Paper separating mechanism with efficient paper feeding function

A paper separation and paper feeding technology, applied to paper/cardboard containers, pile separation, object separation, etc., can solve the problems of uneconomical production, lack of time for paper transportation, messy paper output, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

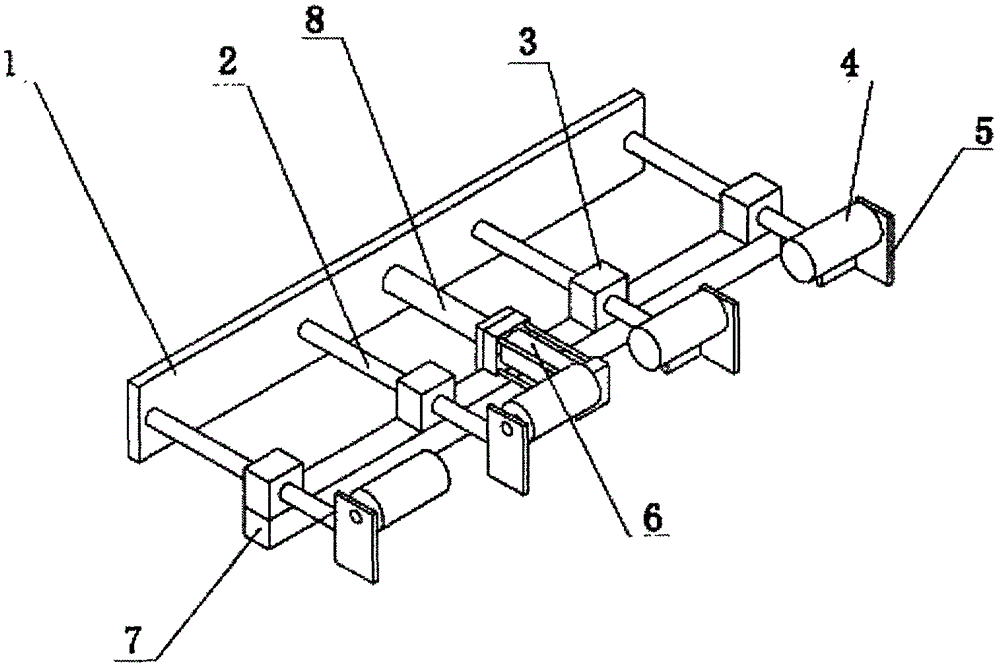

[0010] In the illustrated paper separation mechanism that can realize efficient paper feeding, a connecting seat is provided at the middle position of the frame 7, and a through hole is provided in the center of the connecting seat, and the power unit 6 is fixedly connected to the connecting seat. In this embodiment The power unit 6 is a cylinder, the piston rod of the cylinder is fixedly connected to one end of the push rod 8 through a coupling, and the other end of the push rod 8 is fixedly connected to the middle position of the lifting cardboard 1, and is symmetrically fixed on the frame 7 on both sides of the connecting seat Four sliding seats 3 are installed, and the sliding seats 3 are evenly connected to the sliding rod 2. The sliding rod 2 passes through the inner hole of the sliding seat 3 and extends to both ends. The extended end of the sliding rod 2 is fixedly connected to the cardboard 1. The extended end on the other side of the slide bar 2 is fixedly connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com