure consistent installation of lamps. The advantages of security can also reduce the floor space to a certain extent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com