Molding structure for green sand mold casting

A casting model and green sand technology, applied in casting molding equipment, casting molds, cores, etc., can solve the problems of large one-time investment and high cost of coated sand, and achieve high-strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

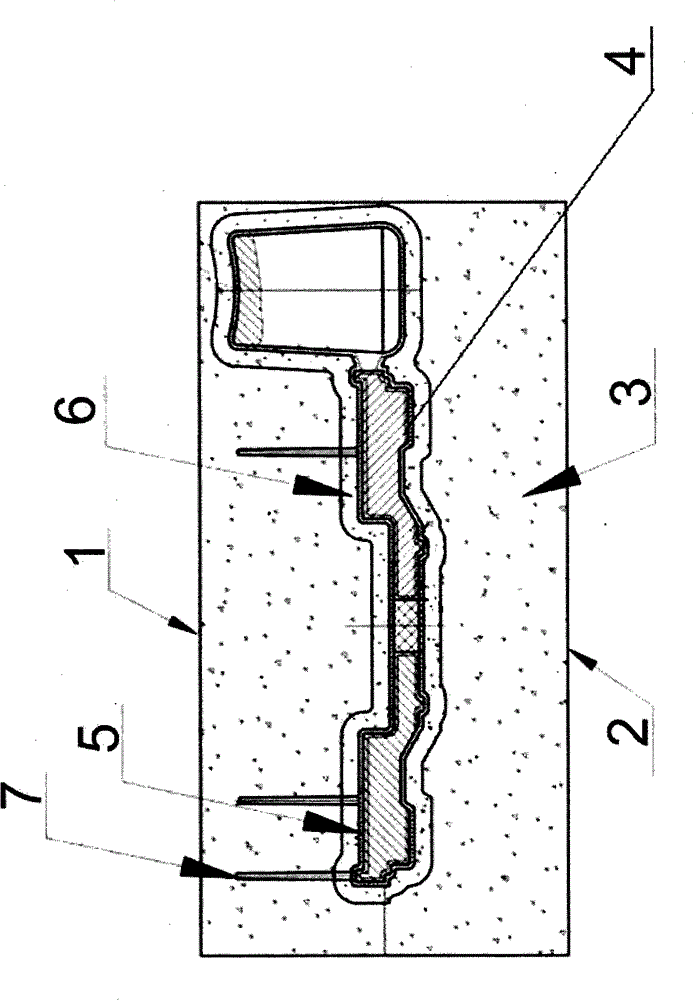

[0015] Such as figure 1 As shown, a green sand casting molding structure includes an upper box type 1, a lower box type 2, a back sand 3 is placed at the bottom of the lower box type 2, and a casting model 4 is built in the middle between the upper box type 1 and the lower box type 2, The casting model 4 is covered with coated sand 5 around, and the upper part of the coated sand 5 in the upper box type 1 is provided with surface sand 6 . The thickness of the coated sand 5 is 3-4mm.

[0016] Molding sand material preparation:

[0017] (1) Back sand 3: The sand mixing process is the same as the traditional wet sand process.

[0018] (2) Surface sand 6: The sand mixing process is the same as the traditional wet sand process.

[0019] (3) Mixing coated sand 5: mix coated sand 5 with water and bentonite as binder.

[0020] Preparation method:

[0021] Add 8% bentonite and 4.5% water to the coated sand supplied in the market by weight (coated sand 87.5%), and mix coated sand 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com