A Multi-objective Optimal Design Method for Machine Tool Beam Based on Orthogonal Test Analysis

A multi-objective optimization and orthogonal test technology, which is applied in the field of mechanical design, can solve the problems that the optimal parameter combination scheme is not seen in the orthogonal test method, and the structural improvement measures for the weak link of the beam are not directly proposed, so as to reduce the The effect of maximum coupling deformation, less test times, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

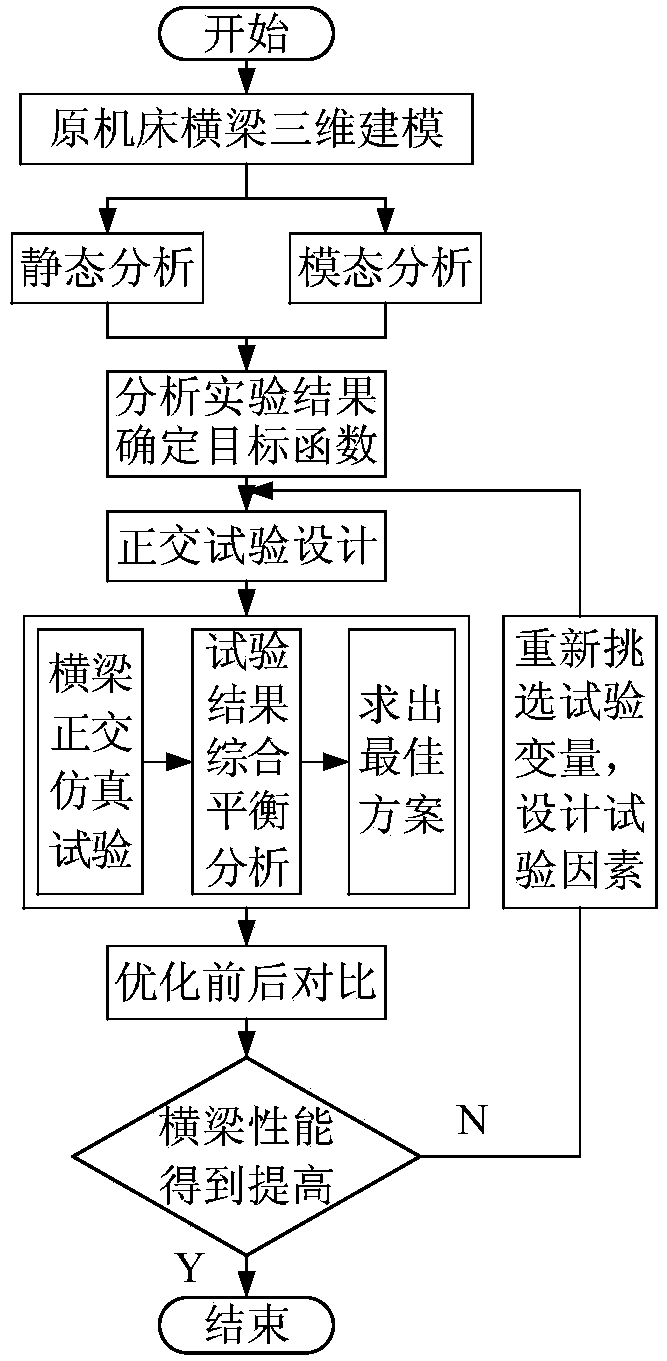

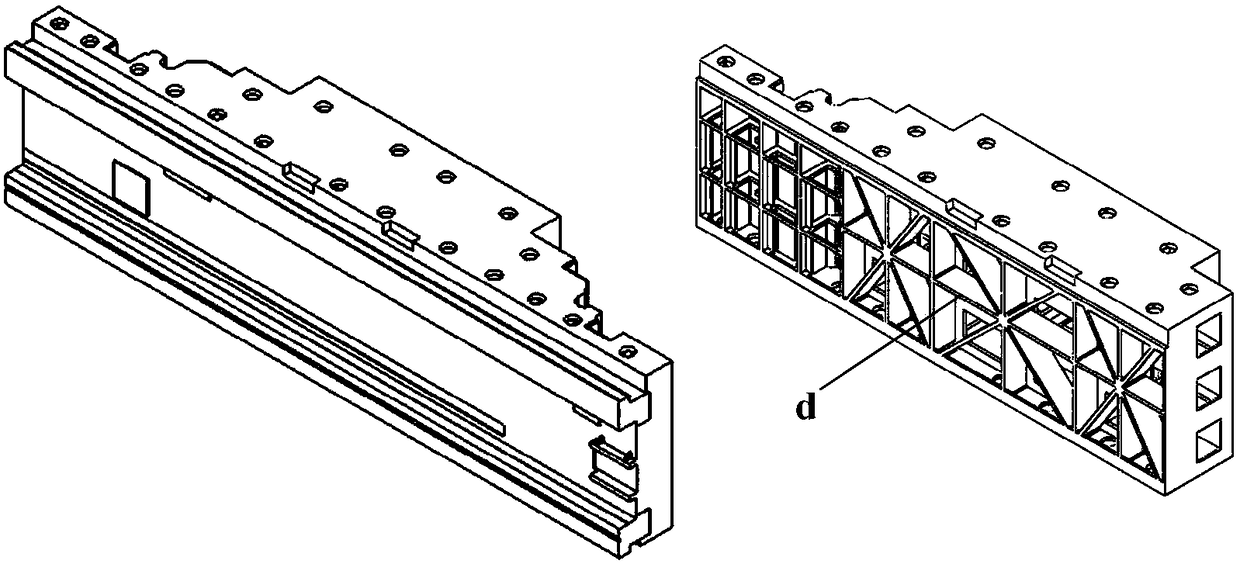

[0027] Such as figure 1 Shown is the flowchart of the method of the present invention. First, carry out three-dimensional modeling of the original moving beam, simulate the static and dynamic mechanical properties of the