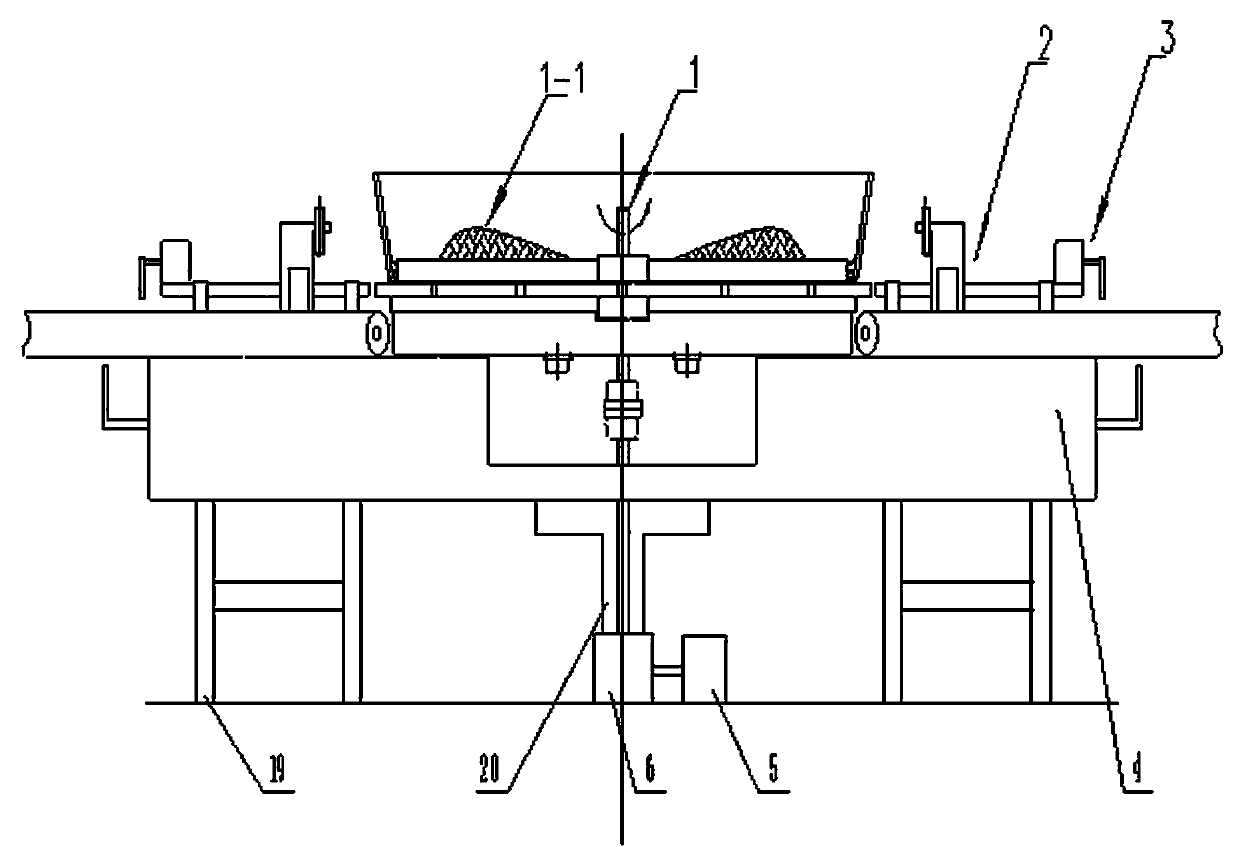

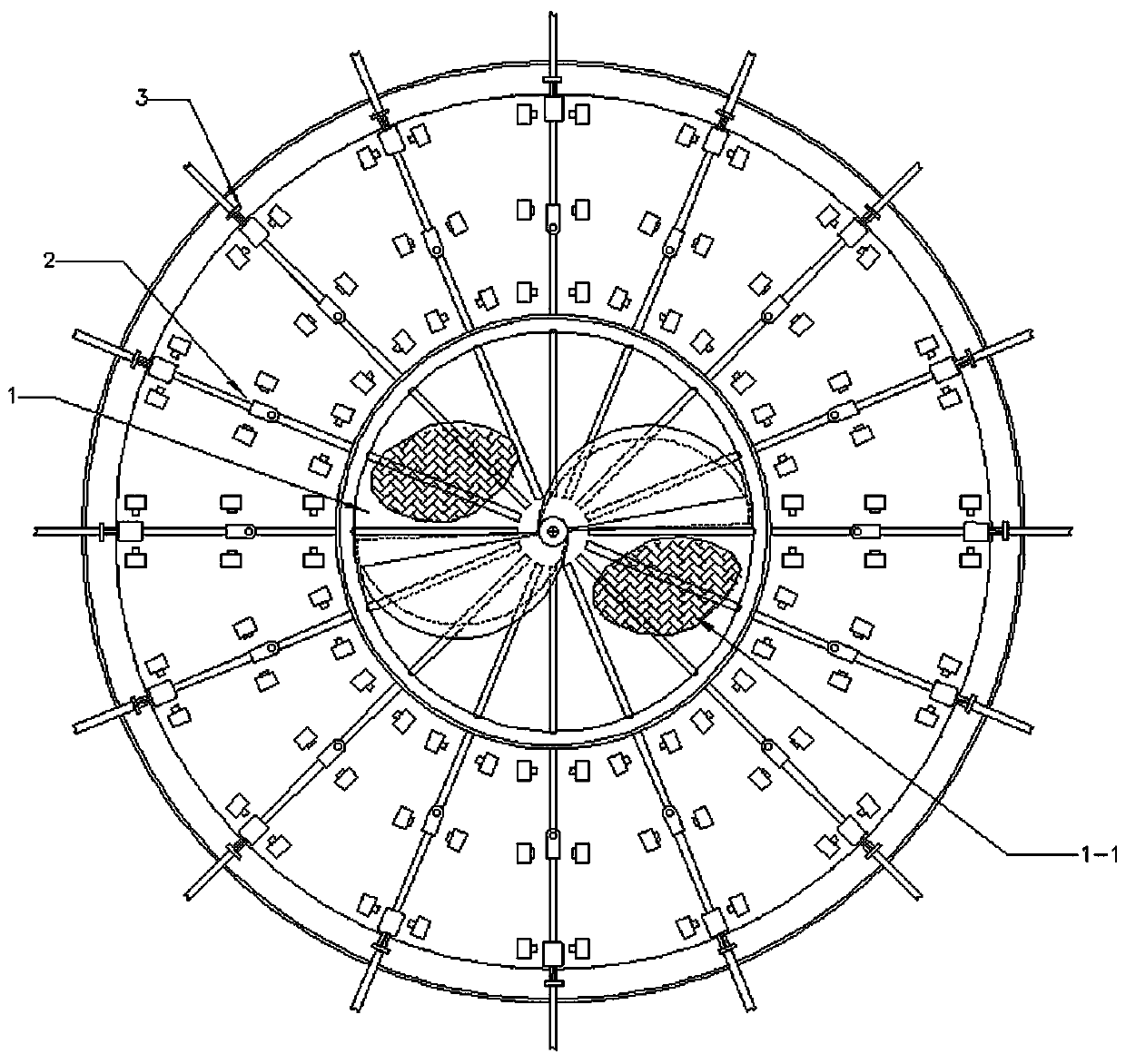

An integrated detection mechanism for detection, sorting and sorting of chip components

A detection mechanism and component technology, which is applied in the field of chip component detection and sorting integrated detection mechanism, can solve the problems of low detection efficiency, occupying time, non-stop, etc., and achieve the effects of improving detection efficiency, comprehensive judgment, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

