Self-tapping thread bushing tool

A self-tapping thread and bushing technology, applied in the direction of motor tools, manufacturing tools, etc., can solve problems such as wear, screw thread strain, and scrapping of the whole product, and achieve reliable work, fast installation, and strong on-site versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

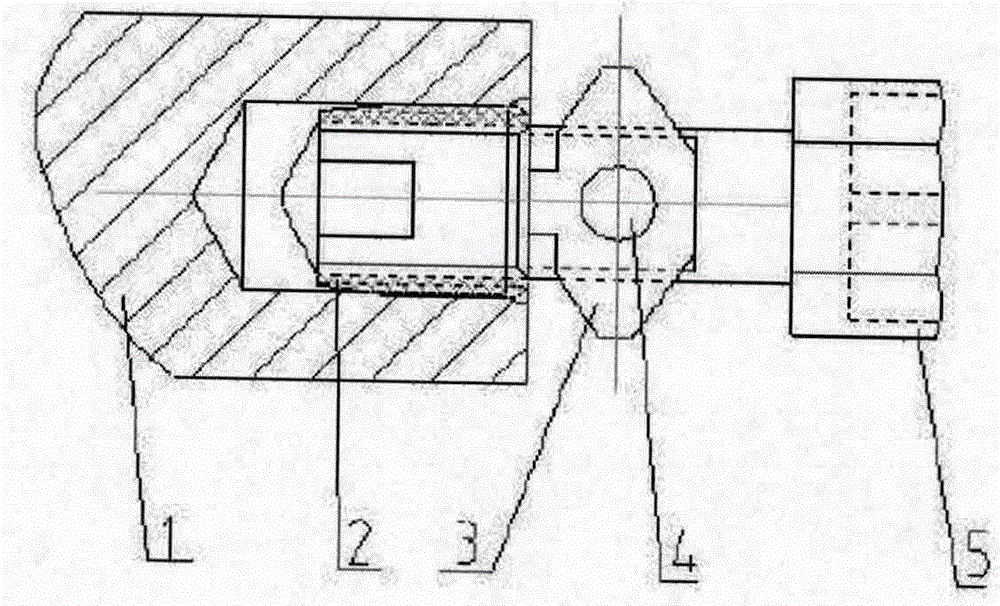

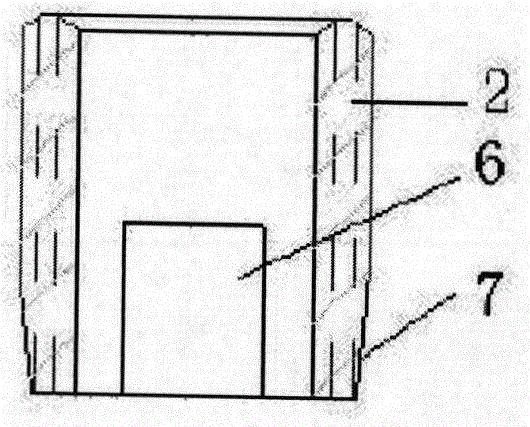

[0009] One end of the screw body 5 is provided with an external thread that cooperates with the internal thread of the self-tapping threaded bush, the middle section of the rod body is provided with a table that cooperates with the limit block 3, and the other end is provided with a square hole that cooperates with a standard pneumatic or electric tool wrench. The limit block 3 is fixed on the table top of the rod body in the middle section of the screw body 5 through the pin shaft 4 . The front end 7 of the self-tapping threaded bush 2 is designed in the form of a taper, which is convenient for playing a guiding role when the self-tapping threaded bush enters the product. The front end 7 of the self-tapping threaded bush 2 is designed in the form of two symmetrical openings 6. The design of the openings 6 is mainly to cooperate with the base of the aluminum alloy product 1. The self-tapping thread bushing 2 is tapped into the interior of the aluminum alloy product 1 . Accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com