beam according to the actual working conditions, and analyze the simulation data to obtain the objective function of the optimal design of the beam, that is, to determine the factors that affect the performance of the beam: beam rib structure, rib Thickness, upper guide rail support rib structure, and determine the evaluation indicators for evaluating the performance of beams: beam quality, maximum coupling deformation, maximum coupling stress, and first-order natural frequency.

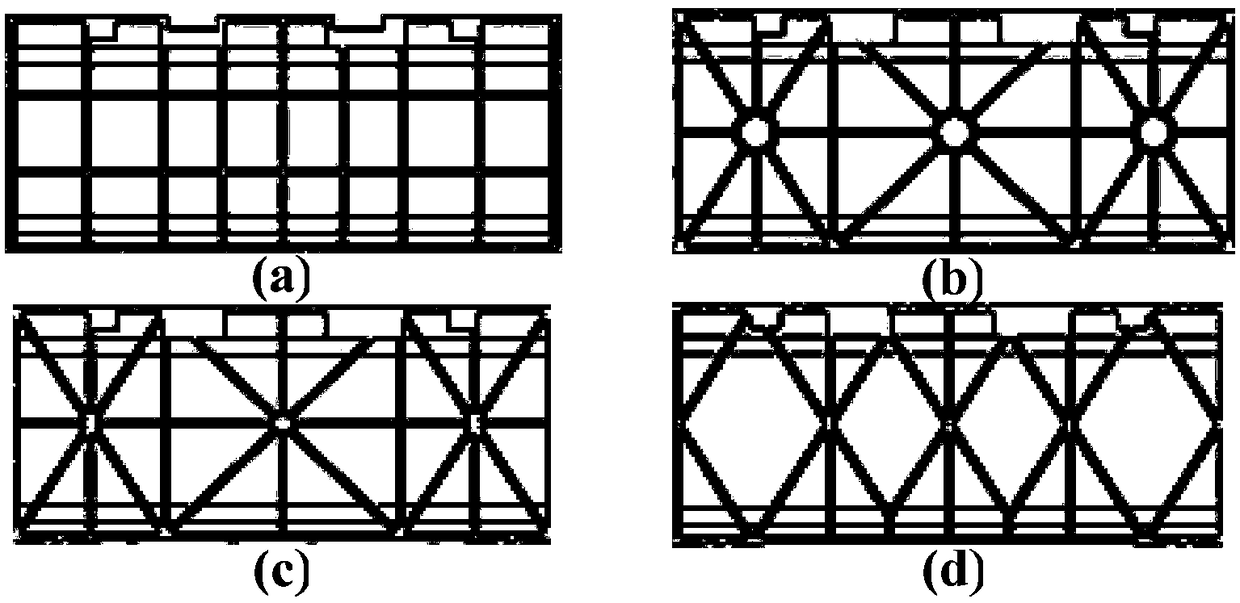

[0028] Orthogonal experimental design is then carried out: determine the experimental factors, and select the number of levels for each factor. In the present invention, the number of factors is 3, and the number of levels is 4, and an orthogonal test of three factors and four level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com