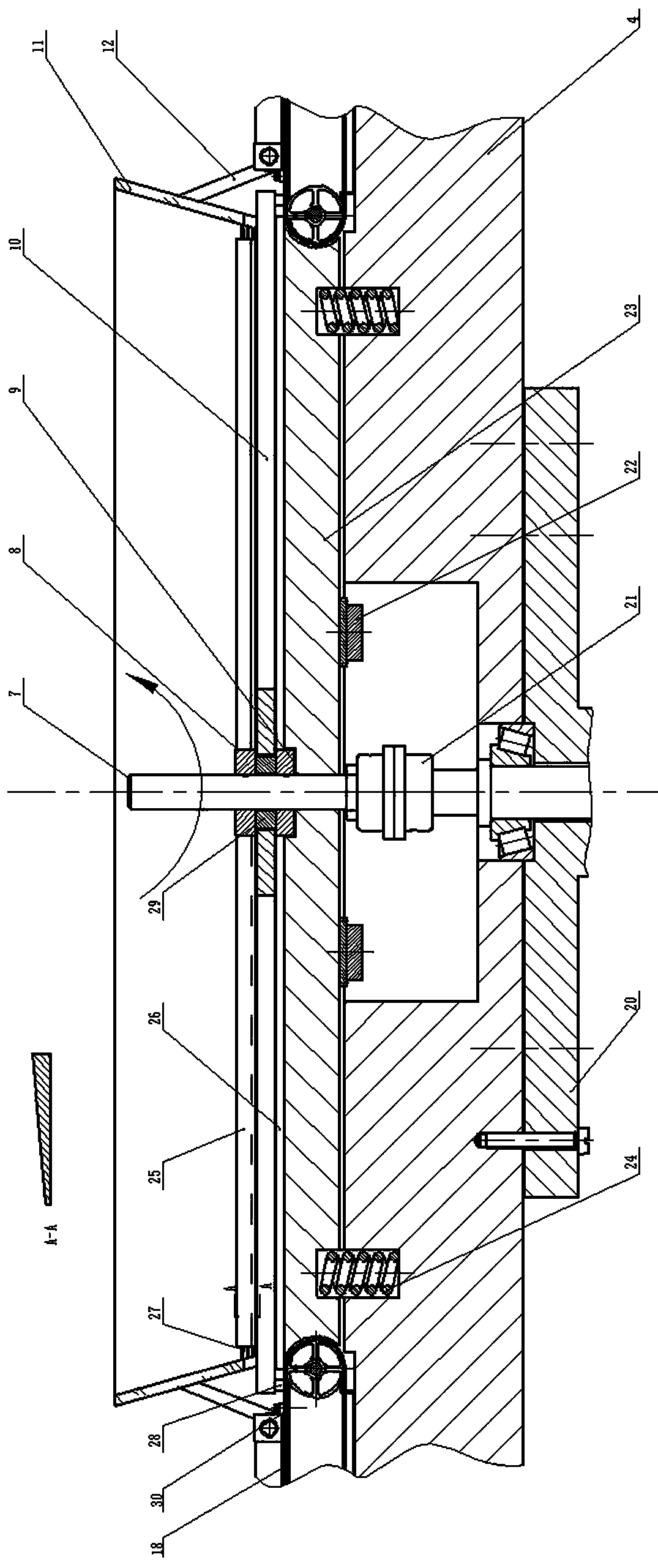

[0049] Such as Figure 7 , 8 As shown in 11 and 11, embodiment 2 is basically the same as embodiment 1, only the end of the outer layer detection mechanism and the screening mechanism are different, and only the differences are described here.

[0050] The conveyor belt 49 is completely positioned on the base 4, and its end (outside end) protrudes slightly from the outer edge of the base 4. Simultaneously, the beating mechanism of present embodiment screening mechanism 3 hangs on the outside of conveyer belt 18 ends.

[0051] The output shaft of the screening motor 16 is connected to the eccentric wheel 43, the eccentric wheel overcoat has a connecting rod 44, the connecting rod 44 is connected to the striking rod 45, and the striking rod 45 is a rectangular frame, the lower surface of which is the striking part, and the left and right sides are Embedded in the striking slot 46, it can move vertically along the slot 46.

[0052] When the component is delivered to the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com