High-reliability security check ceramic X-ray tube

An X-ray tube and reliability technology, applied in X-ray tubes, X-ray tube windows, X-ray tube cooling, etc., can solve problems such as defects in the design of security inspection tubes, unreasonable electric field distribution, unreasonable structure, etc., and achieve installation It is convenient and quick to disassemble, save strategic resources and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

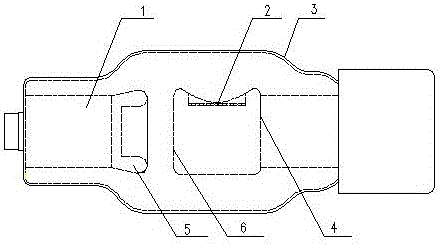

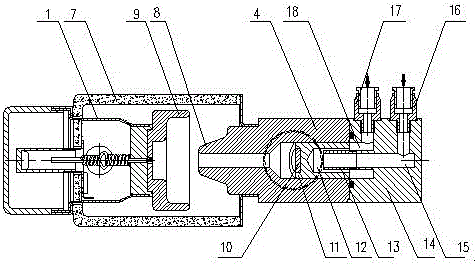

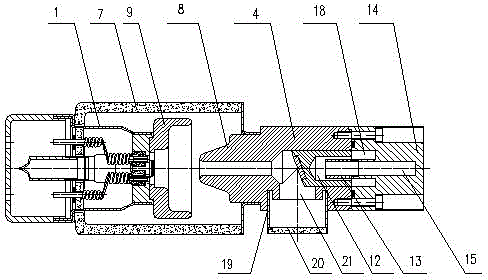

[0025] see figure 2 , 3. The present invention includes an anode assembly 4 and a cathode assembly 1. An anode head 8 in the anode assembly 4 is arranged opposite to a focusing disk 9 in the cathode assembly 1. It is characterized in that: the anode assembly 4 and the cathode assembly 1 are made of a ceramic shell 7 butt joint assembly, the anode head 8 and the focusing disk 9 are placed in the ceramic shell 7, the anode assembly 4 is provided with a radiation output window located outside the ceramic shell 7, and the anode head 8 is a conical head structure, the focusing disk 9 is provided with a small circular cavity and a large circular cavity in a hat-shaped structure, the large circular cavity is located at the outer end and arranged opposite to the anode head 8, and the inner diameter of the large circular cavity is greater than the maximum outer diameter of the anode head 8 ; A water cooling jacket is installed at the tail end of the anode head 8 .

[0026] The ray ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com