High-strength inner pot and electric heating pot using the inner pot

A high-strength, pot liner technology, used in applications, kitchen utensils, home utensils, etc., can solve the problems of high radian requirements of spherical liner, affecting appearance and performance, unstable mold forming size, etc., to achieve novel appearance, Easy processing and the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

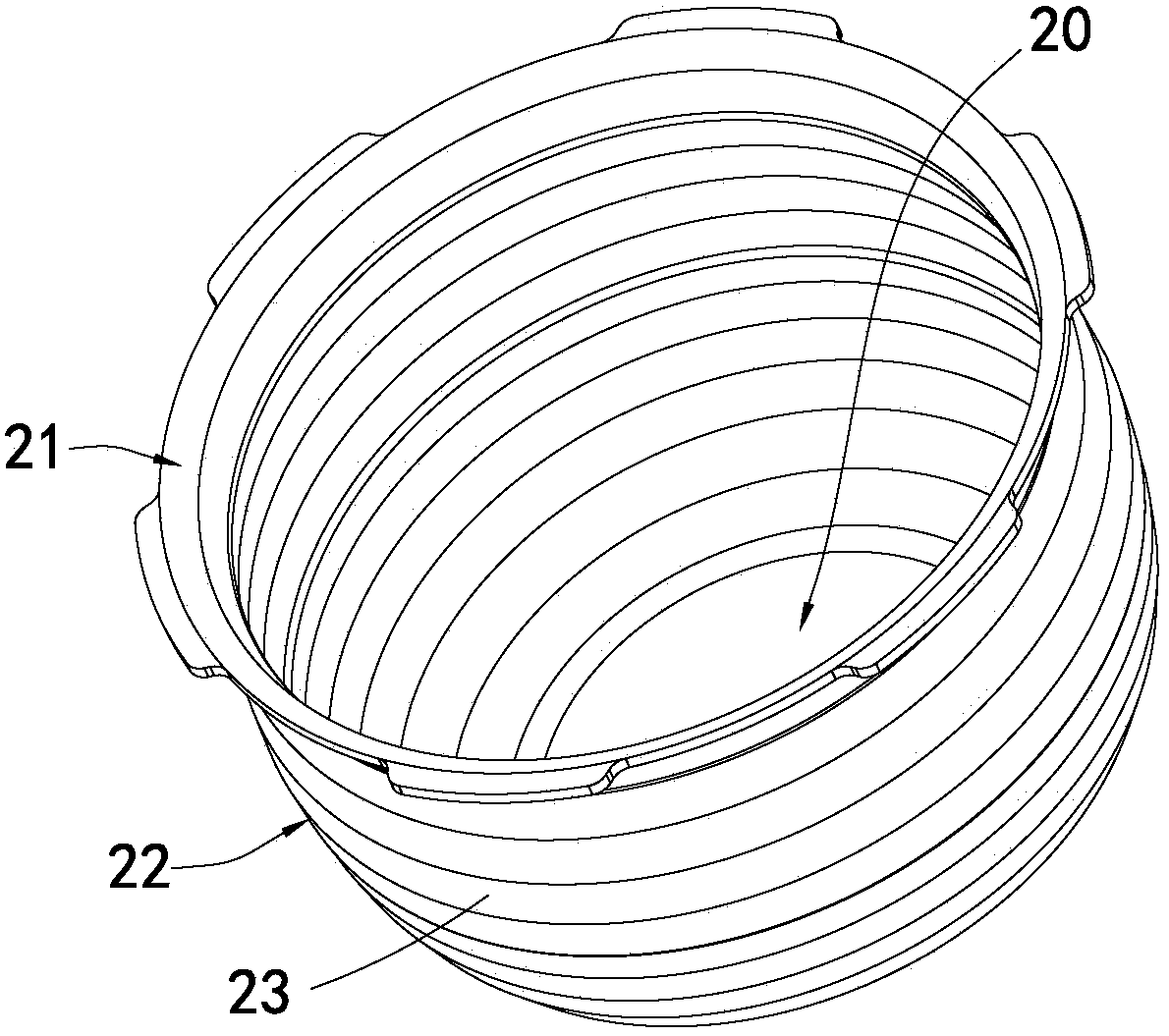

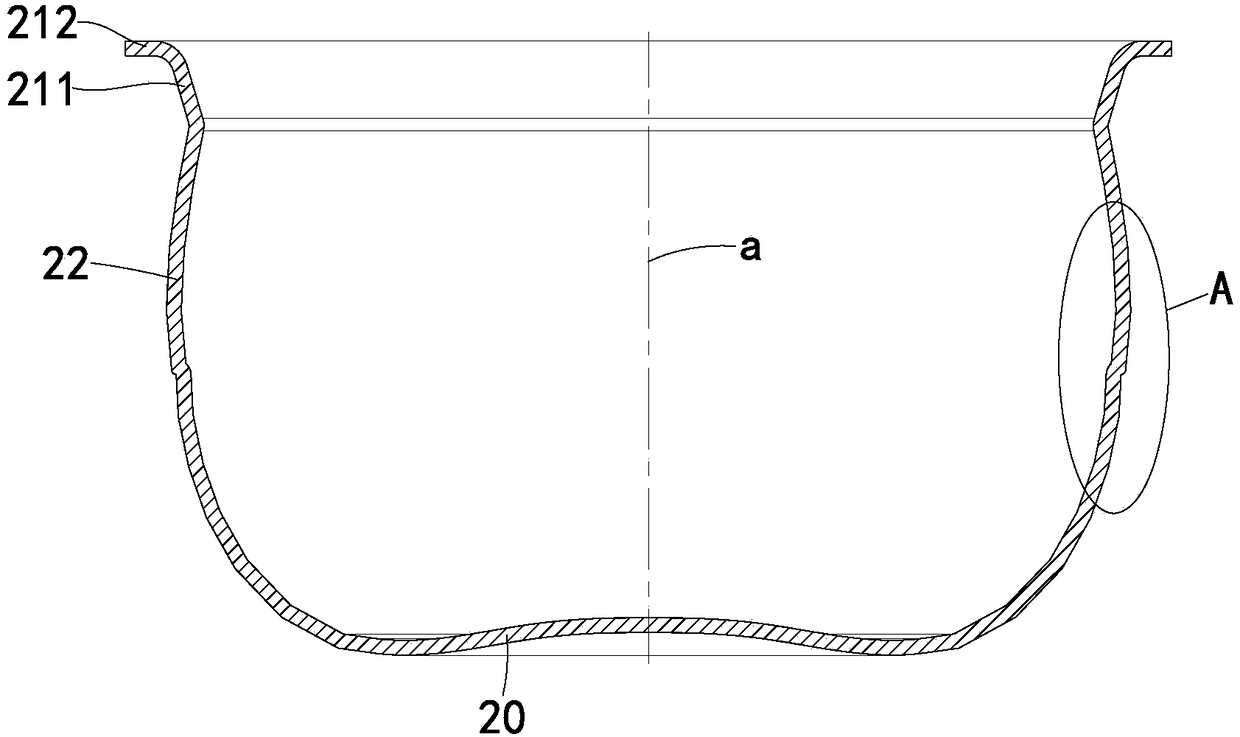

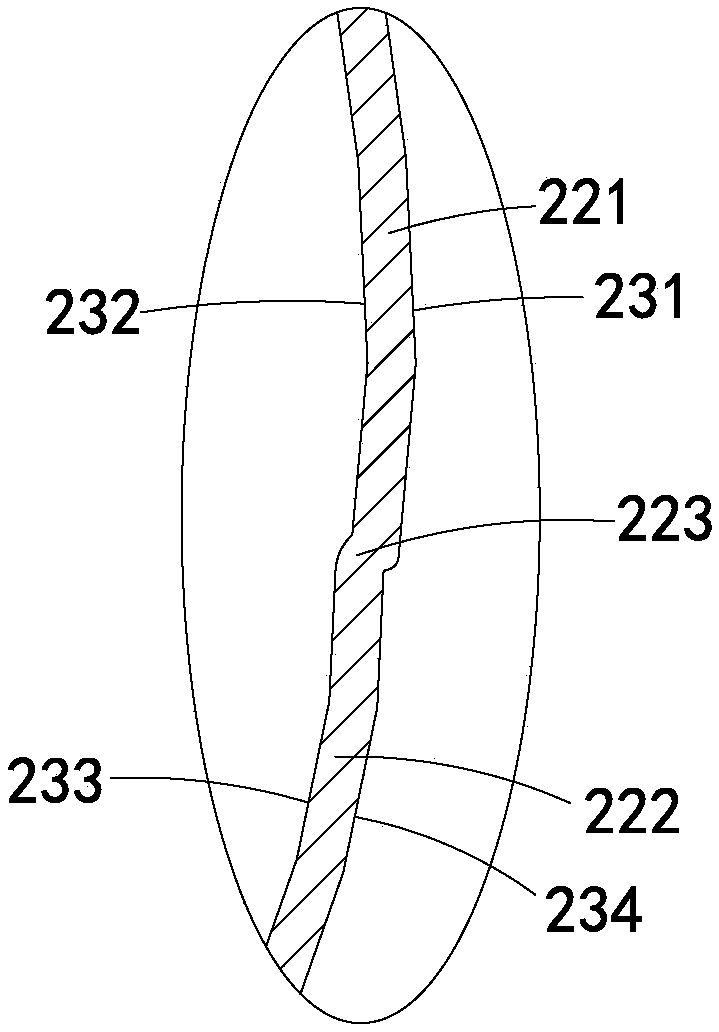

[0031] refer to figure 1 , the high-strength pot liner proposed in Embodiment 1 of the present invention includes a liner bottom 20, a liner body 22 and an opening 21, wherein the liner bottom 20 is arranged at the bottom of the liner body 22 and is a plane or a curved surface with a certain radian, and the opening 21 is located on the upper part of the bladder body 22, and the opening 21 generally includes a flange 212 and a smooth portion 211 connecting the flange 212 and the bladder body 22. The smooth portion 211 is in the shape of a neck, and the bladder body 22 is respectively extended from its largest diameter to The bottom 20 of the bladder and the opening 21 taper, and the structure of the existing spherical inner tank is roughly the same. The difference of this embodiment is that the entire outer surface and the entire inner surface of the bladder body 22 are formed by several circles of straight wall sections 23 along the inner surface of the bladder. The height dir...

Embodiment 2

[0043] refer to Figure 4 , 5 , this embodiment is improved on the basis of Embodiment 1, further enhances the strength of the inner pot, and enriches the outer appearance of the inner pot. The planes 235 are sequentially connected to form a predetermined angle between adjacent planes 235 . Referring to the principle of implementation 1, in this embodiment, the plane 235 can decompose part of the external force and reduce the force directed to the center of the inner pot, thereby improving the anti-deformation ability of the inner pot; the predetermined angle formed between adjacent planes 235, Two adjacent planes 235 have the effect of supporting each other and share the force. Since the bladder body 22 is distributed with a plurality of such plane 235 support structures in the circumferential direction, the deformation resistance of the bladder body 22 in the circumferential direction is improved.

[0044] Preferably: the central angle b corresponding to the plane 235 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com