An independent circulating aquaculture system with separation of aquaculture water and solid waste

A solid waste and circulating aquaculture technology, which is applied in the direction of centrifugal separation water/sewage treatment, biological water/sewage treatment, light water/sewage treatment, etc., can solve the problems of easy cross-infection and high cost, and reduce the probability of foreign pathogens , to prevent the effect of cross-infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

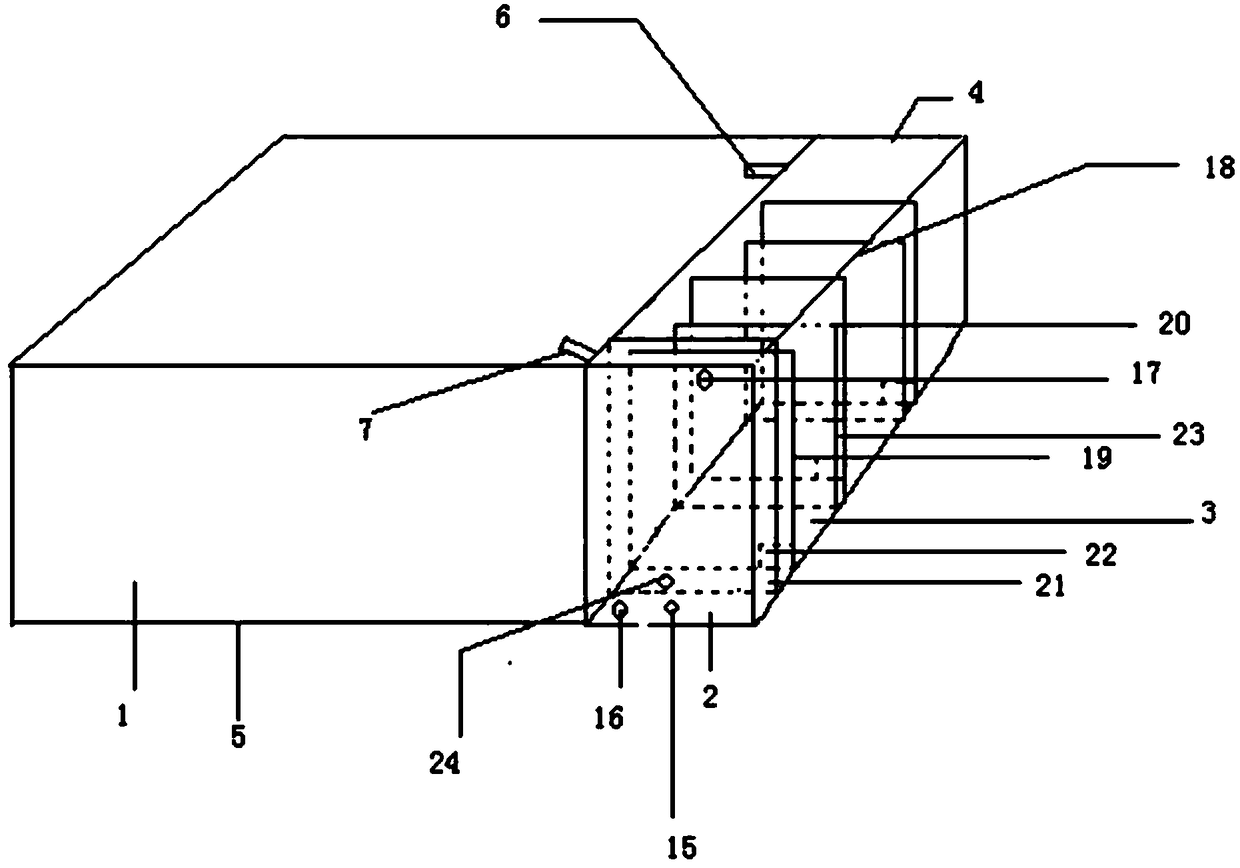

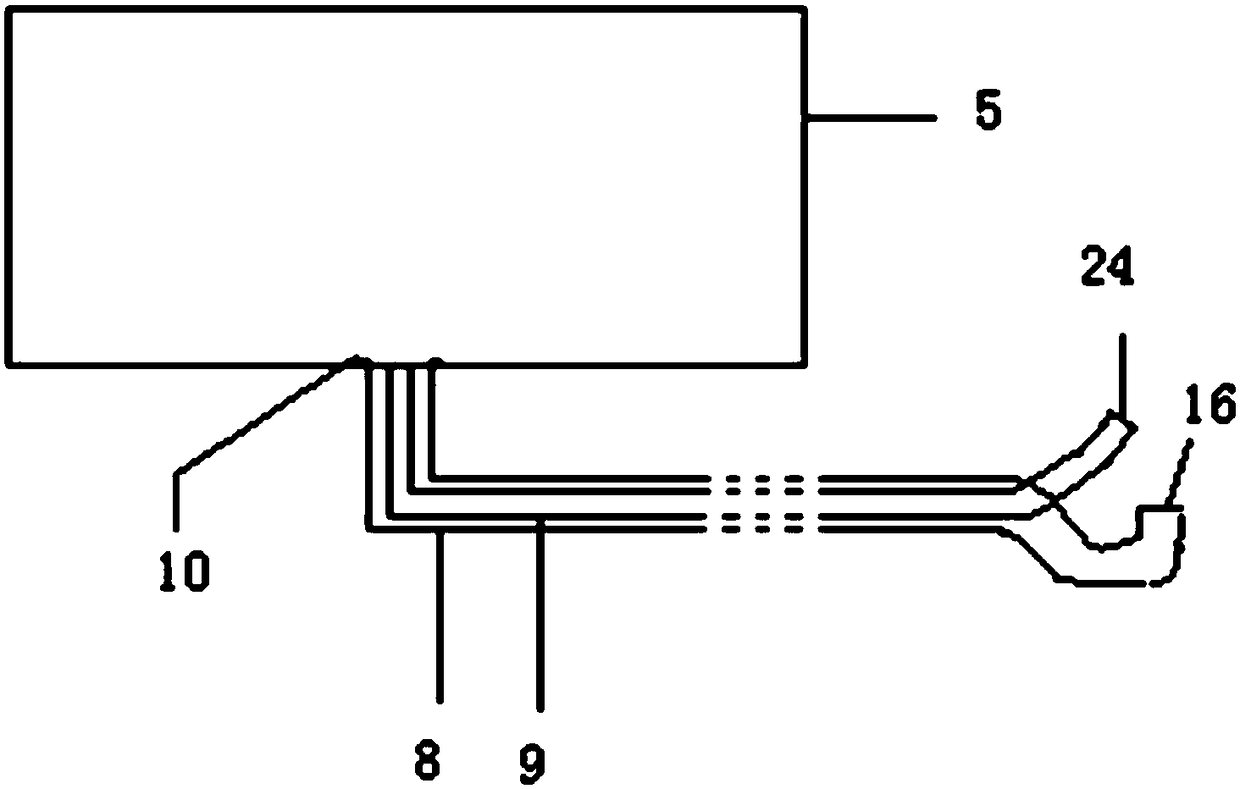

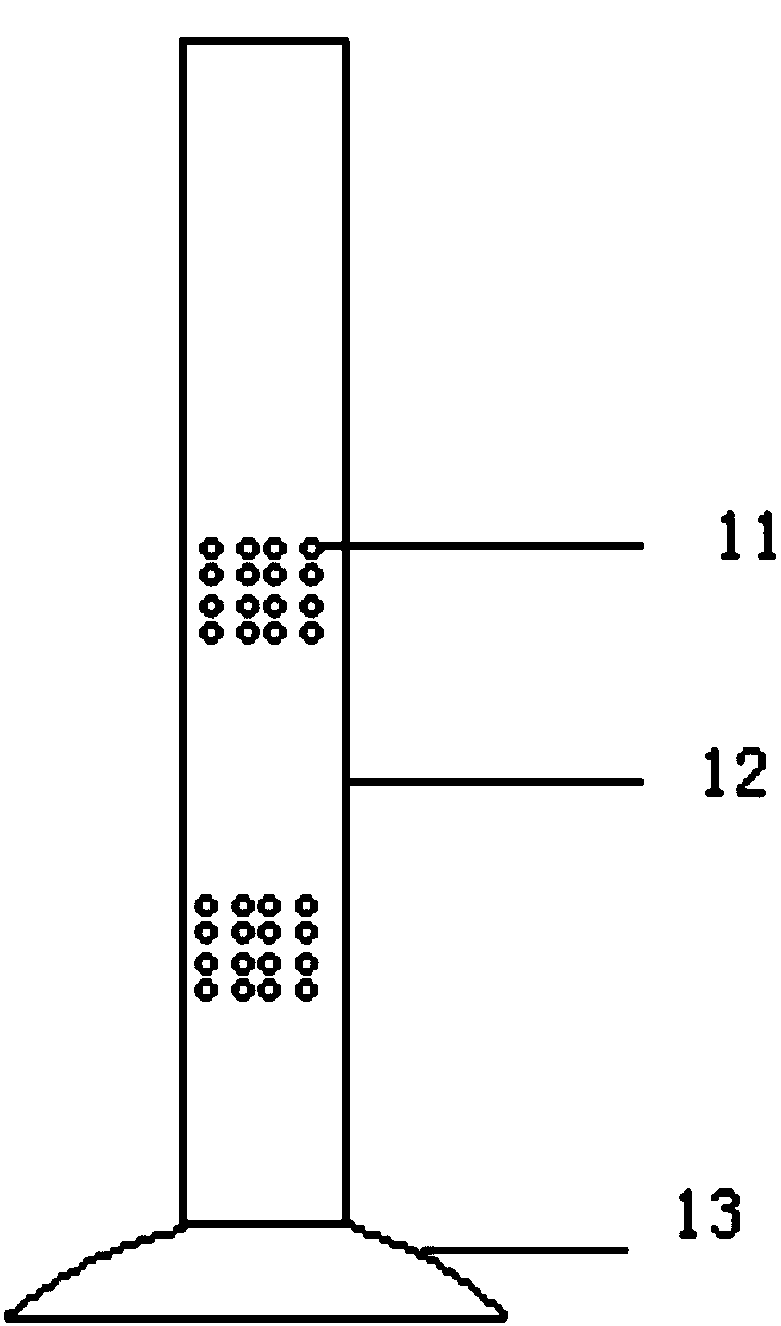

[0023] An independent circulating aquaculture system that separates aquaculture water and solid waste, such as figure 1 , 2 Shown in and 3, it comprises cultivation unit 1, particulate matter separation unit 2, biological treatment unit 3, ultraviolet sterilizing unit 4, and described cultivation unit comprises cultivation pond 5, water inlet pipe 6, water level control pipe 7, particulate matter discharge pipe 8, Clear water discharge pipe 9, ring 10 and water filter pipe, the mouth of described water inlet pipe is positioned at the top of culture pond, and water level control pipe comprises horizontal straight pipe, free turning elbow and diversion pipe, and one end of described horizontal straight pipe communicates with Biological treatment unit, the other end is connected to the culture tank. The opening of the horizontal straight pipe in the culture tank is higher than the nozzle of the water inlet pipe. One end of the steering elbow is connected to the horizontal straigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

| oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com