Separation extracting method of purified aged asphalt

A technology of aging asphalt and old asphalt, which is applied to building components, building insulation materials, buildings, etc., and can solve problems such as low centrifugal force, affecting the accuracy of original data, and inability to separate asphalt cleanly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

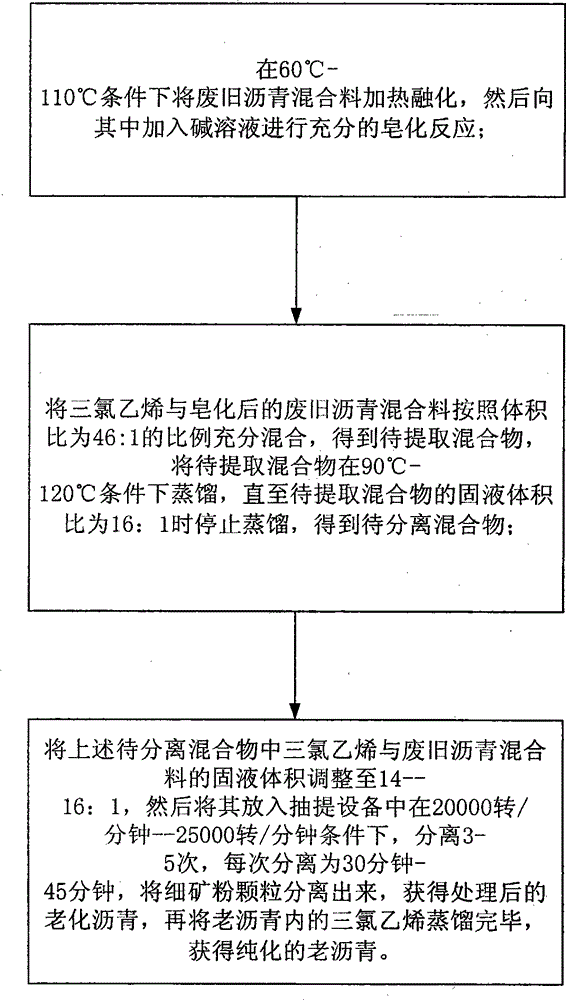

Method used

Image

Examples

Embodiment 1

[0046] Foaming, saponification and oil extraction operations are carried out first;

[0047] The ratio of the amount of trichlorethylene to the aged asphalt in the waste asphalt mixture is 46:1;

[0048] The mixing ratio of distilled trichlorethylene solution and aged asphalt is 14--16:1;

[0049] High-speed centrifuge 20000 rpm - 25000 rpm high speed, 55000x g - 65000x g centrifugal force;

[0050] The number of centrifugation is 3-5 times, and the centrifugation time is 30 minutes each time;

[0051] The high-temperature calcination method is used to detect that there is no mineral powder residue, and the aged asphalt meets the design requirements.

Embodiment 2

[0053] Foaming, saponification and oil extraction operations are carried out first;

[0054] The ratio of the amount of trichlorethylene to the aged asphalt in the waste asphalt mixture is 46:1;

[0055] The mixing ratio of distilled trichlorethylene solution and aged asphalt is 14--16:1;

[0056] High speed centrifuge 15000 rpm - 20000 rpm high speed, 30000x g - 40000x g centrifugal force;

[0057] The number of centrifugation is 3-5 times, and the centrifugation time is 30 minutes each time;

[0058] A small amount of mineral powder residue is detected by high-temperature calcination method.

Embodiment 3

[0060] Foaming, saponification and oil extraction operations are carried out first;

[0061] The ratio of the amount of vinyl chloride to the aged asphalt in the waste asphalt mixture is 35:1;

[0062] The mixing ratio of distilled trichlorethylene solution and aged asphalt is 10--12:1;

[0063] High-speed centrifuge 20000 rpm - 25000 rpm high speed, 55000x g - 65000x g centrifugal force;

[0064] The number of centrifugation is 3-5 times, and the centrifugation time is 30 minutes each time;

[0065] Use the high temperature calcination method to detect the residue of ore powder.

[0066] The present invention has undergone a large number of tests with different rotating speeds and different solution ratios, and the method of the present invention can completely solve the problem of residual mineral powder particles in the aged extracted asphalt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com