Rotor dual-side permanent-magnet type single-winding dual-stator vernier motor

A vernier motor, single-winding technology, used in motors, magnetic circuits, electromechanical devices, etc., can solve the problems of low utilization rate of permanent magnets and small output torque, and achieve high utilization rate of stator slots, increased torque output capability, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

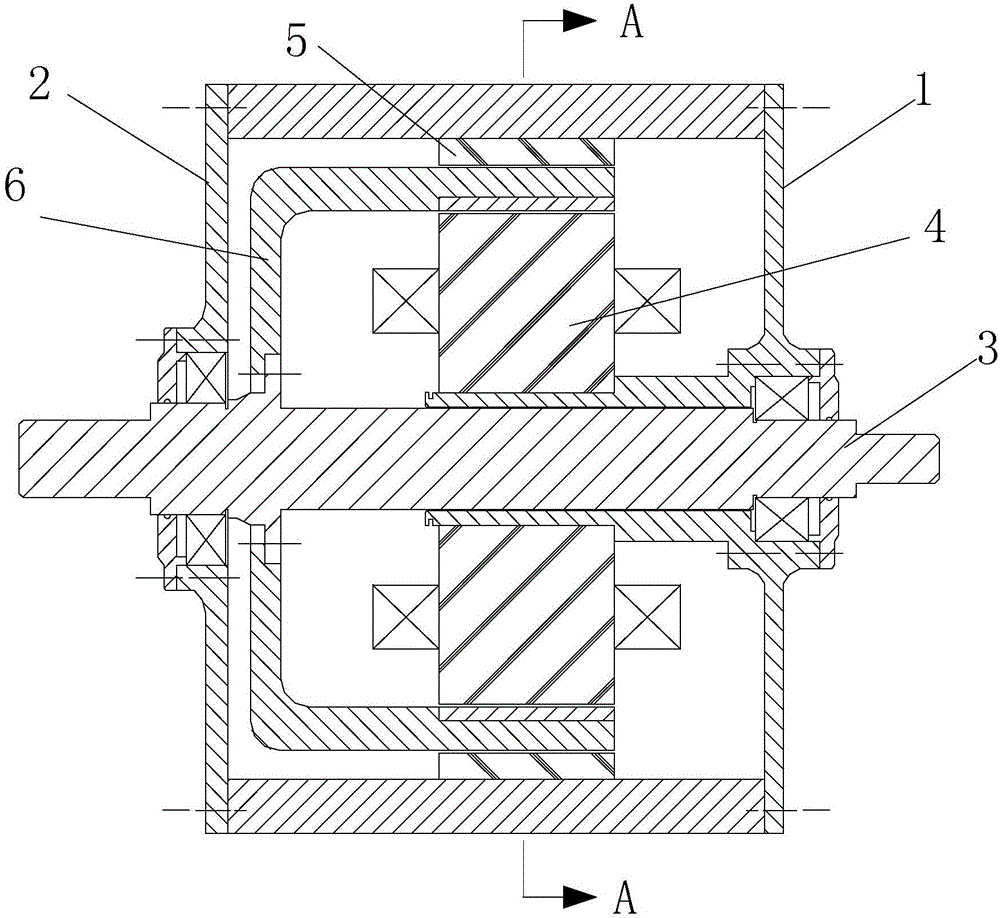

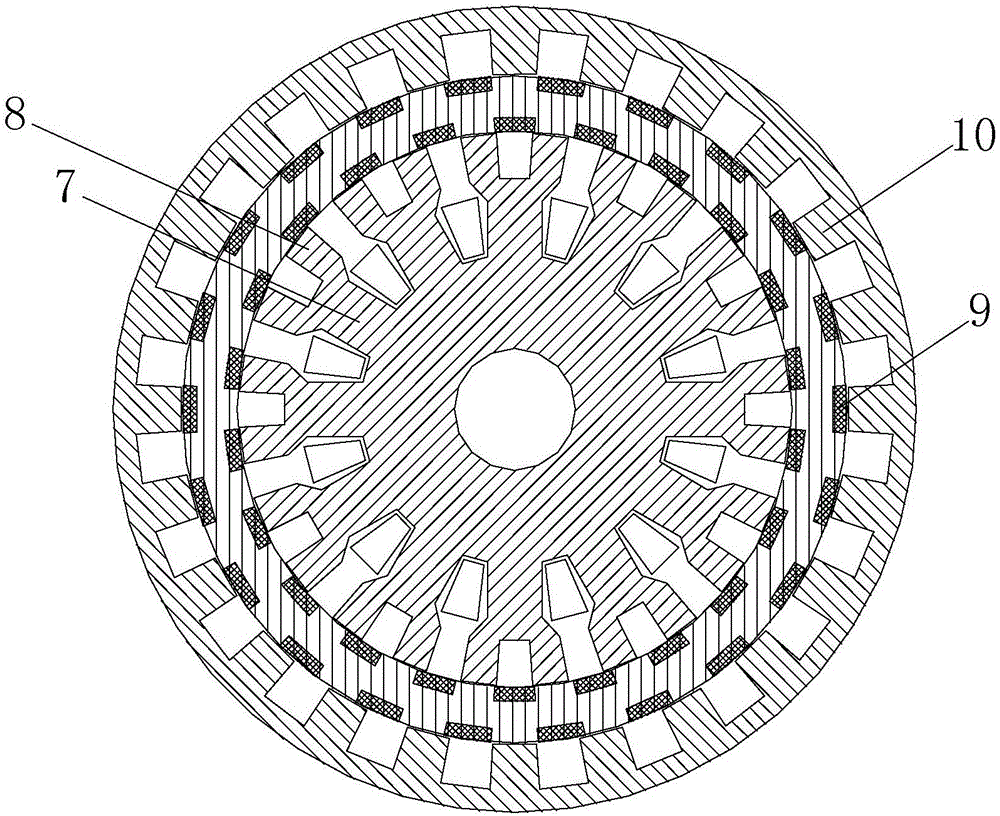

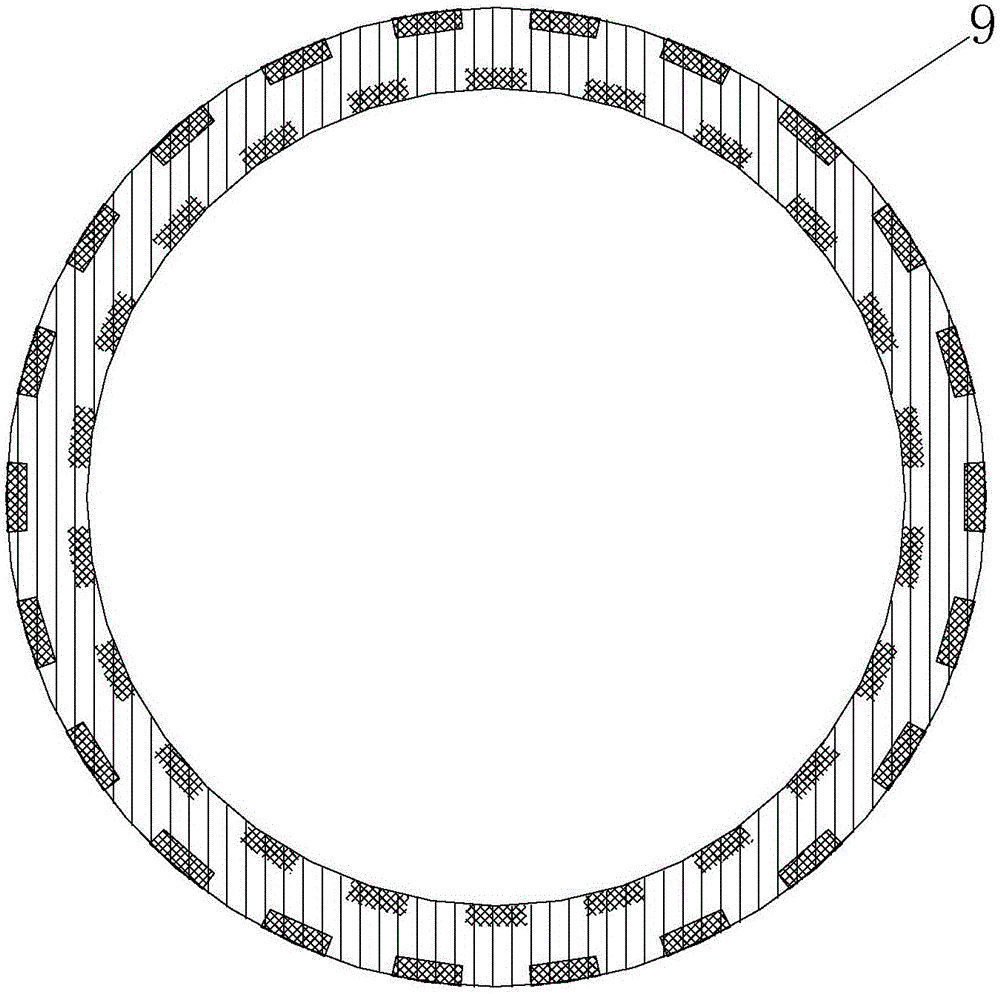

[0016] Specific implementation mode 1. Combination Figure 1 to Figure 3 Describe this specific embodiment, the rotor double-sided permanent magnet type single-winding double-stator vernier motor described in this specific embodiment includes an inner stator 4, an outer stator 5, a rotor 6, a rotor output shaft 3, a left end cover 2 and a right end cover 1. The inner end of the inner stator 4 is fixedly connected with the right end cover 1, and the rotor output shaft 3 is arranged in the center hole of the right end cover 1, and one end of the rotor output shaft 3 is supported in the inner hole of the left end cover 2 through a bearing, and the rotor output shaft 3 The other end of the rotor is supported in the inner hole of the right end cover 1 through a bearing. The rotor 6 is a cup-shaped rotor. The cup bottom of the rotor 6 is fixedly connected with the rotor output shaft 3. The cup body of the rotor 6 is located between the inner stator 4 and the outer stator 5. Between,...

specific Embodiment approach 2

[0024] Embodiment 2. The difference between this embodiment and the permanent-magnet double-rotor single-winding double-stator vernier motor described in Embodiment 1 is that the N is 12.

specific Embodiment approach 3

[0025] Embodiment 3. The difference between this embodiment and the double-sided permanent magnet single-winding double-stator vernier motor described in Embodiment 1 is that the permanent magnet 9 embedded in the rotor 6 is a sintered NdFeB magnet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com