Subsoiling rotary plow

A plowing and subsoiling technology, applied in the field of subsoiling rotary plowing, can solve the problems of low work efficiency, low seedling emergence rate, uneven fertilizer nutrient, etc., and achieve the effect of high work efficiency, soft soil and good moisture retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

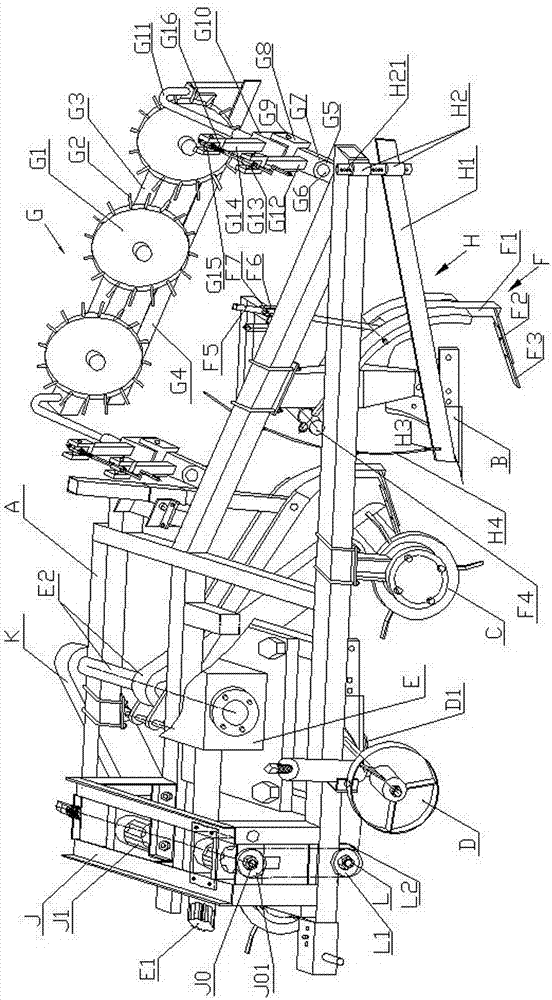

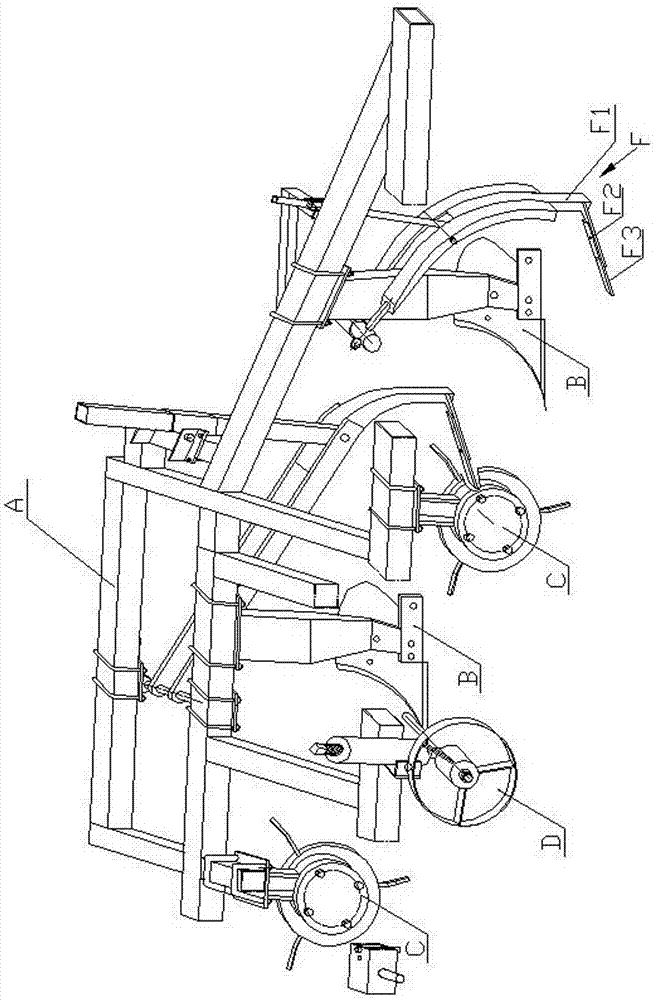

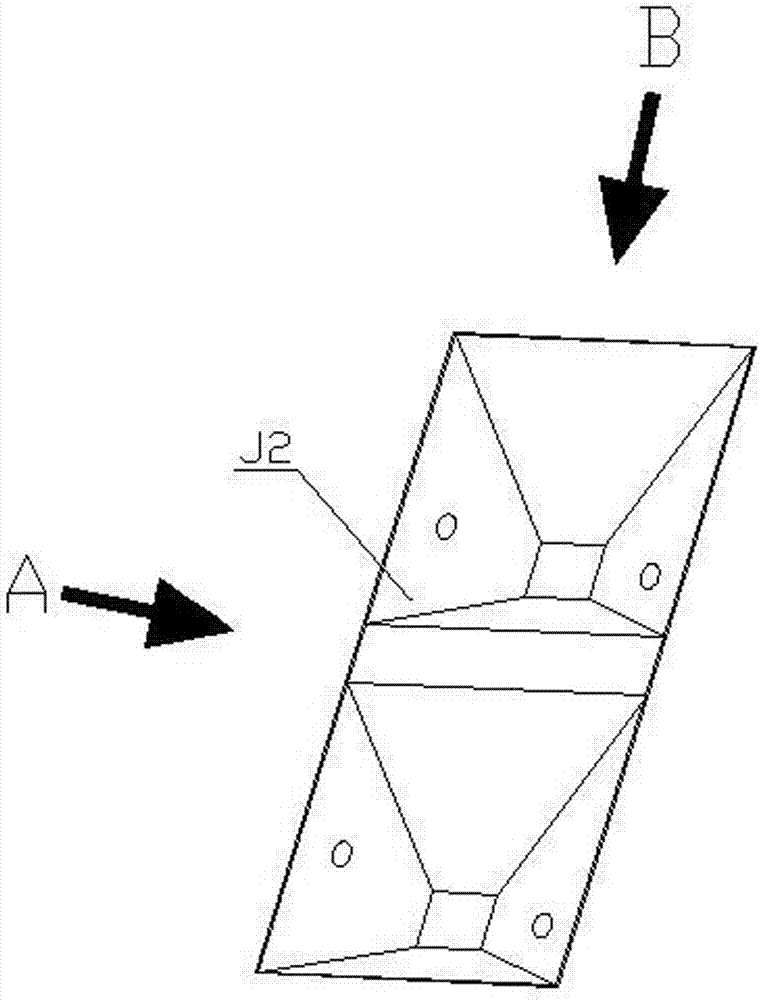

[0021] As shown in the figure, the subsoiling rotary plow is composed of a plow frame A, a plow share B and a rotary plow C. The plow share B is installed on the plow frame A. The rotary tiller is an "L"-shaped single-direction soil-throwing rotary knife, the throwing direction of the rotary plow C is the same as that of the plowshare B, and the width of the rotary plow C is the same as that of the plowshare B. , the rotary tillage depth of the rotary plow C is less than the plowing depth of the plowshare B, a gearbox E is installed on the upper part of the plow frame A, the input shaft E1 of the gearbox E is connected with the tail shaft of the tractor, and the output shaft of the gearbox E The shaft E2 is provided with a rotary tillage driving sprocket E21, and the number of the rotary tillage driving sprocket E21 is the same as that of the rotary tillage plow C, and the rotary tillage driven sprocket C11 is arranged on the shaft of the rotary tillage plow C. The tillage dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com