Circumference error compensation method using laser direct feedback

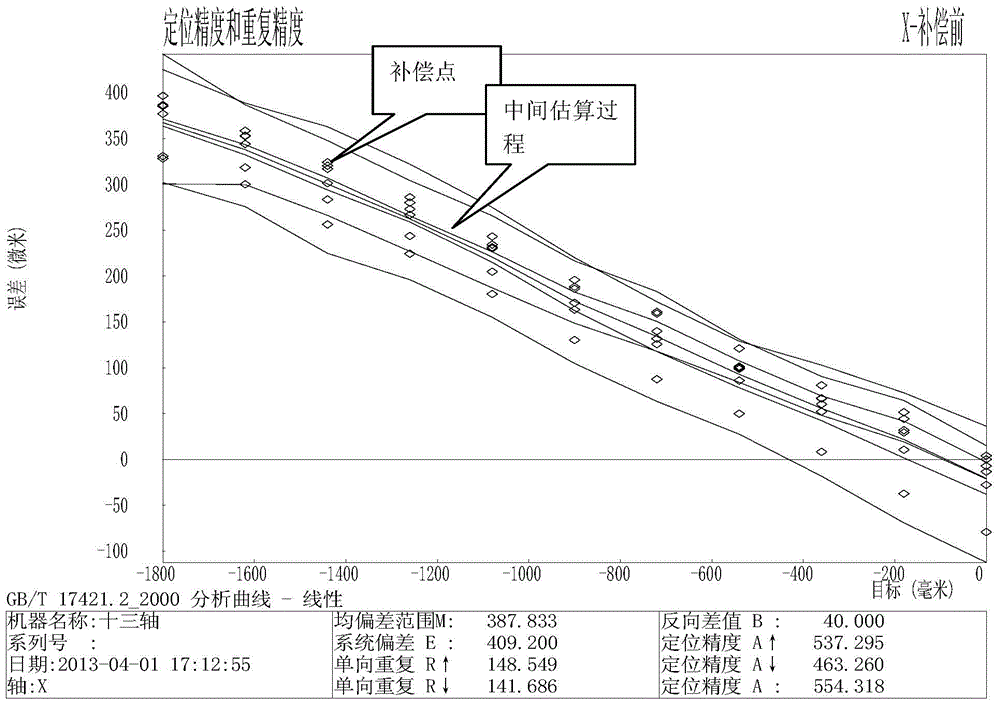

An error compensation, laser direct technology, applied in the field of circular error compensation, can solve the problems of excessive points that cannot be compensated and recorded, slow measurement, uncertain compensation data, etc., to improve the efficiency of linear position compensation, simple structure, and linear compensation accuracy. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

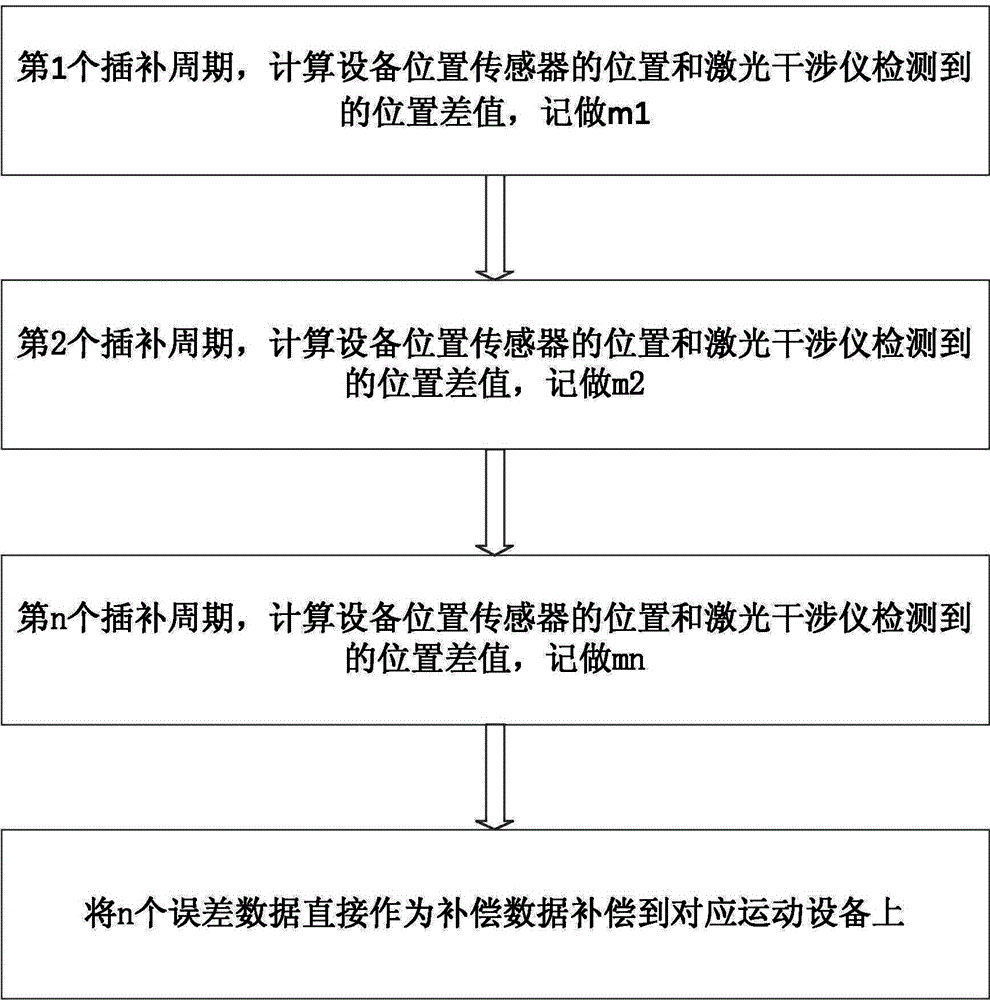

[0024] Such as figure 2 Shown: a circular error compensation method using laser direct feedback, using the laser interferometer motion position information output interface, directly introduce the precise position of the laser interferometer into the motion control system, the entire error compensation process becomes

[0025] First, connect the position information output interface of the laser interferometer to the motion control system to read the current circular motion position I of the machine tool detected by the laser interferometer.

[0026] Write a uniform circular running program corresponding to the measuring unit. Use the numerical control system to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com