A proton exchange membrane fuel cell stack steel belt fastening device

A fuel cell stack and proton exchange membrane technology, applied in the field of proton exchange membrane fuel cell stack steel belt fastening device, can solve the problems of fuel cell performance impact, membrane electrode elasticity reduction, rotation only within a certain angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

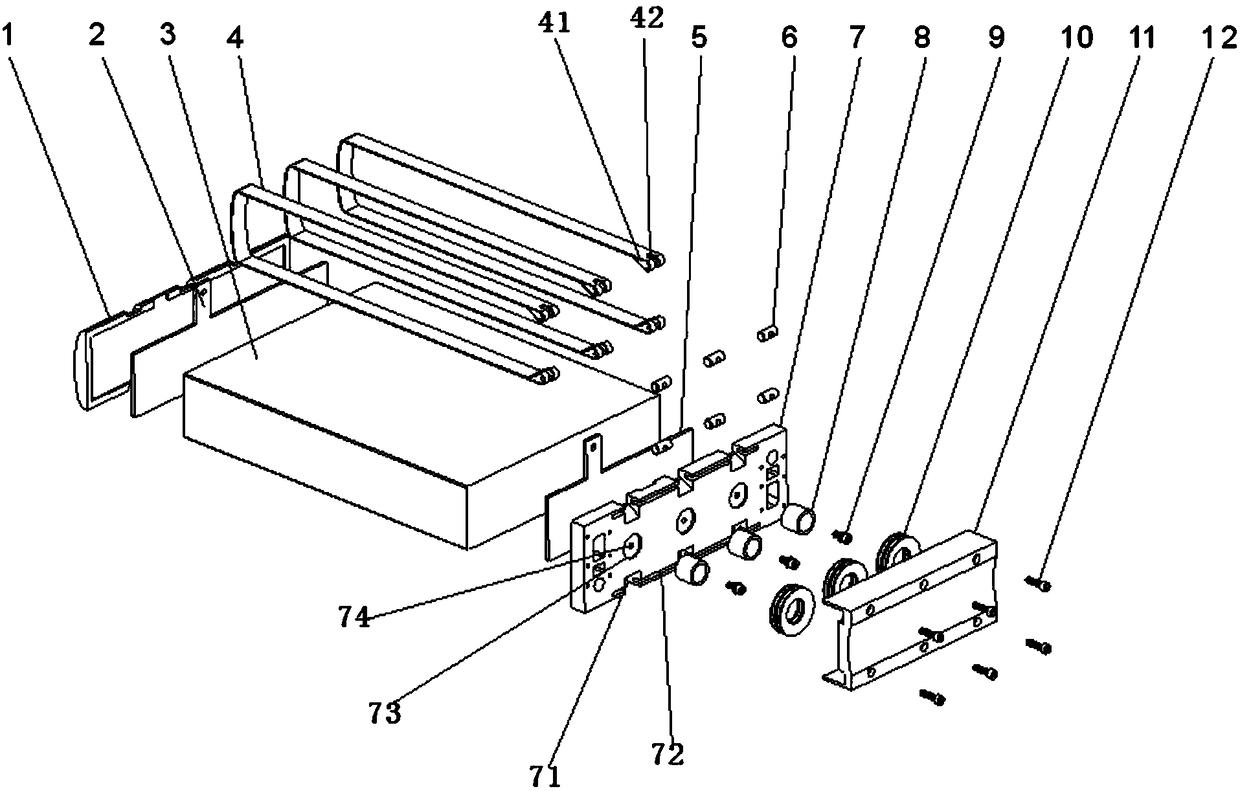

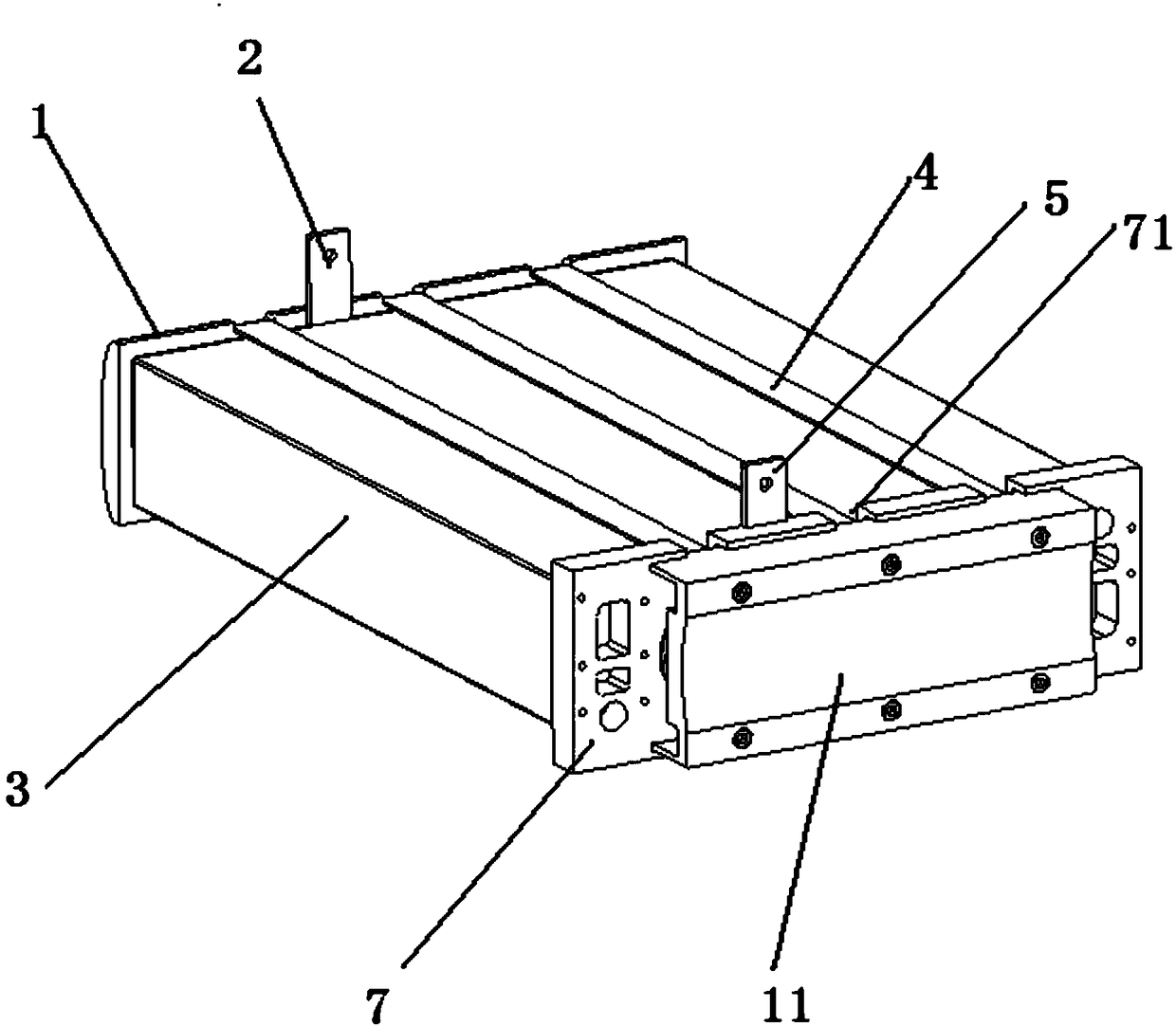

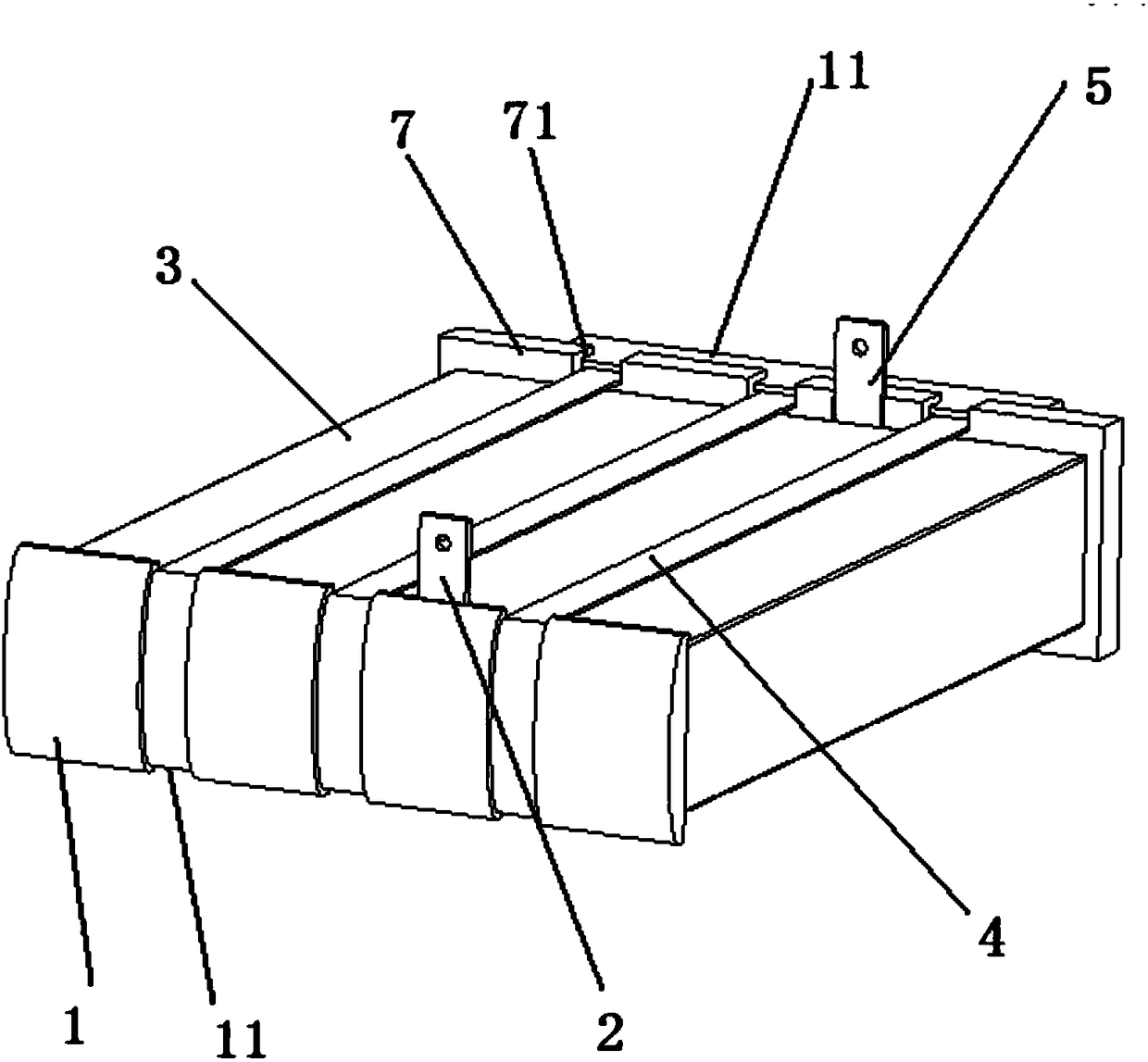

[0040] refer to Figure 1-3 As shown, this embodiment discloses a proton exchange membrane fuel cell stack steel strip fastening device, which includes in turn: a rear end plate 1, a rear end copper bar 2, a graphite plate membrane electrode group 3, and a front end copper bar 5 , front end plate 7, disc spring 10, disc spring pressure plate 11 are set on the outside of the above rear end plate 1 through steel strip 4, and the rear end plate 1, rear end copper bar 2, graphite plate membrane electrode group 3, front end copper The row 5 and the front end plate 7 are locked, and then the above-mentioned disc spring pressure plate 11 is locked and installed by the first bolt 12 .

[0041]In this embodiment, the rear end plate 1 is used as the rear end of the device, the front end plate 1 is used as the front end of the device, and the graphite plate membrane electrode group 3 is the main part of the battery stack.

[0042] Specifically, the above-mentioned steel strip 4 has a U-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com