Carbon fiber electric heating temperature controller

A carbon fiber, thermostat technology, applied in temperature control, non-electric variable control, instruments, etc., can solve the problems of low efficiency and high noise, and achieve the effects of increased power, simple and common materials, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

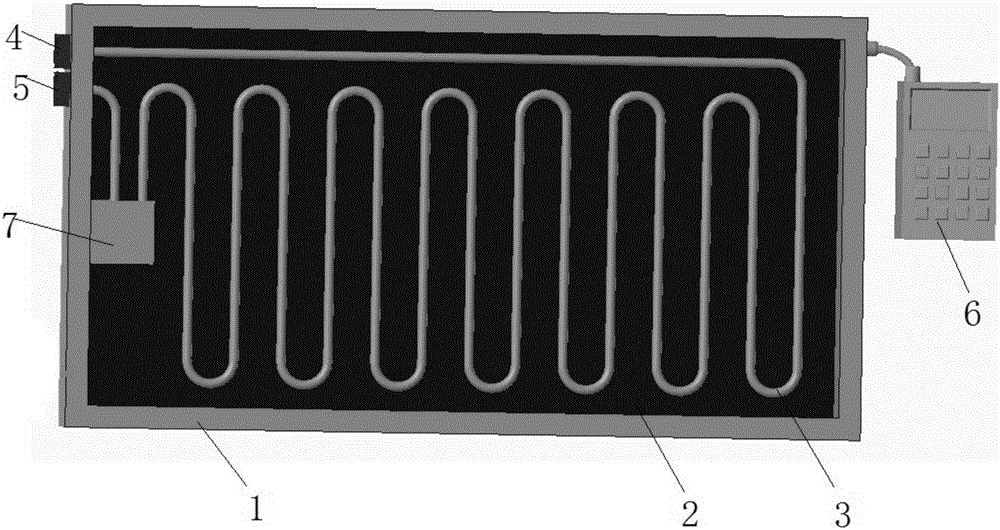

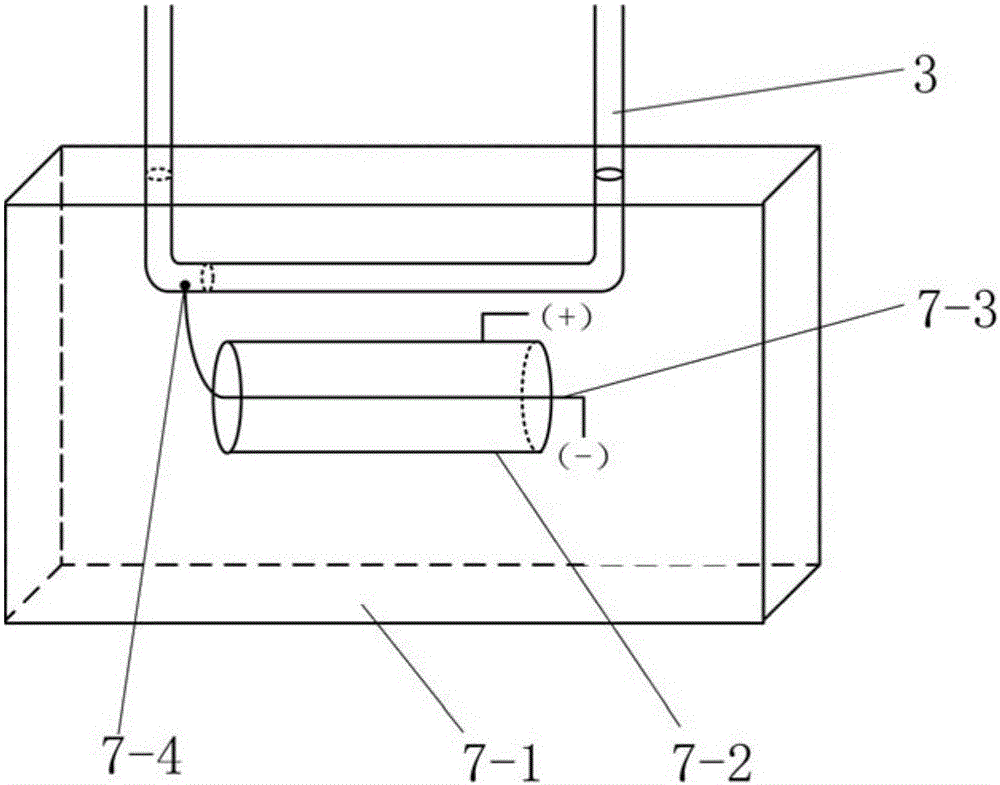

[0028] The present invention provides a carbon fiber electric thermostat, comprising a wall-mounted heating body 1 and a temperature control device 6, wherein: the wall-mounted heating body 1 includes a thermal insulation layer 2, a convection layer, a heating layer and a decorative layer arranged in sequence; For connection with the wall and heat insulation; the troposphere includes a cavity, the cavity is provided with an air inlet 4 and an air outlet 5 on the side, the air inlet 4 is provided with a fan, and the cavity is provided with a heat pipe 3 that is close to the heating layer , the two ends of the heat pipe 3 are respectively connected to the air inlet 4 and the air outlet 5; the heating layer is formed by alternately arranging carbon fibers and metal wires; the temperature control device 6 includes a temperature sensor for obtaining the amb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com