Device and method for detecting working state of nozzles in continuous-casting secondary cooling area in real time

A working state, real-time detection technology, applied in the field of continuous casting production in the metallurgical industry, can solve the problems of difficulty in judging whether it is blocked, the size of the instrument is large, and the comparison is not obvious, so as to improve efficiency and accuracy, ensure accuracy, and work life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

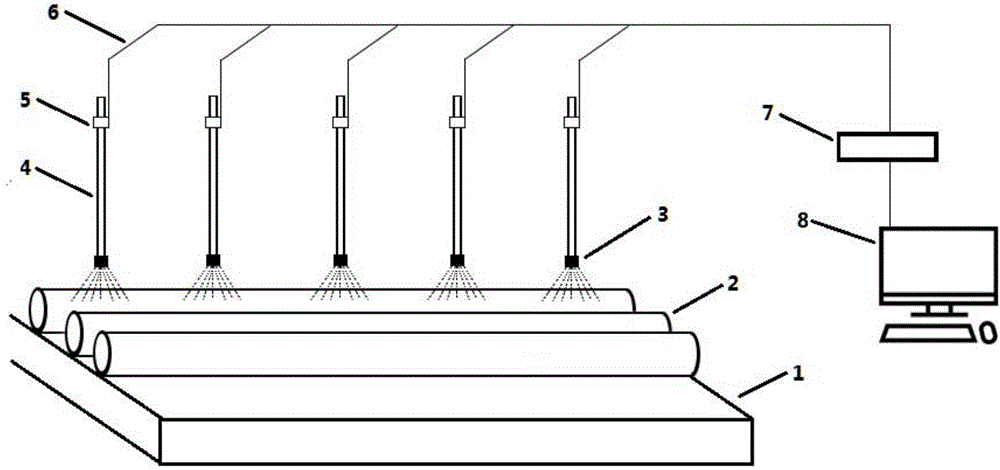

[0046] In this embodiment, the continuous casting machine is a slab continuous casting machine, the casting section is 230×1800mm, and the secondary cooling section is composed of 15 sector sections and 968 nozzles 3 in total. combine figure 1 The slab 1 passes through the secondary cooling zone of continuous casting under the support and guidance of the guide roller 2. The real-time detection device for the working state of the nozzles in the secondary cooling zone of continuous casting in this embodiment includes nozzles 3 and nozzles communicated with each nozzle 3 respectively. Vibration detectors are installed on the pipeline 4 , on the nozzle 3 or on the nozzle pipeline 4 or on other parts that are only connected with the nozzle 3 . The vibration detector is used to detect the vibration data that occurs on the nozzle 3 when the cooling medium is sprayed out of the nozzle 3. In theory, the vibration detector can measure the vibration that occurs on the nozzle 3 as long as...

Embodiment 2

[0060] The real-time detection device for the working state of the nozzle in the second cooling zone of continuous casting in this embodiment has basically the same structure as that of Embodiment 1, except that the heat insulation box 5 is installed on the outside of the nozzle pipeline 4 above the nozzle 3, at a distance from the nozzle 250mm at the top of the pipeline 4; the heat insulation box 5 is 5mm long, 30mm wide, and 15mm high; the heat insulation box 5 is made of refractory material, and the refractory material includes the following substances in mass percentage: 83.4% CaO, 0.8% BN, 2.9% MnO, 1.9% Al 2 o 3 , 3.7% ZrB 2 , 2.3% SiO 2 .

Embodiment 3

[0062] The steps of the method for detecting the working state of the nozzle in the second cooling zone of continuous casting in this embodiment are basically the same as those in Embodiment 1, except that in step (D), the set value is 1.5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com